|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

yakman285(at)gmail.com

Guest

|

Posted: Tue Dec 08, 2020 3:14 am Post subject: Yak-List Digest: 4 Msgs - 12/07/20 Posted: Tue Dec 08, 2020 3:14 am Post subject: Yak-List Digest: 4 Msgs - 12/07/20 |

|

|

Some years back the popular fix was to file some notches in the flapper valves. To me that seemed to defeat the purpose. Using a little MMO in the fuel made me feel better anyway.

Craig Payne

On Tue, Dec 8, 2020 at 2:53 AM Yak-List Digest Server <yak-list(at)matronics.com (yak-list(at)matronics.com)> wrote:

| Quote: | *

=========================

Online Versions of Today's List Digest Archive

=========================

Today's complete Yak-List Digest can also be found in either of the

two Web Links listed below. The .html file includes the Digest formatted

in HTML for viewing with a web browser and features Hyperlinked Indexes

and Message Navigation. The .txt file includes the plain ASCII version

of the Yak-List Digest and can be viewed with a generic text editor

such as Notepad or with a web browser.

HTML Version:

http://www.matronics.com/digest/digestview.php?Style=82701&View=html&Chapter=2020-12-07&Archive=Yak

Text Version:

http://www.matronics.com/digest/digestview.php?Style=82701&View=txt&Chapter=2020-12-07&Archive=Yak

=======================

EMail Version of Today's List Digest Archive

=======================

----------------------------------------------------------

Yak-List Digest Archive

---

Total Messages Posted Mon 12/07/20: 4

----------------------------------------------------------

Today's Message Index:

----------------------

1. 10:24 AM - Fw: CJ6 uneven fuel flow (Walter Lannon)

2. 12:28 PM - Re: Fw: CJ6 uneven fuel flow (JON BLAKE)

3. 01:30 PM - Re: Fw: CJ6 uneven fuel flow (Larry Pine)

4. 09:06 PM - Re: Fw: CJ6 uneven fuel flow (Walter Lannon)

________________________________Â Message 1Â _____________________________________

Time: 10:24:05 AM PST US

From: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Subject: Fw: CJ6 uneven fuel flow

From: Walter Lannon

Sent: Sunday, December 06, 2020 9:09 PM

Subject: CJ6 uneven fuel flow

Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should

respond but since it will be a rather long diatribe I thought the Yak

List might be a better venue.

My aircraft is a 1966 model CJ6a, one of four I imported from China in

1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!)Â It was a 6 year (off and on) 100% restoration

including the fuel system where I found some questionable design

features. During this period (from 1993) I also licensed a few others

and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.

Many people have noted the fuel feeds from the LH tank first. That is

not surprising since the LHÂ vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect

favoring LH flow via the shorter fuel feed line to the header tank. Â

The major design problem rests with the header tank flapper valves.Â

There are three of these valves in the aircraft. One is in the fuel

line from the header tank to the fuel pump. It=99s sole purpose

is to direct fuel

from the emerg. (wobble) pump to the engine fuel pump while preventing

reverse flow back to the header tank. This is the type of function the

valve is designed for and it works perfectly because there is a

distinct difference in pressure on each side.Â

With reference to the attached photos note the diameter of the flapper

as compared to the diameter of the incoming fuel hole. A true

=9Cflapper=9D valve is meant to open (or close) with fuel

flow but pressure, though relatively small, is a factor.  If we start

with equal fuel one flapper will open (probably the LH). In theory as

the pressure from the LH tank and the header tank is reduced at some

point the RH will open and the cycle will repeat.

But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface

impacted by the RH fuel.

I did some rough math based on tank volume and pressures, etc. and came

to the following conclusion: - The major reason this system sort of

works is called turbulence! If you could take off, climb and fly a trip

with never a bump of any kind you will be out of gas with a full RH

tank.

As you probably noted I have modified the valves to allow closing

pressure to impact some of the opening surface. My typical fuel

imbalance is less than 5 lts. For me this is a hand filing operation

(though a CNC genius could probably do it).  You MUST retain a seating

ring of the original closing surface. If you change that it will never

close properly again due to the geometry.

One of the un modified valve photos shows a Chinese character on a

wrench flat. In English this reads =9CHINGE=9D and must be

at the top. Improper positioning could well be the cause of serious

imbalance.

Cheers;

Walt

________________________________Â Message 2Â _____________________________________

Time: 12:28:05 PM PST US

From: JON BLAKE <saber369(at)comcast.net (saber369(at)comcast.net)>

Subject: Re: Fw: CJ6 uneven fuel flow

Good info Walt... many thanks.Â

When I first bought my CJ 15 years ago, I was told to wrap the vent on the

belly with a fine mesh screen to keep the bugs out. I was also told that t

he vents going out to each wing tips were installed by Yakity Yaks to help

prevent a bug or other debris from causing fuel starvation. Is that true?

Can you shed any more light on those vents?

Jon Blake

Saber369(at)comcast.net (Saber369(at)comcast.net)

>Â Â Â On 12/07/2020 12:22 PM Walter Lannon <wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â From: Walter Lannon mailto:wlannon(at)shaw.ca (wlannon(at)shaw.ca)

>Â Â Â Sent: Sunday, December 06, 2020 9:09 PM

>Â Â Â To: yaklist(at)matronics.com (yaklist(at)matronics.com) mailto:yaklist(at)matronics.com (yaklist(at)matronics.com)

>Â Â Â Subject: CJ6 uneven fuel flow

>Â Â Â

>Â Â Â Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should re

spond but since it will be a rather long diatribe I thought the Yak List mi

ght be a better venue.

>Â Â Â

>Â Â Â My aircraft is a 1966 model CJ6a, one of four I imported from China i

n 1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!)Â It was a 6 year (off and on) 100% restoration in

cluding the fuel system where I found some questionable design features. D

uring this period (from 1993) I also licensed a few others and found it was

necessary to do a hot soap and water flush of the fuel vent system to remo

ve bug debris.

>Â Â Â

>   Many people have noted the fuel feeds from the LH tank first. That i

s not surprising since the LHÂ vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

>Â Â Â tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect favor

ing LH flow via the shorter fuel feed line to the header tank. Â

>Â Â Â

>Â Â Â The major design problem rests with the header tank flapper valves.Â

There are three of these valves in the aircraft. One is in the fuel line f

rom the header tank to the fuel pump. It=99s sole purpose is to dire

ct fuel

>Â Â Â from the emerg. (wobble) pump to the engine fuel pump while preventin

g reverse flow back to the header tank. This is the type of function the v

alve is designed for and it works perfectly because there is a

>Â Â Â distinct difference in pressure on each side.

>Â Â Â

>Â Â Â With reference to the attached photos note the diameter of the flappe

r as compared to the diameter of the incoming fuel hole. A true =9Cf

lapper=9D valve is meant to open (or close) with fuel flow but pressu

re, though relatively small, is a factor.  If we start with equal fuel one

flapper will open (probably the LH). In theory as the pressure from the L

H tank and the header tank is reduced at some point the RH will open and th

e cycle will repeat.

>Â Â Â But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface impa

cted by the RH fuel.

>Â Â Â

>Â Â Â I did some rough math based on tank volume and pressures, etc. and ca

me to the following conclusion: - The major reason this system sort of work

s is called turbulence! If you could take off, climb and fly a trip with n

ever a bump of any kind you will be out of gas with a full RH tank.

>Â Â Â

>Â Â Â As you probably noted I have modified the valves to allow closing pre

ssure to impact some of the opening surface. My typical fuel imbalance is

less than 5 lts. For me this is a hand filing operation (though a CNC geni

us could probably do it).  You MUST retain a seating ring of the original

closing surface. If you change that it will never close properly again due

to the geometry.

>Â Â Â

>Â Â Â One of the un modified valve photos shows a Chinese character on a wr

ench flat. In English this reads =9CHINGE=9D and must be at th

e top. Improper positioning could well be the cause of serious imbalance.

>Â Â Â

>Â Â Â

>Â Â Â Cheers;

>Â Â Â Walt

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â

>

________________________________Â Message 3Â _____________________________________

Time: 01:30:00 PM PST US

From: Larry Pine <threein60(at)yahoo.com (threein60(at)yahoo.com)>

Subject: Re: Fw: CJ6 uneven fuel flow

Great write-up on this. Let me add a little learned knowledge to this discu

ssion. I have no issues with what Walt stated but a few years ago I had fue

l starvation while on the ground. I could start the engine on my electrical

boost pump but the minute I shut it off, the engine would die. I checked f

uel levels, I removed and cleaned the fuel strainer and checked for flow, s

till nothing. Only when I removed the flapper valve under the floor, the on

e that feeds the wobble pump, I found the hinge in this flapper was worn an

d could rotate to a place where it would get stuck closed. This was the fir

st I have ever hear of this happening. I cleaned and lightly refaced both t

he flapper and flapper seat. I then replaced the worn hinge pivot rod with

a new brass one. I have plans to take apart this valve again during this mo

nths annual and see if these is any wear taking place on the hinge rod. Luc

ky I found this on the ground but confident had this happened in flight, my

electric driven pump would have supplied enough fuel to get me back safely

. Still some thing that should be examined.

I have bladder tanks so my vents are extended to their respective wing tips

with a separate vent for the header tank. I find that I tend to fly more p

ressure on my left rudder because my knee board is on my right and lifting

my right knee a little makes writing easier. This tends to cause a noticeab

le fuel difference over a 2 hour period. I know, bad pilot bad. Very early

on before I had my bladder tanks installed, I had to do an emergency divert

because my one tank was almost dry and the opposite tank wasn't moving the

needle yet. Only after landing I noticed the needle move. Constant fuel ma

nagement has become the norm. I optioned to not install the vent shut off v

alues after and incident I had with another RPAer. This pilot closed one of

his vents to overcome the fuel flow difference and forgot to open the vent

again. On roll out with the engine pulled to ideal, the engine died on the

runway. It would start but than die again. When we got it to parking, we n

oticed one bladder tank was sucked flat and dry..... The same side with the

closed vent. Human factors are human factors! Unless you design a system t

o incorporate some warning when the pressure builds or the vent is closed i

ndication, this only complicates memory items that needs to be attended and

eventually can lead to failures.

Larry Pine   On Monday, December 7, 2020, 10:48:19 AM PST, Walter Lannon

<wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:Â

=C2-=C2-From: Walter Lannon Sent: Sunday, December 06, 2020 9:09 PMTo:

yaklist(at)matronics.com (yaklist(at)matronics.com) Subject: CJ6 uneven fuel flow=C2-Currently there i

s a lot of interest in the above subject on the Red Star site.=C2- Since

I have some experience in this area I thought I should respond but since it

will be a rather long diatribe I thought the Yak List might be a better ve

nue.=C2-My aircraft is a 1966 model CJ6a, one of four I imported from Chi

na in 1993.=C2- Did not start my own restoration until after selling my H

arvard 4 in 2006 (after 30 years!)=C2- It was a 6 year (off and on) 100%

restoration including the fuel system where I found some questionable desig

n features.=C2- During this period (from 1993) I also licensed a few othe

rs and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.=C2-Many people have noted the fuel feed

s from the LH tank first.=C2- That is not surprising since the LH=C2- v

ent system is much shorter than the RH and the tube is 8 mm (6 mm ID) for b

oth.=C2- Not a huge problem as long as the tubing is internally clean and

totally free of any damage that could restrict air flow. This is critical!

=C2- There is also some minor effect favoring LH flow via the shorter fue

l feed line to the header tank.=C2-=C2-=C2- =C2-The major design pr

oblem rests with the header tank flapper valves.=C2- There are three of t

hese valves in the aircraft.=C2- One is in the fuel line from the header

tank to the fuel pump.=C2- It=99s sole purpose is to direct fuelfro

m the emerg. (wobble) pump to the engine fuel pump while preventing reverse

flow back to the header tank.=C2- This is the type of function the valve

is designed for and it works perfectly because there is a distinct differe

nce in pressure on each side.=C2- =C2-With reference to the attached ph

otos note the diameter of the flapper as compared to the diameter of the in

coming fuel hole.=C2- A true =9Cflapper=9D valve is meant to

open (or close) with fuel flow but pressure, though relatively small, is a

factor.=C2-=C2- If we start with equal fuel one flapper will open (prob

ably the LH).=C2- In theory as the pressure from the LH tank and the head

er tank is reduced at some point the RH will open and the cycle will repeat

.But, in fact, the LH plus the header tank fuel is actually applying a forc

e to the valve surface roughly double that of the smaller surface impacted

by the RH fuel.=C2-I did some rough math based on tank volume and pressur

es, etc. and came to the following conclusion: - The major reason this syst

em sort of works is called turbulence!=C2- If you could take off, climb a

nd fly a trip with never a bump of any kind you will be out of gas with a f

ull RH tank. =C2-As you probably noted I have modified the valves to allo

w closing pressure to impact some of the opening surface.=C2- My typical

fuel imbalance is less than 5 lts.=C2- For me this is a hand filing opera

tion (though a CNC genius could probably do it).=C2-=C2- You MUST retai

n a seating ring of the original closing surface.=C2- If you change that

it will never close properly again due to the geometry. =C2-One of the un

modified valve photos shows a Chinese character on a wrench flat.=C2- In

English this reads =9CHINGE=9D and must be at the top.=C2- I

mproper positioning could well be the cause of serious imbalance.=C2-=C2

-Cheers;Walt=C2-=C2-=C2-=C2-=C2-Â

________________________________Â Message 4Â _____________________________________

Time: 09:06:58 PM PST US

From: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Subject: Re: Fw: CJ6 uneven fuel flow

Hi Jon;

Thank you!

I have never seen the wing tip vent installation but assume that was

it=99s purpose. Should work as long as it terminates in a

positive (or neutral) pressure area.

I seem to remember from my misspent youth that Cessna produced a lightly

spring loaded vent valve that was installed in the fuel cap. I have

been intending to

track that down for years!!!Â

We really should have an emergency vent of some type in the CJ. ONE is

not enough!  In the T6/Harvard (and most aircraft) each tank is

separately vented.

Over the years I have seen three T6 fuel tanks where you could touch the

tank bottom from the filler hole due to a plugged vent.

Cheers;

Walt Â

From: JON BLAKE

Sent: Monday, December 07, 2020 12:26 PM

Subject: Re: Fw: CJ6 uneven fuel flow

Good info Walt... many thanks. Â

When I first bought my CJ 15 years ago, I was told to wrap the vent on

the belly with a fine mesh screen to keep the bugs out. I was also told

that the vents going out to each wing tips were installed by Yakity Yaks

to help prevent a bug or other debris from causing fuel starvation. Is

that true? Can you shed any more light on those vents?Â

Jon Blake

Saber369(at)comcast.net (Saber369(at)comcast.net)

On 12/07/2020 12:22 PM Walter Lannon <wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

From: Walter Lannon

Sent: Sunday, December 06, 2020 9:09 PM

To: yaklist(at)matronics.com (yaklist(at)matronics.com)

Subject: CJ6 uneven fuel flow

Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should

respond but since it will be a rather long diatribe I thought the Yak

List might be a better venue.

My aircraft is a 1966 model CJ6a, one of four I imported from China in

1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!)Â It was a 6 year (off and on) 100% restoration

including the fuel system where I found some questionable design

features. During this period (from 1993) I also licensed a few others

and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.

Many people have noted the fuel feeds from the LH tank first. That is

not surprising since the LHÂ vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect

favoring LH flow via the shorter fuel feed line to the header tank. Â

The major design problem rests with the header tank flapper valves.Â

There are three of these valves in the aircraft. One is in the fuel

line from the header tank to the fuel pump. It=99s sole purpose

is to direct fuel

from the emerg. (wobble) pump to the engine fuel pump while preventing

reverse flow back to the header tank. This is the type of function the

valve is designed for and it works perfectly because there is a

distinct difference in pressure on each side.Â

With reference to the attached photos note the diameter of the flapper

as compared to the diameter of the incoming fuel hole. A true

=9Cflapper=9D valve is meant to open (or close) with fuel

flow but pressure, though relatively small, is a factor.  If we start

with equal fuel one flapper will open (probably the LH). In theory as

the pressure from the LH tank and the header tank is reduced at some

point the RH will open and the cycle will repeat.

But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface

impacted by the RH fuel.

I did some rough math based on tank volume and pressures, etc. and

came to the following conclusion: - The major reason this system sort of

works is called turbulence! If you could take off, climb and fly a trip

with never a bump of any kind you will be out of gas with a full RH

tank.

As you probably noted I have modified the valves to allow closing

pressure to impact some of the opening surface. My typical fuel

imbalance is less than 5 lts. For me this is a hand filing operation

(though a CNC genius could probably do it).  You MUST retain a seating

ring of the original closing surface. If you change that it will never

close properly again due to the geometry.

One of the un modified valve photos shows a Chinese character on a

wrench flat. In English this reads =9CHINGE=9D and must be

at the top. Improper positioning could well be the cause of serious

imbalance.

Cheers;

Walt

===========

List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Yak-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

pennington.construction.i

Guest

|

Posted: Tue Dec 08, 2020 3:56 am Post subject: Yak-List Digest: 4 Msgs - 12/07/20 Posted: Tue Dec 08, 2020 3:56 am Post subject: Yak-List Digest: 4 Msgs - 12/07/20 |

|

|

Good Morning Yak List

I fly a CJ6 with the bladders so not stock tank or vent piping.

When I was having this problem I consulted another CJ owner with a bladder system ( you know who you are and thank you) and he pointed out after some photos were sent to him that my tube extending from the bottom of the plane was most likely not long enough to be in the slipstream and apply the pressure to the vent system and the top of the fuel in the tanks. I extended the tube about 3/8" farther down and it cured my tank imbalance. Also, what I do about every third flight or so is I put a hose on the vent tube extending from the bottom of the plane and open one fuel tank at a time and blow through the system and clear the vent system back to the tank. I close that tank and open the other and repeat. Sometimes I can tell I am clearing something from the vent system back into the tank. Most likely fuel. I dont fly straight and level very long when I go out. Â

I make sure the ball is centered and pay attention to wings level and I rarely come back with a fuel imbalance. I did inspect the flapper valves during one of my condition inspections and made sure they were clean and freely moving but made no modifications to them.  I usually refuel after the flight and before I put the plane in the hangar. Usually the tanks are within 1 to 2 gallons of each other... A couple of times, I have come back after a couple of hours of flight time and one tank was down much farther than the other. Before I put the plane away , I put the hose on the vent tube and could tell one tank's vent system was plugged. So the imbalance made sense.

Hope this helps. Â

Mark

N621CJ

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

On Tue, Dec 8, 2020 at 6:20 AM Craig Payne <yakman285(at)gmail.com (yakman285(at)gmail.com)> wrote:

| Quote: | Some years back the popular fix was to file some notches in the flapper valves. To me that seemed to defeat the purpose. Using a little MMO in the fuel made me feel better anyway.

Craig Payne

On Tue, Dec 8, 2020 at 2:53 AM Yak-List Digest Server <yak-list(at)matronics.com (yak-list(at)matronics.com)> wrote:

| Quote: | *

=========================

Online Versions of Today's List Digest Archive

=========================

Today's complete Yak-List Digest can also be found in either of the

two Web Links listed below. The .html file includes the Digest formatted

in HTML for viewing with a web browser and features Hyperlinked Indexes

and Message Navigation. The .txt file includes the plain ASCII version

of the Yak-List Digest and can be viewed with a generic text editor

such as Notepad or with a web browser.

HTML Version:

http://www.matronics.com/digest/digestview.php?Style=82701&View=html&Chapter=2020-12-07&Archive=Yak

Text Version:

http://www.matronics.com/digest/digestview.php?Style=82701&View=txt&Chapter=2020-12-07&Archive=Yak

=======================

EMail Version of Today's List Digest Archive

=======================

----------------------------------------------------------

Yak-List Digest Archive

---

Total Messages Posted Mon 12/07/20: 4

----------------------------------------------------------

Today's Message Index:

----------------------

1. 10:24 AM - Fw: CJ6 uneven fuel flow (Walter Lannon)

2. 12:28 PM - Re: Fw: CJ6 uneven fuel flow (JON BLAKE)

3. 01:30 PM - Re: Fw: CJ6 uneven fuel flow (Larry Pine)

4. 09:06 PM - Re: Fw: CJ6 uneven fuel flow (Walter Lannon)

________________________________Â Message 1Â _____________________________________

Time: 10:24:05 AM PST US

From: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Subject: Fw: CJ6 uneven fuel flow

From: Walter Lannon

Sent: Sunday, December 06, 2020 9:09 PM

Subject: CJ6 uneven fuel flow

Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should

respond but since it will be a rather long diatribe I thought the Yak

List might be a better venue.

My aircraft is a 1966 model CJ6a, one of four I imported from China in

1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!)Â It was a 6 year (off and on) 100% restoration

including the fuel system where I found some questionable design

features. During this period (from 1993) I also licensed a few others

and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.

Many people have noted the fuel feeds from the LH tank first. That is

not surprising since the LHÂ vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect

favoring LH flow via the shorter fuel feed line to the header tank. Â

The major design problem rests with the header tank flapper valves.Â

There are three of these valves in the aircraft. One is in the fuel

line from the header tank to the fuel pump. It=99s sole purpose

is to direct fuel

from the emerg. (wobble) pump to the engine fuel pump while preventing

reverse flow back to the header tank. This is the type of function the

valve is designed for and it works perfectly because there is a

distinct difference in pressure on each side.Â

With reference to the attached photos note the diameter of the flapper

as compared to the diameter of the incoming fuel hole. A true

=9Cflapper=9D valve is meant to open (or close) with fuel

flow but pressure, though relatively small, is a factor.  If we start

with equal fuel one flapper will open (probably the LH). In theory as

the pressure from the LH tank and the header tank is reduced at some

point the RH will open and the cycle will repeat.

But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface

impacted by the RH fuel.

I did some rough math based on tank volume and pressures, etc. and came

to the following conclusion: - The major reason this system sort of

works is called turbulence! If you could take off, climb and fly a trip

with never a bump of any kind you will be out of gas with a full RH

tank.

As you probably noted I have modified the valves to allow closing

pressure to impact some of the opening surface. My typical fuel

imbalance is less than 5 lts. For me this is a hand filing operation

(though a CNC genius could probably do it).  You MUST retain a seating

ring of the original closing surface. If you change that it will never

close properly again due to the geometry.

One of the un modified valve photos shows a Chinese character on a

wrench flat. In English this reads =9CHINGE=9D and must be

at the top. Improper positioning could well be the cause of serious

imbalance.

Cheers;

Walt

________________________________Â Message 2Â _____________________________________

Time: 12:28:05 PM PST US

From: JON BLAKE <saber369(at)comcast.net (saber369(at)comcast.net)>

Subject: Re: Fw: CJ6 uneven fuel flow

Good info Walt... many thanks.Â

When I first bought my CJ 15 years ago, I was told to wrap the vent on the

belly with a fine mesh screen to keep the bugs out. I was also told that t

he vents going out to each wing tips were installed by Yakity Yaks to help

prevent a bug or other debris from causing fuel starvation. Is that true?

Can you shed any more light on those vents?

Jon Blake

Saber369(at)comcast.net (Saber369(at)comcast.net)

>Â Â Â On 12/07/2020 12:22 PM Walter Lannon <wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â From: Walter Lannon mailto:wlannon(at)shaw.ca (wlannon(at)shaw.ca)

>Â Â Â Sent: Sunday, December 06, 2020 9:09 PM

>Â Â Â To: yaklist(at)matronics.com (yaklist(at)matronics.com) mailto:yaklist(at)matronics.com (yaklist(at)matronics.com)

>Â Â Â Subject: CJ6 uneven fuel flow

>Â Â Â

>Â Â Â Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should re

spond but since it will be a rather long diatribe I thought the Yak List mi

ght be a better venue.

>Â Â Â

>Â Â Â My aircraft is a 1966 model CJ6a, one of four I imported from China i

n 1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!)Â It was a 6 year (off and on) 100% restoration in

cluding the fuel system where I found some questionable design features. D

uring this period (from 1993) I also licensed a few others and found it was

necessary to do a hot soap and water flush of the fuel vent system to remo

ve bug debris.

>Â Â Â

>   Many people have noted the fuel feeds from the LH tank first. That i

s not surprising since the LHÂ vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

>Â Â Â tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect favor

ing LH flow via the shorter fuel feed line to the header tank. Â

>Â Â Â

>Â Â Â The major design problem rests with the header tank flapper valves.Â

There are three of these valves in the aircraft. One is in the fuel line f

rom the header tank to the fuel pump. It=99s sole purpose is to dire

ct fuel

>Â Â Â from the emerg. (wobble) pump to the engine fuel pump while preventin

g reverse flow back to the header tank. This is the type of function the v

alve is designed for and it works perfectly because there is a

>Â Â Â distinct difference in pressure on each side.

>Â Â Â

>Â Â Â With reference to the attached photos note the diameter of the flappe

r as compared to the diameter of the incoming fuel hole. A true =9Cf

lapper=9D valve is meant to open (or close) with fuel flow but pressu

re, though relatively small, is a factor.  If we start with equal fuel one

flapper will open (probably the LH). In theory as the pressure from the L

H tank and the header tank is reduced at some point the RH will open and th

e cycle will repeat.

>Â Â Â But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface impa

cted by the RH fuel.

>Â Â Â

>Â Â Â I did some rough math based on tank volume and pressures, etc. and ca

me to the following conclusion: - The major reason this system sort of work

s is called turbulence! If you could take off, climb and fly a trip with n

ever a bump of any kind you will be out of gas with a full RH tank.

>Â Â Â

>Â Â Â As you probably noted I have modified the valves to allow closing pre

ssure to impact some of the opening surface. My typical fuel imbalance is

less than 5 lts. For me this is a hand filing operation (though a CNC geni

us could probably do it).  You MUST retain a seating ring of the original

closing surface. If you change that it will never close properly again due

to the geometry.

>Â Â Â

>Â Â Â One of the un modified valve photos shows a Chinese character on a wr

ench flat. In English this reads =9CHINGE=9D and must be at th

e top. Improper positioning could well be the cause of serious imbalance.

>Â Â Â

>Â Â Â

>Â Â Â Cheers;

>Â Â Â Walt

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â

>Â Â Â

>

________________________________Â Message 3Â _____________________________________

Time: 01:30:00 PM PST US

From: Larry Pine <threein60(at)yahoo.com (threein60(at)yahoo.com)>

Subject: Re: Fw: CJ6 uneven fuel flow

Great write-up on this. Let me add a little learned knowledge to this discu

ssion. I have no issues with what Walt stated but a few years ago I had fue

l starvation while on the ground. I could start the engine on my electrical

boost pump but the minute I shut it off, the engine would die. I checked f

uel levels, I removed and cleaned the fuel strainer and checked for flow, s

till nothing. Only when I removed the flapper valve under the floor, the on

e that feeds the wobble pump, I found the hinge in this flapper was worn an

d could rotate to a place where it would get stuck closed. This was the fir

st I have ever hear of this happening. I cleaned and lightly refaced both t

he flapper and flapper seat. I then replaced the worn hinge pivot rod with

a new brass one. I have plans to take apart this valve again during this mo

nths annual and see if these is any wear taking place on the hinge rod. Luc

ky I found this on the ground but confident had this happened in flight, my

electric driven pump would have supplied enough fuel to get me back safely

. Still some thing that should be examined.

I have bladder tanks so my vents are extended to their respective wing tips

with a separate vent for the header tank. I find that I tend to fly more p

ressure on my left rudder because my knee board is on my right and lifting

my right knee a little makes writing easier. This tends to cause a noticeab

le fuel difference over a 2 hour period. I know, bad pilot bad. Very early

on before I had my bladder tanks installed, I had to do an emergency divert

because my one tank was almost dry and the opposite tank wasn't moving the

needle yet. Only after landing I noticed the needle move. Constant fuel ma

nagement has become the norm. I optioned to not install the vent shut off v

alues after and incident I had with another RPAer. This pilot closed one of

his vents to overcome the fuel flow difference and forgot to open the vent

again. On roll out with the engine pulled to ideal, the engine died on the

runway. It would start but than die again. When we got it to parking, we n

oticed one bladder tank was sucked flat and dry..... The same side with the

closed vent. Human factors are human factors! Unless you design a system t

o incorporate some warning when the pressure builds or the vent is closed i

ndication, this only complicates memory items that needs to be attended and

eventually can lead to failures.

Larry Pine   On Monday, December 7, 2020, 10:48:19 AM PST, Walter Lannon

<wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:Â

=C2-=C2-From: Walter Lannon Sent: Sunday, December 06, 2020 9:09 PMTo:

yaklist(at)matronics.com (yaklist(at)matronics.com) Subject: CJ6 uneven fuel flow=C2-Currently there i

s a lot of interest in the above subject on the Red Star site.=C2- Since

I have some experience in this area I thought I should respond but since it

will be a rather long diatribe I thought the Yak List might be a better ve

nue.=C2-My aircraft is a 1966 model CJ6a, one of four I imported from Chi

na in 1993.=C2- Did not start my own restoration until after selling my H

arvard 4 in 2006 (after 30 years!)=C2- It was a 6 year (off and on) 100%

restoration including the fuel system where I found some questionable desig

n features.=C2- During this period (from 1993) I also licensed a few othe

rs and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.=C2-Many people have noted the fuel feed

s from the LH tank first.=C2- That is not surprising since the LH=C2- v

ent system is much shorter than the RH and the tube is 8 mm (6 mm ID) for b

oth.=C2- Not a huge problem as long as the tubing is internally clean and

totally free of any damage that could restrict air flow. This is critical!

=C2- There is also some minor effect favoring LH flow via the shorter fue

l feed line to the header tank.=C2-=C2-=C2- =C2-The major design pr

oblem rests with the header tank flapper valves.=C2- There are three of t

hese valves in the aircraft.=C2- One is in the fuel line from the header

tank to the fuel pump.=C2- It=99s sole purpose is to direct fuelfro

m the emerg. (wobble) pump to the engine fuel pump while preventing reverse

flow back to the header tank.=C2- This is the type of function the valve

is designed for and it works perfectly because there is a distinct differe

nce in pressure on each side.=C2- =C2-With reference to the attached ph

otos note the diameter of the flapper as compared to the diameter of the in

coming fuel hole.=C2- A true =9Cflapper=9D valve is meant to

open (or close) with fuel flow but pressure, though relatively small, is a

factor.=C2-=C2- If we start with equal fuel one flapper will open (prob

ably the LH).=C2- In theory as the pressure from the LH tank and the head

er tank is reduced at some point the RH will open and the cycle will repeat

.But, in fact, the LH plus the header tank fuel is actually applying a forc

e to the valve surface roughly double that of the smaller surface impacted

by the RH fuel.=C2-I did some rough math based on tank volume and pressur

es, etc. and came to the following conclusion: - The major reason this syst

em sort of works is called turbulence!=C2- If you could take off, climb a

nd fly a trip with never a bump of any kind you will be out of gas with a f

ull RH tank. =C2-As you probably noted I have modified the valves to allo

w closing pressure to impact some of the opening surface.=C2- My typical

fuel imbalance is less than 5 lts.=C2- For me this is a hand filing opera

tion (though a CNC genius could probably do it).=C2-=C2- You MUST retai

n a seating ring of the original closing surface.=C2- If you change that

it will never close properly again due to the geometry. =C2-One of the un

modified valve photos shows a Chinese character on a wrench flat.=C2- In

English this reads =9CHINGE=9D and must be at the top.=C2- I

mproper positioning could well be the cause of serious imbalance.=C2-=C2

-Cheers;Walt=C2-=C2-=C2-=C2-=C2-Â

________________________________Â Message 4Â _____________________________________

Time: 09:06:58 PM PST US

From: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Subject: Re: Fw: CJ6 uneven fuel flow

Hi Jon;

Thank you!

I have never seen the wing tip vent installation but assume that was

it=99s purpose. Should work as long as it terminates in a

positive (or neutral) pressure area.

I seem to remember from my misspent youth that Cessna produced a lightly

spring loaded vent valve that was installed in the fuel cap. I have

been intending to

track that down for years!!!Â

We really should have an emergency vent of some type in the CJ. ONE is

not enough!  In the T6/Harvard (and most aircraft) each tank is

separately vented.

Over the years I have seen three T6 fuel tanks where you could touch the

tank bottom from the filler hole due to a plugged vent.

Cheers;

Walt Â

From: JON BLAKE

Sent: Monday, December 07, 2020 12:26 PM

Subject: Re: Fw: CJ6 uneven fuel flow

Good info Walt... many thanks. Â

When I first bought my CJ 15 years ago, I was told to wrap the vent on

the belly with a fine mesh screen to keep the bugs out. I was also told

that the vents going out to each wing tips were installed by Yakity Yaks

to help prevent a bug or other debris from causing fuel starvation. Is

that true? Can you shed any more light on those vents?Â

Jon Blake

Saber369(at)comcast.net (Saber369(at)comcast.net)

On 12/07/2020 12:22 PM Walter Lannon <wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

From: Walter Lannon

Sent: Sunday, December 06, 2020 9:09 PM

To: yaklist(at)matronics.com (yaklist(at)matronics.com)

Subject: CJ6 uneven fuel flow

Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should

respond but since it will be a rather long diatribe I thought the Yak

List might be a better venue.

My aircraft is a 1966 model CJ6a, one of four I imported from China in

1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!)Â It was a 6 year (off and on) 100% restoration

including the fuel system where I found some questionable design

features. During this period (from 1993) I also licensed a few others

and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.

Many people have noted the fuel feeds from the LH tank first. That is

not surprising since the LHÂ vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect

favoring LH flow via the shorter fuel feed line to the header tank. Â

The major design problem rests with the header tank flapper valves.Â

There are three of these valves in the aircraft. One is in the fuel

line from the header tank to the fuel pump. It=99s sole purpose

is to direct fuel

from the emerg. (wobble) pump to the engine fuel pump while preventing

reverse flow back to the header tank. This is the type of function the

valve is designed for and it works perfectly because there is a

distinct difference in pressure on each side.Â

With reference to the attached photos note the diameter of the flapper

as compared to the diameter of the incoming fuel hole. A true

=9Cflapper=9D valve is meant to open (or close) with fuel

flow but pressure, though relatively small, is a factor.  If we start

with equal fuel one flapper will open (probably the LH). In theory as

the pressure from the LH tank and the header tank is reduced at some

point the RH will open and the cycle will repeat.

But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface

impacted by the RH fuel.

I did some rough math based on tank volume and pressures, etc. and

came to the following conclusion: - The major reason this system sort of

works is called turbulence! If you could take off, climb and fly a trip

with never a bump of any kind you will be out of gas with a full RH

tank.

As you probably noted I have modified the valves to allow closing

pressure to impact some of the opening surface. My typical fuel

imbalance is less than 5 lts. For me this is a hand filing operation

(though a CNC genius could probably do it).  You MUST retain a seating

ring of the original closing surface. If you change that it will never

close properly again due to the geometry.

One of the un modified valve photos shows a Chinese character on a

wrench flat. In English this reads =9CHINGE=9D and must be

at the top. Improper positioning could well be the cause of serious

imbalance.

Cheers;

Walt

===========

List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Yak-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

hkgibby(at)yahoo.com

Guest

|

Posted: Tue Dec 08, 2020 11:58 am Post subject: Yak-List Digest: 4 Msgs - 12/07/20 Posted: Tue Dec 08, 2020 11:58 am Post subject: Yak-List Digest: 4 Msgs - 12/07/20 |

|

|

Hi Mark-

I have started the same habit of periodically blowing air through the vent system as I believe some fuel migrates into the line sometimes (despite a check valve and having to go up hill around the loop in the cockpit). Make sure fuel caps are off and have a second person feel for air at each bladder as air is blown into the belly tube. You can also check each cockpit vent control (left and right) as each should shut off and air not felt at the tank as you select off in the cockpit. Simple check that has kept tanks flowing relatively evenly and gives me peace of mind.

Hoot

Sent from my iPhone

| Quote: | On Dec 8, 2020, at 2:34 PM, Walter Lannon <wlannon(at)shaw.ca> wrote:

Hi Mark;

When you âblow through the systemâ are you using shop air? If so at what pressure?

Do you dis-connect the header tank vent line? Applying air press to the header will close both flappers and leave the only pressure relief to the fuel to engine outlet. Not sure if that will provide adequate relief.

Your header tank may have grown a bit larger.

Walt

From: Mark Pennington (pennington.construction.inc.1(at)gmail.com)

Sent: Tuesday, December 08, 2020 3:55 AM

To: yak-list(at)matronics.com (yak-list(at)matronics.com)

Subject: Re: Re: Yak-List Digest: 4 Msgs - 12/07/20

Good Morning Yak List

I fly a CJ6 with the bladders so not stock tank or vent piping.

When I was having this problem I consulted another CJ owner with a bladder system ( you know who you are and thank you) and he pointed out after some photos were sent to him that my tube extending from the bottom of the plane was most likely not long enough to be in the slipstream and apply the pressure to the vent system and the top of the fuel in the tanks. I extended the tube about 3/8" farther down and it cured my tank imbalance. Also, what I do about every third flight or so is I put a hose on the vent tube extending from the bottom of the plane and open one fuel tank at a time and blow through the system and clear the vent system back to the tank. I close that tank and open the other and repeat. Sometimes I can tell I am clearing something from the vent system back into the tank. Most likely fuel. I dont fly straight and level very long when I go out.

I make sure the ball is centered and pay attention to wings level and I rarely come back with a fuel imbalance. I did inspect the flapper valves during one of my condition inspections and made sure they were clean and freely moving but made no modifications to them. I usually refuel after the flight and before I put the plane in the hangar. Usually the tanks are within 1 to 2 gallons of each other... A couple of times, I have come back after a couple of hours of flight time and one tank was down much farther than the other. Before I put the plane away , I put the hose on the vent tube and could tell one tank's vent system was plugged. So the imbalance made sense.

Hope this helps.

Mark

N621CJ

Virus-free. www.avast.com Virus-free. www.avast.com

On Tue, Dec 8, 2020 at 6:20 AM Craig Payne <yakman285(at)gmail.com (yakman285(at)gmail.com)> wrote:

| Quote: | Some years back the popular fix was to file some notches in the flapper valves. To me that seemed to defeat the purpose. Using a little MMO in the fuel made me feel better anyway.

Craig Payne

On Tue, Dec 8, 2020 at 2:53 AM Yak-List Digest Server <yak-list(at)matronics.com (yak-list(at)matronics.com)> wrote:

| Quote: | *

=========================

Online Versions of Today's List Digest Archive

=========================

Today's complete Yak-List Digest can also be found in either of the

two Web Links listed below. The .html file includes the Digest formatted

in HTML for viewing with a web browser and features Hyperlinked Indexes

and Message Navigation. The .txt file includes the plain ASCII version

of the Yak-List Digest and can be viewed with a generic text editor

such as Notepad or with a web browser.

HTML Version:

http://www.matronics.com/digest/digestview.php?Style=82701&View=html&Chapter=2020-12-07&Archive=Yak

Text Version:

http://www.matronics.com/digest/digestview.php?Style=82701&View=txt&Chapter=2020-12-07&Archive=Yak

=======================

EMail Version of Today's List Digest Archive

=======================

----------------------------------------------------------

Yak-List Digest Archive

---

Total Messages Posted Mon 12/07/20: 4

----------------------------------------------------------

Today's Message Index:

----------------------

1. 10:24 AM - Fw: CJ6 uneven fuel flow (Walter Lannon)

2. 12:28 PM - Re: Fw: CJ6 uneven fuel flow (JON BLAKE)

3. 01:30 PM - Re: Fw: CJ6 uneven fuel flow (Larry Pine)

4. 09:06 PM - Re: Fw: CJ6 uneven fuel flow (Walter Lannon)

________________________________ Message 1 _____________________________________

Time: 10:24:05 AM PST US

From: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Subject: Fw: CJ6 uneven fuel flow

From: Walter Lannon

Sent: Sunday, December 06, 2020 9:09 PM

Subject: CJ6 uneven fuel flow

Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should

respond but since it will be a rather long diatribe I thought the Yak

List might be a better venue.

My aircraft is a 1966 model CJ6a, one of four I imported from China in

1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!) It was a 6 year (off and on) 100% restoration

including the fuel system where I found some questionable design

features. During this period (from 1993) I also licensed a few others

and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.

Many people have noted the fuel feeds from the LH tank first. That is

not surprising since the LH vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect

favoring LH flow via the shorter fuel feed line to the header tank.

The major design problem rests with the header tank flapper valves.

There are three of these valves in the aircraft. One is in the fuel

line from the header tank to the fuel pump. It=99s sole purpose

is to direct fuel

from the emerg. (wobble) pump to the engine fuel pump while preventing

reverse flow back to the header tank. This is the type of function the

valve is designed for and it works perfectly because there is a

distinct difference in pressure on each side.

With reference to the attached photos note the diameter of the flapper

as compared to the diameter of the incoming fuel hole. A true

=9Cflapper=9D valve is meant to open (or close) with fuel

flow but pressure, though relatively small, is a factor. If we start

with equal fuel one flapper will open (probably the LH). In theory as

the pressure from the LH tank and the header tank is reduced at some

point the RH will open and the cycle will repeat.

But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface

impacted by the RH fuel.

I did some rough math based on tank volume and pressures, etc. and came

to the following conclusion: - The major reason this system sort of

works is called turbulence! If you could take off, climb and fly a trip

with never a bump of any kind you will be out of gas with a full RH

tank.

As you probably noted I have modified the valves to allow closing

pressure to impact some of the opening surface. My typical fuel

imbalance is less than 5 lts. For me this is a hand filing operation

(though a CNC genius could probably do it). You MUST retain a seating

ring of the original closing surface. If you change that it will never

close properly again due to the geometry.

One of the un modified valve photos shows a Chinese character on a

wrench flat. In English this reads =9CHINGE=9D and must be

at the top. Improper positioning could well be the cause of serious

imbalance.

Cheers;

Walt

________________________________ Message 2 _____________________________________

Time: 12:28:05 PM PST US

From: JON BLAKE <saber369(at)comcast.net (saber369(at)comcast.net)>

Subject: Re: Yak-List: Fw: CJ6 uneven fuel flow

Good info Walt... many thanks.

When I first bought my CJ 15 years ago, I was told to wrap the vent on the

belly with a fine mesh screen to keep the bugs out. I was also told that t

he vents going out to each wing tips were installed by Yakity Yaks to help

prevent a bug or other debris from causing fuel starvation. Is that true?

Can you shed any more light on those vents?

Jon Blake

Saber369(at)comcast.net (Saber369(at)comcast.net)

spond but since it will be a rather long diatribe I thought the Yak List mi

ght be a better venue.

| Quote: |

My aircraft is a 1966 model CJ6a, one of four I imported from China i

n 1993. Did not start my own restoration until after selling my Harvard 4

|

in 2006 (after 30 years!) It was a 6 year (off and on) 100% restoration in

cluding the fuel system where I found some questionable design features. D

uring this period (from 1993) I also licensed a few others and found it was

necessary to do a hot soap and water flush of the fuel vent system to remo

ve bug debris.

| Quote: |

Many people have noted the fuel feeds from the LH tank first. That i

s not surprising since the LH vent system is much shorter than the RH and

|

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

| Quote: | tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect favor

|

ing LH flow via the shorter fuel feed line to the header tank.

| Quote: |

The major design problem rests with the header tank flapper valves.

There are three of these valves in the aircraft. One is in the fuel line f

|

rom the header tank to the fuel pump. It=99s sole purpose is to dire

ct fuel

| Quote: | from the emerg. (wobble) pump to the engine fuel pump while preventin

g reverse flow back to the header tank. This is the type of function the v

|

alve is designed for and it works perfectly because there is a

| Quote: | distinct difference in pressure on each side.

With reference to the attached photos note the diameter of the flappe

r as compared to the diameter of the incoming fuel hole. A true =9Cf

|

lapper=9D valve is meant to open (or close) with fuel flow but pressu

re, though relatively small, is a factor. If we start with equal fuel one

flapper will open (probably the LH). In theory as the pressure from the L

H tank and the header tank is reduced at some point the RH will open and th

e cycle will repeat.

| Quote: | But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface impa

|

cted by the RH fuel.

| Quote: |

I did some rough math based on tank volume and pressures, etc. and ca

me to the following conclusion: - The major reason this system sort of work

|

s is called turbulence! If you could take off, climb and fly a trip with n

ever a bump of any kind you will be out of gas with a full RH tank.

| Quote: |

As you probably noted I have modified the valves to allow closing pre

ssure to impact some of the opening surface. My typical fuel imbalance is

|

less than 5 lts. For me this is a hand filing operation (though a CNC geni

us could probably do it). You MUST retain a seating ring of the original

closing surface. If you change that it will never close properly again due

to the geometry.

| Quote: |

One of the un modified valve photos shows a Chinese character on a wr

ench flat. In English this reads =9CHINGE=9D and must be at th

|

e top. Improper positioning could well be the cause of serious imbalance.

________________________________ Message 3 _____________________________________

Time: 01:30:00 PM PST US

From: Larry Pine <threein60(at)yahoo.com (threein60(at)yahoo.com)>

Subject: Re: Fw: CJ6 uneven fuel flow

Great write-up on this. Let me add a little learned knowledge to this discu

ssion. I have no issues with what Walt stated but a few years ago I had fue

l starvation while on the ground. I could start the engine on my electrical

boost pump but the minute I shut it off, the engine would die. I checked f

uel levels, I removed and cleaned the fuel strainer and checked for flow, s

till nothing. Only when I removed the flapper valve under the floor, the on

e that feeds the wobble pump, I found the hinge in this flapper was worn an

d could rotate to a place where it would get stuck closed. This was the fir

st I have ever hear of this happening. I cleaned and lightly refaced both t

he flapper and flapper seat. I then replaced the worn hinge pivot rod with

a new brass one. I have plans to take apart this valve again during this mo

nths annual and see if these is any wear taking place on the hinge rod. Luc

ky I found this on the ground but confident had this happened in flight, my

electric driven pump would have supplied enough fuel to get me back safely

. Still some thing that should be examined.

I have bladder tanks so my vents are extended to their respective wing tips

with a separate vent for the header tank. I find that I tend to fly more p

ressure on my left rudder because my knee board is on my right and lifting

my right knee a little makes writing easier. This tends to cause a noticeab

le fuel difference over a 2 hour period. I know, bad pilot bad. Very early

on before I had my bladder tanks installed, I had to do an emergency divert

because my one tank was almost dry and the opposite tank wasn't moving the

needle yet. Only after landing I noticed the needle move. Constant fuel ma

nagement has become the norm. I optioned to not install the vent shut off v

alues after and incident I had with another RPAer. This pilot closed one of

his vents to overcome the fuel flow difference and forgot to open the vent

again. On roll out with the engine pulled to ideal, the engine died on the

runway. It would start but than die again. When we got it to parking, we n

oticed one bladder tank was sucked flat and dry..... The same side with the

closed vent. Human factors are human factors! Unless you design a system t

o incorporate some warning when the pressure builds or the vent is closed i

ndication, this only complicates memory items that needs to be attended and

eventually can lead to failures.

Larry Pine On Monday, December 7, 2020, 10:48:19 AM PST, Walter Lannon

<wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

=C2-=C2-From: Walter Lannon Sent: Sunday, December 06, 2020 9:09 PMTo:

yaklist(at)matronics.com (yaklist(at)matronics.com) Subject: CJ6 uneven fuel flow=C2-Currently there i

s a lot of interest in the above subject on the Red Star site.=C2- Since

I have some experience in this area I thought I should respond but since it

will be a rather long diatribe I thought the Yak List might be a better ve

nue.=C2-My aircraft is a 1966 model CJ6a, one of four I imported from Chi

na in 1993.=C2- Did not start my own restoration until after selling my H

arvard 4 in 2006 (after 30 years!)=C2- It was a 6 year (off and on) 100%

restoration including the fuel system where I found some questionable desig

n features.=C2- During this period (from 1993) I also licensed a few othe

rs and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.=C2-Many people have noted the fuel feed

s from the LH tank first.=C2- That is not surprising since the LH=C2- v

ent system is much shorter than the RH and the tube is 8 mm (6 mm ID) for b

oth.=C2- Not a huge problem as long as the tubing is internally clean and

totally free of any damage that could restrict air flow. This is critical!

=C2- There is also some minor effect favoring LH flow via the shorter fue

l feed line to the header tank.=C2-=C2-=C2- =C2-The major design pr

oblem rests with the header tank flapper valves.=C2- There are three of t

hese valves in the aircraft.=C2- One is in the fuel line from the header

tank to the fuel pump.=C2- It=99s sole purpose is to direct fuelfro

m the emerg. (wobble) pump to the engine fuel pump while preventing reverse

flow back to the header tank.=C2- This is the type of function the valve

is designed for and it works perfectly because there is a distinct differe

nce in pressure on each side.=C2- =C2-With reference to the attached ph

otos note the diameter of the flapper as compared to the diameter of the in

coming fuel hole.=C2- A true =9Cflapper=9D valve is meant to

open (or close) with fuel flow but pressure, though relatively small, is a

factor.=C2-=C2- If we start with equal fuel one flapper will open (prob

ably the LH).=C2- In theory as the pressure from the LH tank and the head

er tank is reduced at some point the RH will open and the cycle will repeat

.But, in fact, the LH plus the header tank fuel is actually applying a forc

e to the valve surface roughly double that of the smaller surface impacted

by the RH fuel.=C2-I did some rough math based on tank volume and pressur

es, etc. and came to the following conclusion: - The major reason this syst

em sort of works is called turbulence!=C2- If you could take off, climb a

nd fly a trip with never a bump of any kind you will be out of gas with a f

ull RH tank. =C2-As you probably noted I have modified the valves to allo

w closing pressure to impact some of the opening surface.=C2- My typical

fuel imbalance is less than 5 lts.=C2- For me this is a hand filing opera

tion (though a CNC genius could probably do it).=C2-=C2- You MUST retai

n a seating ring of the original closing surface.=C2- If you change that

it will never close properly again due to the geometry. =C2-One of the un

modified valve photos shows a Chinese character on a wrench flat.=C2- In

English this reads =9CHINGE=9D and must be at the top.=C2- I

mproper positioning could well be the cause of serious imbalance.=C2-=C2

-Cheers;Walt=C2-=C2-=C2-=C2-=C2-

________________________________ Message 4 _____________________________________

Time: 09:06:58 PM PST US

From: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Subject: Re: Fw: CJ6 uneven fuel flow

Hi Jon;

Thank you!

I have never seen the wing tip vent installation but assume that was

it=99s purpose. Should work as long as it terminates in a

positive (or neutral) pressure area.

I seem to remember from my misspent youth that Cessna produced a lightly

spring loaded vent valve that was installed in the fuel cap. I have

been intending to

track that down for years!!!

We really should have an emergency vent of some type in the CJ. ONE is

not enough! In the T6/Harvard (and most aircraft) each tank is

separately vented.

Over the years I have seen three T6 fuel tanks where you could touch the

tank bottom from the filler hole due to a plugged vent.

Cheers;

Walt

From: JON BLAKE

Sent: Monday, December 07, 2020 12:26 PM

Subject: Re: Fw: CJ6 uneven fuel flow

Good info Walt... many thanks.

When I first bought my CJ 15 years ago, I was told to wrap the vent on

the belly with a fine mesh screen to keep the bugs out. I was also told

that the vents going out to each wing tips were installed by Yakity Yaks

to help prevent a bug or other debris from causing fuel starvation. Is

that true? Can you shed any more light on those vents?

Jon Blake

Saber369(at)comcast.net (Saber369(at)comcast.net)

On 12/07/2020 12:22 PM Walter Lannon <wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

From: Walter Lannon

Sent: Sunday, December 06, 2020 9:09 PM

To: yaklist(at)matronics.com (yaklist(at)matronics.com)

Subject: CJ6 uneven fuel flow

Currently there is a lot of interest in the above subject on the Red

Star site. Since I have some experience in this area I thought I should

respond but since it will be a rather long diatribe I thought the Yak

List might be a better venue.

My aircraft is a 1966 model CJ6a, one of four I imported from China in

1993. Did not start my own restoration until after selling my Harvard 4

in 2006 (after 30 years!) It was a 6 year (off and on) 100% restoration

including the fuel system where I found some questionable design

features. During this period (from 1993) I also licensed a few others

and found it was necessary to do a hot soap and water flush of the fuel

vent system to remove bug debris.

Many people have noted the fuel feeds from the LH tank first. That is

not surprising since the LH vent system is much shorter than the RH and

the tube is 8 mm (6 mm ID) for both. Not a huge problem as long as the

tubing is internally clean and totally free of any damage that could

restrict air flow. This is critical! There is also some minor effect

favoring LH flow via the shorter fuel feed line to the header tank.

The major design problem rests with the header tank flapper valves.

There are three of these valves in the aircraft. One is in the fuel

line from the header tank to the fuel pump. It=99s sole purpose

is to direct fuel

from the emerg. (wobble) pump to the engine fuel pump while preventing

reverse flow back to the header tank. This is the type of function the

valve is designed for and it works perfectly because there is a

distinct difference in pressure on each side.

With reference to the attached photos note the diameter of the flapper

as compared to the diameter of the incoming fuel hole. A true

=9Cflapper=9D valve is meant to open (or close) with fuel

flow but pressure, though relatively small, is a factor. If we start

with equal fuel one flapper will open (probably the LH). In theory as

the pressure from the LH tank and the header tank is reduced at some

point the RH will open and the cycle will repeat.

But, in fact, the LH plus the header tank fuel is actually applying a

force to the valve surface roughly double that of the smaller surface

impacted by the RH fuel.

I did some rough math based on tank volume and pressures, etc. and

came to the following conclusion: - The major reason this system sort of

works is called turbulence! If you could take off, climb and fly a trip

with never a bump of any kind you will be out of gas with a full RH

tank.

As you probably noted I have modified the valves to allow closing

pressure to impact some of the opening surface. My typical fuel

imbalance is less than 5 lts. For me this is a hand filing operation

(though a CNC genius could probably do it). You MUST retain a seating

ring of the original closing surface. If you change that it will never

close properly again due to the geometry.

One of the un modified valve photos shows a Chinese character on a

wrench flat. In English this reads =9CHINGE=9D and must be

at the top. Improper positioning could well be the cause of serious

imbalance.

Cheers;

Walt

===========

List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Yak-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

Virus-free. www.avast.com Virus-free. www.avast.com

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

pennington.construction.i

Guest

|

Posted: Tue Dec 08, 2020 1:23 pm Post subject: Yak-List Digest: 4 Msgs - 12/07/20 Posted: Tue Dec 08, 2020 1:23 pm Post subject: Yak-List Digest: 4 Msgs - 12/07/20 |

|

|

Hey Walt.

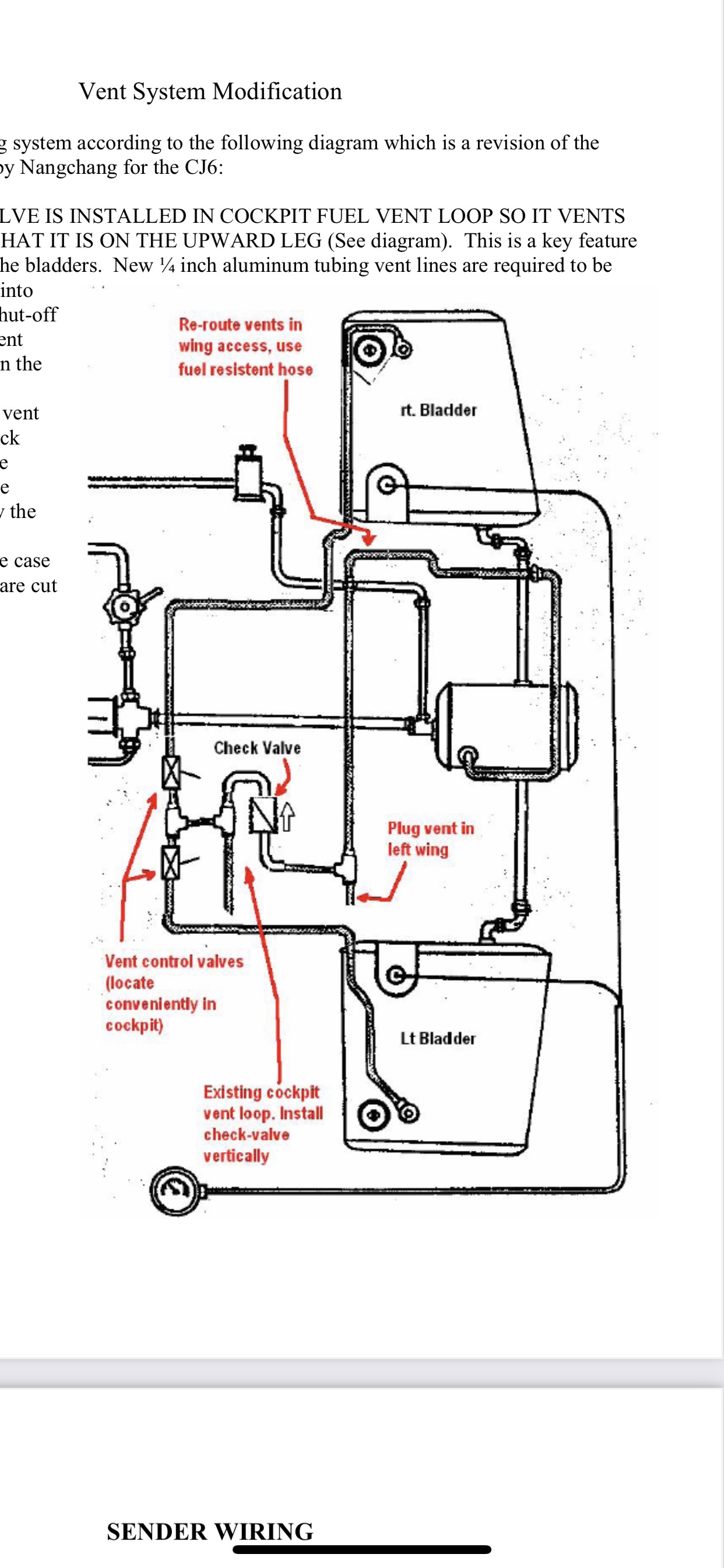

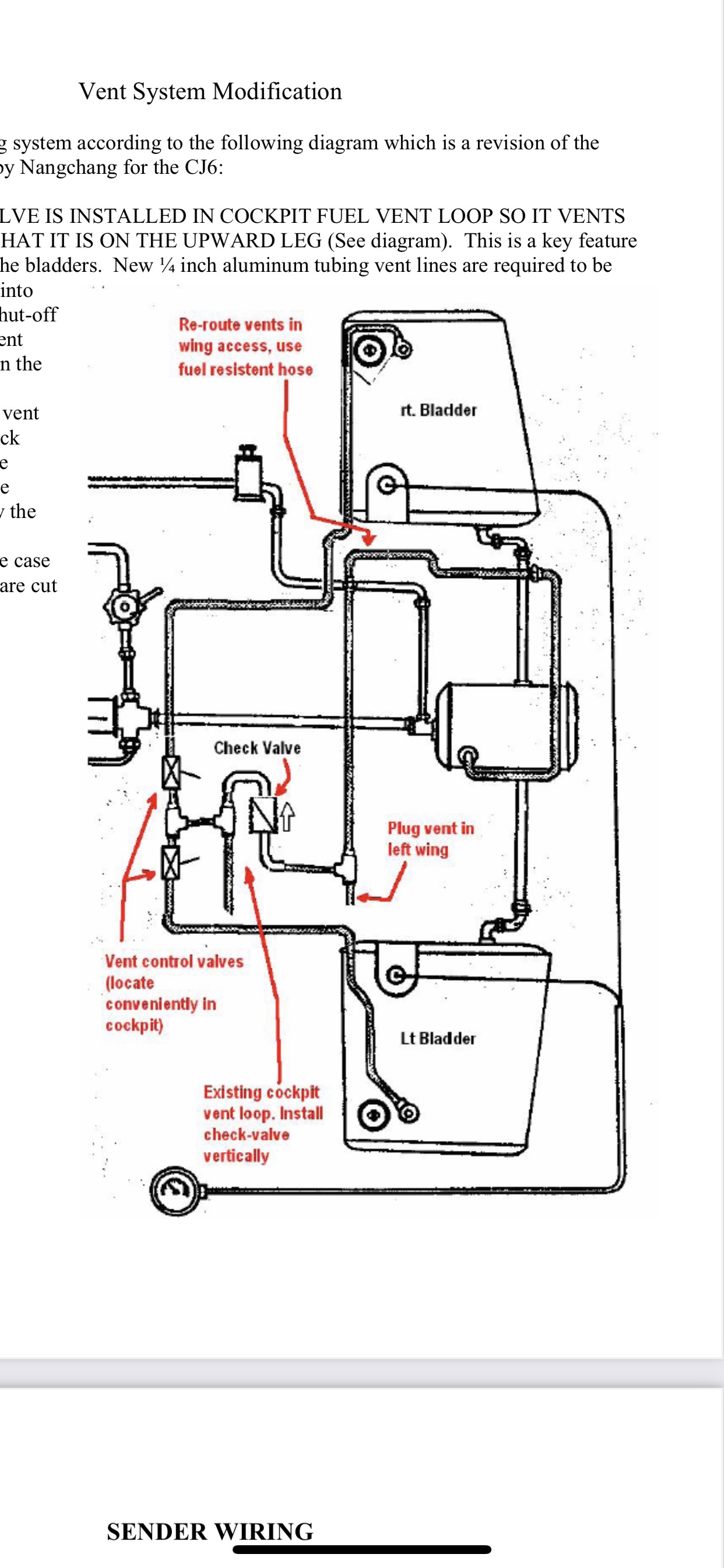

Hope everything is going well on your end. I dont use shop pressure. I use whatever pressure is in my lungs. I blow into the hose like you're blowing up a balloon.  When you install the bladder system you put a check valve in the vent loop behind the pilots left shoulder. That check valve keeps air from getting to the header tank but allows fuel to escape if need be. So when you leave one bladder open and blow into the vent on the bottom of the plane you're only clearing the line to that tank back to the tank and the check valve keeps the air pressure off of the header tank. The check valve is mounted vertically with the ball closing the check valve due to gravity and or pressure coming into the vent system through the tube out of the bottom of the plane when it is moving.

Then I close the first bladder and then open the other one and repeat.  The system was in when I got the plane so I have no experience with the stock system at all.  Nor did I install this one. I did verify my system is installed as the attached diagram shows. When Gil was with us he explained the vent system was put in like this to make sure the bladders would empty completely. Â

I attached the diagram for installation of the check valve as part of the bladder system for the CJ.Â

Mark

N621CJ

Â

On Tue, Dec 8, 2020 at 2:26 PM Walter Lannon <wlannon(at)shaw.ca (wlannon(at)shaw.ca)> wrote:

| Quote: | Hi Mark;

Â

When you âblow through the systemâ are you using shop air? If so at what pressure?

Â

Do you dis-connect the header tank vent line?  Applying air press to the header will close both flappers and leave the only pressure relief to the fuel to engine outlet. Not sure if that will provide adequate relief.

Your header tank may have grown a bit larger.

Â

Walt

Â

From: Mark Pennington (pennington.construction.inc.1(at)gmail.com)

Sent: Tuesday, December 08, 2020 3:55 AM

To: yak-list(at)matronics.com (yak-list(at)matronics.com)

Subject: Re: Re: Yak-List Digest: 4 Msgs - 12/07/20

Â

Good Morning Yak List Â

I fly a CJ6 with the bladders so not stock tank or vent piping.

Â

When I was having this problem I consulted another CJ owner with a bladder system ( you know who you are and thank you) and he pointed out after some photos were sent to him that my tube extending from the bottom of the plane was most likely not long enough to be in the slipstream and apply the pressure to the vent system and the top of the fuel in the tanks. I extended the tube about 3/8" farther down and it cured my tank imbalance. Also, what I do about every third flight or so is I put a hose on the vent tube extending from the bottom of the plane and open one fuel tank at a time and blow through the system and clear the vent system back to the tank. I close that tank and open the other and repeat. Sometimes I can tell I am clearing something from the vent system back into the tank. Most likely fuel. I dont fly straight and level very long when I go out. Â

Â

I make sure the ball is centered and pay attention to wings level and I rarely come back with a fuel imbalance. I did inspect the flapper valves during one of my condition inspections and made sure they were clean and freely moving but made no modifications to them.  I usually refuel after the flight and before I put the plane in the hangar. Usually the tanks are within 1 to 2 gallons of each other... A couple of times, I have come back after a couple of hours of flight time and one tank was down much farther than the other. Before I put the plane away , I put the hose on the vent tube and could tell one tank's vent system was plugged. So the imbalance made sense.

Â

Hope this helps.Â

Â

Mark

N621CJ

Â

Â

Â

Â

Virus-free. www.avast.com Virus-free. www.avast.com

Â

On Tue, Dec 8, 2020 at 6:20 AM Craig Payne <yakman285(at)gmail.com (yakman285(at)gmail.com)> wrote:

| Quote: | Some years back the popular fix was to file some notches in the flapper valves. To me that seemed to defeat the purpose. Using a little MMO in the fuel made me feel better anyway.

Â

Craig Payne

Â

On Tue, Dec 8, 2020 at 2:53 AM Yak-List Digest Server <yak-list(at)matronics.com (yak-list(at)matronics.com)> wrote:

| Quote: | *

=========================