|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

bsvantho

Joined: 16 Apr 2018

Posts: 3

|

Posted: Fri Apr 20, 2018 5:52 am Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 5:52 am Post subject: Z-12 contactor failure |

|

|

I know it is not a likely case, but I have experienced a contactor failure on a production plane in flight. It ended up that the root cause was a defective master switch - but the result was the same. Because there was no endurance bus alternate feed, it was a full electrical shutdown, in IMC no less!

I would like to know if there is a practical way to protect for contactor failure ( other than battery only operation ) with the Z-12 design. It would be nice to have a second path to the battery from aux alternator to ensure stable power if the master does fail. The appeal to me of having an aux alternator is to be able to continue flight on one alternator. This is only possible if either a battery connection is maintained always or it is a guarantee the alternator will provide stable power without a battery connection.

The Z-13/8 uses a relay with the SD-8 alternator to connect directly to battery. Is this design practical or even advisable with the SD-20 alternator? With Z-13/8 the aux alternator will provide power to battery bus and E-BUS if contactor fails.

Thoughts?

Thanks,

-Brendon

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Apr 20, 2018 8:02 am Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 8:02 am Post subject: Z-12 contactor failure |

|

|

Brendon:

If the Master Switch failed why reinvent the wheel? Â

Since this was a certified plane you are forced to work with the design of the time.

What I have found is 99.982% of certified plane owners and A&P's, NEVER address the Master Switch during Annual.

It should be addressed every Annual and it is very easy to do:

1 - Spray the heck out of it with Contact Cleaner.

2 - Cycle the switch a couple of dozen times.

3 - Spray it with WD-40. Â

Side Note:Â This also goes for the micro-switch in the Stall Warning System.

On Experimental Aircraft you have a HUGE ADVANTAGE...

Use a Heavy Duty Master Switch and a Separate Heavy Duty Alternator Switch.

I use DPST switches and tie BOTH sides together. This DOUBLES the physical as well as the electrical rating of the switch.

Want to go extra fancy? Look for switches that are Sliver Plated.

You can also use switches that have a built in Dust/Moisture shield. OR... Install the dust/Moisture shield over the Toggle Lever.

Side Note:Â On certified planes with the standard split Master/Alt Switch, there are four (4) failure points:

1 - The Physical snap action of the switch.

2 - The Electrical contacts of the switch.

3 - Fast-On tabs on the back of the switch.

4 - The Physical MOUNTING of the switch.  There is a snap in bezel that holds the switch into the panel.Â

This bezel fails as the ears either break off or loose their spring action.

Then the switch vibrates forward and shorts out to the aluminum panel.

The cure is to use two (2) sheet metal round head screws on either side to hold the bezel in place.

If the switch vibrates out it will short out and take your Master/Alt switch and Starter Relay out of the circuit.

If you are airborne - You loose even the ability to go to Battery Back-up.

Or do an in-flight re-start.

Scary!

Barry

On Fri, Apr 20, 2018 at 9:52 AM, bsvantho <bsvantho(at)gmail.com (bsvantho(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "bsvantho" <bsvantho(at)gmail.com (bsvantho(at)gmail.com)>

I know it is not a likely case, but I have experienced a contactor failure on a production plane in flight.  It ended up that the root cause was a defective master switch - but the result was the same.  Because there was no endurance bus alternate feed, it was a full electrical shutdown, in IMC no less!

I would like to know if there is a practical way to protect for contactor failure ( other than battery only operation ) with the Z-12 design. It would be nice to have a second path to the battery from aux alternator to ensure stable power if the master does fail. The appeal to me of having an aux alternator is to be able to continue flight on one alternator. This is only possible if either a battery connection is maintained always or it is a guarantee the alternator will provide stable power without a battery connection. Â

The Z-13/8 uses a relay with the SD-8 alternator to connect directly to battery.  Is this design practical or even advisable with the SD-20 alternator?  With Z-13/8 the aux alternator will provide power to battery bus and E-BUS if contactor fails. Â

Thoughts?

Thanks,

-Brendon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=479453#479453

====================================

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bob.verwey(at)gmail.com

Guest

|

Posted: Fri Apr 20, 2018 8:27 am Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 8:27 am Post subject: Z-12 contactor failure |

|

|

Barry I can't see how applying a lubricant like WD40 can be advantageous to the contacts on the switch...surely there will be burning volatiles or lube which would affect the service or life of the part? On the moving parts yes but I don't know of a way to differentiate with a spray can.

On Fri, 20 Apr 2018, 6:13 PM FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: | Brendon:

If the Master Switch failed why reinvent the wheel? Â

Since this was a certified plane you are forced to work with the design of the time.

What I have found is 99.982% of certified plane owners and A&P's, NEVER address the Master Switch during Annual.

It should be addressed every Annual and it is very easy to do:

1 - Spray the heck out of it with Contact Cleaner.

2 - Cycle the switch a couple of dozen times.

3 - Spray it with WD-40. Â

Side Note:Â This also goes for the micro-switch in the Stall Warning System.

On Experimental Aircraft you have a HUGE ADVANTAGE...

Use a Heavy Duty Master Switch and a Separate Heavy Duty Alternator Switch.

I use DPST switches and tie BOTH sides together. This DOUBLES the physical as well as the electrical rating of the switch.

Want to go extra fancy? Look for switches that are Sliver Plated.

You can also use switches that have a built in Dust/Moisture shield. OR... Install the dust/Moisture shield over the Toggle Lever.

Side Note:Â On certified planes with the standard split Master/Alt Switch, there are four (4) failure points:

1 - The Physical snap action of the switch.

2 - The Electrical contacts of the switch.

3 - Fast-On tabs on the back of the switch.

4 - The Physical MOUNTING of the switch.  There is a snap in bezel that holds the switch into the panel.Â

This bezel fails as the ears either break off or loose their spring action.

Then the switch vibrates forward and shorts out to the aluminum panel.

The cure is to use two (2) sheet metal round head screws on either side to hold the bezel in place.

If the switch vibrates out it will short out and take your Master/Alt switch and Starter Relay out of the circuit.

If you are airborne - You loose even the ability to go to Battery Back-up.

Or do an in-flight re-start.

Scary!

Barry

On Fri, Apr 20, 2018 at 9:52 AM, bsvantho <bsvantho(at)gmail.com (bsvantho(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "bsvantho" <bsvantho(at)gmail.com (bsvantho(at)gmail.com)>

I know it is not a likely case, but I have experienced a contactor failure on a production plane in flight.  It ended up that the root cause was a defective master switch - but the result was the same.  Because there was no endurance bus alternate feed, it was a full electrical shutdown, in IMC no less!

I would like to know if there is a practical way to protect for contactor failure ( other than battery only operation ) with the Z-12 design. It would be nice to have a second path to the battery from aux alternator to ensure stable power if the master does fail. The appeal to me of having an aux alternator is to be able to continue flight on one alternator. This is only possible if either a battery connection is maintained always or it is a guarantee the alternator will provide stable power without a battery connection. Â

The Z-13/8 uses a relay with the SD-8 alternator to connect directly to battery.  Is this design practical or even advisable with the SD-20 alternator?  With Z-13/8 the aux alternator will provide power to battery bus and E-BUS if contactor fails. Â

Thoughts?

Thanks,

-Brendon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=479453#479453

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Apr 20, 2018 9:43 am Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 9:43 am Post subject: Z-12 contactor failure |

|

|

Bob:

Yup! There are all sorts of 'possible' possibilities, all without proof, but it DOES WORK!

Many of our aircraft are 40+ years old. The original lubricants in the switches have long disappeared.

They are NOT sealed switches.

What has worked for many years are now failing. Just look Brandon's post.

And, when it comes to the Stall Warning micro switch - Replacement with NEW is $1200+ used, about $600 to $700.

All this can be prevented with a can of WD-40!

Not needed on sealed DPST Toggle Switches. AND they are NOT 40+ years old.

Barry

On Fri, Apr 20, 2018 at 12:25 PM, Bob Verwey <bob.verwey(at)gmail.com (bob.verwey(at)gmail.com)> wrote:

| Quote: | Barry I can't see how applying a lubricant like WD40 can be advantageous to the contacts on the switch...surely there will be burning volatiles or lube which would affect the service or life of the part? On the moving parts yes but I don't know of a way to differentiate with a spray can.

On Fri, 20 Apr 2018, 6:13 PM FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: | Brendon:

If the Master Switch failed why reinvent the wheel? Â

Since this was a certified plane you are forced to work with the design of the time.

What I have found is 99.982% of certified plane owners and A&P's, NEVER address the Master Switch during Annual.

It should be addressed every Annual and it is very easy to do:

1 - Spray the heck out of it with Contact Cleaner.

2 - Cycle the switch a couple of dozen times.

3 - Spray it with WD-40. Â

Side Note:Â This also goes for the micro-switch in the Stall Warning System.

On Experimental Aircraft you have a HUGE ADVANTAGE...

Use a Heavy Duty Master Switch and a Separate Heavy Duty Alternator Switch.

I use DPST switches and tie BOTH sides together. This DOUBLES the physical as well as the electrical rating of the switch.

Want to go extra fancy? Look for switches that are Sliver Plated.

You can also use switches that have a built in Dust/Moisture shield. OR... Install the dust/Moisture shield over the Toggle Lever.

Side Note:Â On certified planes with the standard split Master/Alt Switch, there are four (4) failure points:

1 - The Physical snap action of the switch.

2 - The Electrical contacts of the switch.

3 - Fast-On tabs on the back of the switch.

4 - The Physical MOUNTING of the switch.  There is a snap in bezel that holds the switch into the panel.Â

This bezel fails as the ears either break off or loose their spring action.

Then the switch vibrates forward and shorts out to the aluminum panel.

The cure is to use two (2) sheet metal round head screws on either side to hold the bezel in place.

If the switch vibrates out it will short out and take your Master/Alt switch and Starter Relay out of the circuit.

If you are airborne - You loose even the ability to go to Battery Back-up.

Or do an in-flight re-start.

Scary!

Barry

On Fri, Apr 20, 2018 at 9:52 AM, bsvantho <bsvantho(at)gmail.com (bsvantho(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "bsvantho" <bsvantho(at)gmail.com (bsvantho(at)gmail.com)>

I know it is not a likely case, but I have experienced a contactor failure on a production plane in flight.  It ended up that the root cause was a defective master switch - but the result was the same.  Because there was no endurance bus alternate feed, it was a full electrical shutdown, in IMC no less!

I would like to know if there is a practical way to protect for contactor failure ( other than battery only operation ) with the Z-12 design. It would be nice to have a second path to the battery from aux alternator to ensure stable power if the master does fail. The appeal to me of having an aux alternator is to be able to continue flight on one alternator. This is only possible if either a battery connection is maintained always or it is a guarantee the alternator will provide stable power without a battery connection. Â

The Z-13/8 uses a relay with the SD-8 alternator to connect directly to battery.  Is this design practical or even advisable with the SD-20 alternator?  With Z-13/8 the aux alternator will provide power to battery bus and E-BUS if contactor fails. Â

Thoughts?

Thanks,

-Brendon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=479453#479453

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Fri Apr 20, 2018 9:53 am Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 9:53 am Post subject: Z-12 contactor failure |

|

|

Calling WD40 "a lubricant" is like calling a 1969 Chateauneuf âa liquidâ!

On Apr 20, 2018, at 1:41 PM, FLYaDIVE <flyadive(at)gmail.com> wrote:

Bob:

Yup! There are all sorts of 'possible' possibilities, all without proof, but it DOES WORK!

Many of our aircraft are 40+ years old. The original lubricants in the switches have long disappeared.

They are NOT sealed switches.

What has worked for many years are now failing. Just look Brandon's post.

And, when it comes to the Stall Warning micro switch - Replacement with NEW is $1200+ used, about $600 to $700.

All this can be prevented with a can of WD-40!

Not needed on sealed DPST Toggle Switches. AND they are NOT 40+ years old.

Barry

On Fri, Apr 20, 2018 at 12:25 PM, Bob Verwey <bob.verwey(at)gmail.com> wrote:

Barry I can't see how applying a lubricant like WD40 can be advantageous to the contacts on the switch...surely there will be burning volatiles or lube which would affect the service or life of the part? On the moving parts yes but I don't know of a way to differentiate with a spray can.

On Fri, 20 Apr 2018, 6:13 PM FLYaDIVE <flyadive(at)gmail.com> wrote:

Brendon:

If the Master Switch failed why reinvent the wheel?

Since this was a certified plane you are forced to work with the design of the time.

What I have found is 99.982% of certified plane owners and A&P's, NEVER address the Master Switch during Annual.

It should be addressed every Annual and it is very easy to do:

1 - Spray the heck out of it with Contact Cleaner.

2 - Cycle the switch a couple of dozen times.

3 - Spray it with WD-40.

Side Note: This also goes for the micro-switch in the Stall Warning System.

On Experimental Aircraft you have a HUGE ADVANTAGE...

Use a Heavy Duty Master Switch and a Separate Heavy Duty Alternator Switch.

I use DPST switches and tie BOTH sides together. This DOUBLES the physical as well as the electrical rating of the switch.

Want to go extra fancy? Look for switches that are Sliver Plated.

You can also use switches that have a built in Dust/Moisture shield. OR... Install the dust/Moisture shield over the Toggle Lever.

Side Note: On certified planes with the standard split Master/Alt Switch, there are four (4) failure points:

1 - The Physical snap action of the switch.

2 - The Electrical contacts of the switch.

3 - Fast-On tabs on the back of the switch.

4 - The Physical MOUNTING of the switch. There is a snap in bezel that holds the switch into the panel.

This bezel fails as the ears either break off or loose their spring action.

Then the switch vibrates forward and shorts out to the aluminum panel.

The cure is to use two (2) sheet metal round head screws on either side to hold the bezel in place.

If the switch vibrates out it will short out and take your Master/Alt switch and Starter Relay out of the circuit.

If you are airborne - You loose even the ability to go to Battery Back-up.

Or do an in-flight re-start.

Scary!

Barry

On Fri, Apr 20, 2018 at 9:52 AM, bsvantho <bsvantho(at)gmail.com> wrote:

I know it is not a likely case, but I have experienced a contactor failure on a production plane in flight. It ended up that the root cause was a defective master switch - but the result was the same. Because there was no endurance bus alternate feed, it was a full electrical shutdown, in IMC no less!

I would like to know if there is a practical way to protect for contactor failure ( other than battery only operation ) with the Z-12 design. It would be nice to have a second path to the battery from aux alternator to ensure stable power if the master does fail. The appeal to me of having an aux alternator is to be able to continue flight on one alternator. This is only possible if either a battery connection is maintained always or it is a guarantee the alternator will provide stable power without a battery connection.

The Z-13/8 uses a relay with the SD-8 alternator to connect directly to battery. Is this design practical or even advisable with the SD-20 alternator? With Z-13/8 the aux alternator will provide power to battery bus and E-BUS if contactor fails.

Thoughts?

Thanks,

-Brendon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=479453#479453

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Apr 20, 2018 10:38 am Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 10:38 am Post subject: Z-12 contactor failure |

|

|

Not calling it a lubricant is proof you consumed too much 1969 Chateauneuf.

I guess you don't call soapstone a lubricant either!

On Fri, Apr 20, 2018 at 1:52 PM, Alec Myers <alec(at)alecmyers.com> wrote:

[quote]

Calling WD40 "a lubricant" is like calling a 1969 Chateauneuf âa liquidâ!

On Apr 20, 2018, at 1:41 PM, FLYaDIVE <flyadive(at)gmail.com> wrote:

Bob:

Yup! There are all sorts of 'possible' possibilities, all without proof,

but it DOES WORK!

Many of our aircraft are 40+ years old. The original lubricants in the

switches have long disappeared.

They are NOT sealed switches.

What has worked for many years are now failing. Just look Brandon's post

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bsvantho

Joined: 16 Apr 2018

Posts: 3

|

Posted: Fri Apr 20, 2018 11:18 am Post subject: Re: Z-12 contactor failure Posted: Fri Apr 20, 2018 11:18 am Post subject: Re: Z-12 contactor failure |

|

|

Agree the certified electrical system is much weaker and I found first hand that master switches are not well maintained, but I will attempt to bring this back around to the intent of my original post...

Not trying to reinvent anything. This will most likely remain a philosophical discussion for me as Z-12 is already quite robust as compared to the certified planes I fly in that E-bus devices will still be available on battery + internal battery backups, etc.

I have found very little information specific to protecting for master contactor failure. So is the philosophy for Z-12 that it is not worth worrying about since E-bus will still operate? I can accept this, I just am confused when I see Z-13/8 that connects the alternator on the battery side. Can anyone explain the reason for the difference?

Thanks,

-Brendon

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Apr 20, 2018 12:30 pm Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 12:30 pm Post subject: Z-12 contactor failure |

|

|

Brendon:

Here is the schematic of the Z-13/8

http://www.aeroelectric.com/PPS/Adobe_Architecture_Pdfs/Z13-8T.pdf

The NOTES are not on this schematic.

But, you can see the Alternator is on the LOAD side of Relay / Battery Contactor. So, the relay has to be closedÂ

for Alternator to function.

I could not find a link for the Z-12 ;-(

But, consider this:

Many people like a Avionics Master Switch.

The switch itself has a BACK-UP.

It is usually a SECOND heavy duty switch either in Parallel with the main Avionics Master Switch <-- Used when the Main switch is the ONLY means closing the circuit.

The other location is across a Avionics Master Relay. The Main Avionics Master Switch closes a Relay <-- Not the best way of doing things but it works. So, when the BACK-UP Avionics Master Switch is closed it bypasses the relay and applies power to the Avionics circuit.

Using this same type of configuration you can use for the MASTER SWITCH. Put a BACK-UP Master Switch in Parallel with the Main Master Switch. The only problem there is you have to REMEMBER to Shut Off the MAIN MASTER SWITCH and Double Check that the BACK-UP switch is OFF.

Totally doable on Experimental. Not doable on certified, not without a 337!

Barry

On Fri, Apr 20, 2018 at 3:18 PM, bsvantho <bsvantho(at)gmail.com (bsvantho(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "bsvantho" <bsvantho(at)gmail.com (bsvantho(at)gmail.com)>

Agree the certified electrical system is much weaker and I found first hand that master switches are not well maintained, but I will attempt to bring this back around to the intent of my original post...

Not trying to reinvent anything. This will most likely remain a philosophical discussion for me as Z-12 is already quite robust as compared to the certified planes I fly in that E-bus devices will still be available on battery + internal battery backups, etc.Â

I have found very little information specific to protecting for master contactor failure. So is the philosophy for Z-12 that it is not worth worrying about since E-bus will still operate?  I can accept this, I just am confused when I see Z-13/8 that connects the alternator on the battery side. Can anyone explain the reason for the difference?

Thanks,

-Brendon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=479462#479462

====================================

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Fri Apr 20, 2018 12:49 pm Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 12:49 pm Post subject: Z-12 contactor failure |

|

|

On 4/20/2018 2:18 PM, bsvantho wrote:

| Quote: |

Agree the certified electrical system is much weaker and I found first hand that master switches are not well maintained, but I will attempt to bring this back around to the intent of my original post...

Not trying to reinvent anything. This will most likely remain a philosophical discussion for me as Z-12 is already quite robust as compared to the certified planes I fly in that E-bus devices will still be available on battery + internal battery backups, etc.

I have found very little information specific to protecting for master contactor failure. So is the philosophy for Z-12 that it is not worth worrying about since E-bus will still operate? I can accept this, I just am confused when I see Z-13/8 that connects the alternator on the battery side. Can anyone explain the reason for the difference?

Thanks,

-Brendon

I *think* that what you're seeing in z13-8 is that the primary alt is

|

connected conventionally, to the bus side of the master contactor. The

*backup* (much lower current capability) alt is connected to the battery

side of the contactor, so that in the event of a primary alt failure,

you can shed the load of the main bus *and* the load of the master

contactor (coil consumes 1/2-1 1/2 amps just to keep it engaged), and

still have the backup alt available to sustain the battery bus and

endurance bus. If it was on the other side of the master contactor, you

couldn't shed the main bus and contactor loads in the event of a main

alt failure.

Charlie

---

This email has been checked for viruses by Avast antivirus software.

https://www.avast.com/antivirus

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bsvantho

Joined: 16 Apr 2018

Posts: 3

|

Posted: Fri Apr 20, 2018 1:13 pm Post subject: Re: Z-12 contactor failure Posted: Fri Apr 20, 2018 1:13 pm Post subject: Re: Z-12 contactor failure |

|

|

| ceengland7(at)gmail.com wrote: | On 4/20/2018 2:18 PM, bsvantho wrote:

| Quote: |

Agree the certified electrical system is much weaker and I found first hand that master switches are not well maintained, but I will attempt to bring this back around to the intent of my original post...

Not trying to reinvent anything. This will most likely remain a philosophical discussion for me as Z-12 is already quite robust as compared to the certified planes I fly in that E-bus devices will still be available on battery + internal battery backups, etc.

I have found very little information specific to protecting for master contactor failure. So is the philosophy for Z-12 that it is not worth worrying about since E-bus will still operate? I can accept this, I just am confused when I see Z-13/8 that connects the alternator on the battery side. Can anyone explain the reason for the difference?

Thanks,

-Brendon

I *think* that what you're seeing in z13-8 is that the primary alt is

|

connected conventionally, to the bus side of the master contactor. The

*backup* (much lower current capability) alt is connected to the battery

side of the contactor, so that in the event of a primary alt failure,

you can shed the load of the main bus *and* the load of the master

contactor (coil consumes 1/2-1 1/2 amps just to keep it engaged), and

still have the backup alt available to sustain the battery bus and

endurance bus. If it was on the other side of the master contactor, you

couldn't shed the main bus and contactor loads in the event of a main

alt failure.

Charlie

---

This email has been checked for viruses by Avast antivirus software.

https://www.avast.com/antivirus |

This makes perfect sense to me. Now look at Z-12 - the primary and backup alternators are both connected the same way - to the main bus. If you turn off the master both alternators are isolated from the battery. This means battery only operation unless the alternators remain stable without battery. Why do it this way? The only difference I see is the backup alternator is the larger 20A vs 8A.

To ask another way. Why not connect the larger 20A backup alternator in the same way as Z-13/8 ( with relay and switch )? Is this not advisable due to the higher current being switched or some other reason?

-Brendon

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Fri Apr 20, 2018 1:51 pm Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 1:51 pm Post subject: Z-12 contactor failure |

|

|

On 4/20/2018 4:13 PM, bsvantho wrote:

| Quote: |

ceengland7(at)gmail.com wrote:

> On 4/20/2018 2:18 PM, bsvantho wrote:

>

>>

>>

>> Agree the certified electrical system is much weaker and I found first hand that master switches are not well maintained, but I will attempt to bring this back around to the intent of my original post...

>>

>> Not trying to reinvent anything. This will most likely remain a philosophical discussion for me as Z-12 is already quite robust as compared to the certified planes I fly in that E-bus devices will still be available on battery + internal battery backups, etc.

>>

>> I have found very little information specific to protecting for master contactor failure. So is the philosophy for Z-12 that it is not worth worrying about since E-bus will still operate? I can accept this, I just am confused when I see Z-13/8 that connects the alternator on the battery side. Can anyone explain the reason for the difference?

>>

>> Thanks,

>>

>> -Brendon

>>

>> I *think* that what you're seeing in z13-8 is that the primary alt is

>>

> connected conventionally, to the bus side of the master contactor. The

> *backup* (much lower current capability) alt is connected to the battery

> side of the contactor, so that in the event of a primary alt failure,

> you can shed the load of the main bus *and* the load of the master

> contactor (coil consumes 1/2-1 1/2 amps just to keep it engaged), and

> still have the backup alt available to sustain the battery bus and

> endurance bus. If it was on the other side of the master contactor, you

> couldn't shed the main bus and contactor loads in the event of a main

> alt failure.

>

> Charlie

>

> ---

> This email has been checked for viruses by Avast antivirus software.

> https://www.avast.com/antivirus

This makes perfect sense to me. Now look at Z-12 - the primary and backup alternators are both connected the same way - to the main bus. If you turn off the master both alternators are isolated from the battery. This means battery only operation unless the alternators remain stable without battery. Why do it this way? The only difference I see is the backup alternator is the larger 20A vs 8A.

To ask another way. Why not connect the larger 20A backup alternator in the same way as Z-13/8 ( with relay and switch )? Is this not advisable due to the higher current being switched or some other reason?

-Brendon

I'd bet that the reason is implied in the text descriptions preceding

|

the drawings. With the bigger backup alt, there's no reason to turn off

the master (except fire, in which case you want the alternators off line

just like the rest of the electrical system). Note also that the larger

backup alt uses an external regulator to supply field voltage, so the

regulator would have to be moved to the endurance bus, as well, if you

intend to shut off the master & keep the backup on line.

I confess it's been a while since I studied the diagrams, but they've

endured for quite a while with people prodding at them, so I suspect

that the real issue is discovering the logic, rather than questioning

whether there is logic.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Apr 20, 2018 2:22 pm Post subject: Z-12 contactor failure Posted: Fri Apr 20, 2018 2:22 pm Post subject: Z-12 contactor failure |

|

|

At 03:28 PM 4/20/2018, you wrote:

not necessarily so . . . some alternators

need some help from the battery to get

started but once excited and on-line, they

will continue to function even if the battery

contactor is opened

Bonanzas and Barons are fitted with alternators

that self excite . . . the alternator(s) and

battery are on separate switches. The POH speaks

to alternator-only operations which are permissable.

The e-bus is a work-around for contactor failure.

The s/b alternator in z13/8 will come on line

whether or not the battery contactor is closed.

Contactor failure in flight is exceedingly rare.

A contactor that's going bad will offer some issues

for getting the engine started . . . your FIRST

and very valuable clue that it's time to change

the puppy out.

So what's the source of the heartburn over contactor

failures?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Apr 21, 2018 4:39 am Post subject: Z-12 contactor failure Posted: Sat Apr 21, 2018 4:39 am Post subject: Z-12 contactor failure |

|

|

Agree the certified electrical system is much weaker and I found first hand that master switches are not well maintained, but I will attempt to bring this back around to the intent of my original post...

Not trying to reinvent anything. This will most likely remain a philosophical discussion for me as Z-12 is already quite robust as compared to the certified planes I fly in that E-bus devices will still be available on battery + internal battery backups, etc.

I have found very little information specific to protecting for master contactor failure.

Because it's so rare . . . and, with the carefully

contrived architecture and preventative maintenance,

it's failure does not represent a hazard to comfortable

termination of flight.

So is the philosophy for Z-12 that it is not worth worrying about since E-bus will still operate?

The whole airplane will probably operate. Z-12 is simply

an illustration of how the secondary, engine driven alternator

was incorporated into TC aircraft. It was simply added to

the distribution system as a second source with the ability

to support plenty of electro-whizzies on the panel.

I can accept this, I just am confused when I see Z-13/8 that connects the alternator on the battery side. Can anyone explain the reason for the difference?

Sure. Z13/8 is a three layer electrical system.

(1) Battery only. E-bus powered appliances, no contactor loads

Endurance implications: "Plan C" loads tailored to

known battery capacity such that battery-only endurance

goals are met.

(2) Battery + 8. E-bus powered appliances, contactor load

optional depending on "Plan B" loads. Loads tailored

to hold battery in reserve for descent and approach

to landing. Electrical endurance essentially unlimited.

Descent and approach to landing loads can depend on

known battery capacity to supplement the 8A engine

driven power source.

(3) Battery + Main Alternator. Normal "Plan A" ops. No

limits on electrical loads.

The three-layer system is practical only on OBAM aircraft

. . . the 337 or STC to convert a TC aircraft would be

prohibitive and would not materially reduce risk.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Apr 21, 2018 9:14 am Post subject: Z-12 contactor failure Posted: Sat Apr 21, 2018 9:14 am Post subject: Z-12 contactor failure |

|

|

| Quote: |

This makes perfect sense to me. Now look at Z-12 - the primary and backup alternators are both connected the same way - to the main bus. If you turn off the master both alternators are isolated from the battery. This means battery only operation unless the alternators remain stable without battery. Why do it this way? The only difference I see is the backup alternator is the larger 20A vs 8A.

To ask another way. Why not connect the larger 20A backup alternator in the same way as Z-13/8 ( with relay and switch )? Is this not advisable due to the higher current being switched or some other reason? |

The e-bus was conceived one evening about 1988 in

conversation with a LongEz builder in California.

This fellow did a lot of long distance travel over

mountains. I don't recall if his airplane had a

starter . . . don't think it did because I do

recall that he was fitted with a pretty light

battery in the nose.

The design goal being pondered was how to create

a battery-only endurance greater than his fuel

endurance . . . which was rather long.

At that time, his electrical endurance loads were

as I recall, about 3 amps. A battery contactor draws

about 0.8A after warm up . . . enough snort to run

a couple of useful electro-whizzies yet this energy

was tossed off as heat. His SD-8 would support normal

flight loads including contactor.

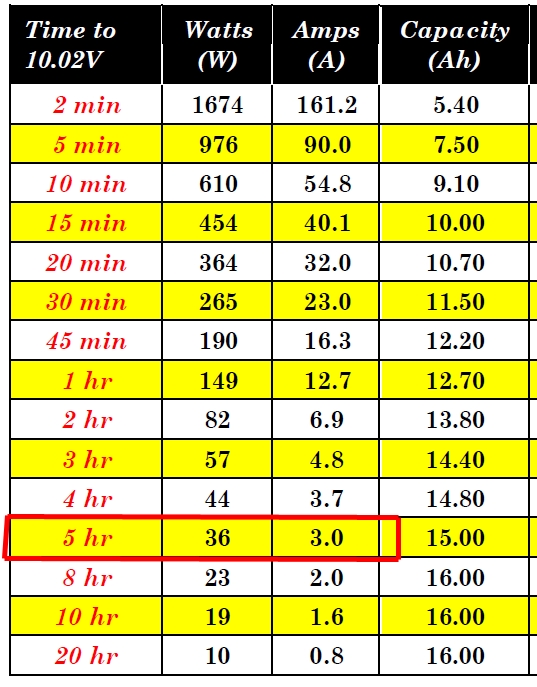

[img]cid:.0[/img]

His endurance loads must have been a bit less than

3A because I recall we decided that a new 18a.h.

battery would carry his anticipated loads for 6

hours, hence his 4-hour design goal would be

satisfied to 75% of new capacity whereupon

the battery gets replaced.

So the e-bus was conceived as a method for setting

up a fixed, predictable battery-only endurance load

with a simple re-positioning of two switches.

Lots of Ez aircraft had only SD8 alternators on

the drive pad, no other alternator and no starter.

The B&C line of light weight starters and alternators

encouraged the Ez crowd on to the next evolutionary

step.

Added weight on the extreme rear of the a/c drove

a need for ballast in the nose . . . ballast

that was best achieved with a larger battery as

opposed to bags of lead shot! The 24 a.h. battery

was the next step up.

The SD-8 could be left in place on the drive pad for a

weight penalty of about 4 pounds. Hence, Z13/8 germinated

from the evolving goals of Long-Ez owners in the 1990

time frame.

At one time, I did have a Z13/20 architecture which

was discussed here on List and I think a few installations

were made. I was never happy with it as it offered

no particular advantages over Z12 and was un=necessarily

complex. There was no pressing need to eliminate contactor

loads on the much larger S/B alternator so it was

removed from the 'Connection after a few years.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

235.4 KB |

| Viewed: |

27932 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Apr 21, 2018 9:24 am Post subject: Z-12 contactor failure Posted: Sat Apr 21, 2018 9:24 am Post subject: Z-12 contactor failure |

|

|

| Quote: | His endurance loads must have been a bit less than

3A because I recall we decided that a new 18a.h.

battery would carry his anticipated loads for 6

hours, hence his 4-hour design goal would be

satisfied to 75% of new capacity whereupon

the battery gets replaced. |

Hmmmm . . . my recollection of details may be

a bit fuzzy after 30 years, 4 hours is 66%

of new . . . anyhow, this illustrates the

thought processes for design decisions.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Apr 23, 2018 8:03 am Post subject: Z-12 contactor failure Posted: Mon Apr 23, 2018 8:03 am Post subject: Z-12 contactor failure |

|

|

Bob:

Yup There are all sorts of 'possible' possibilities, all without proof, but it DOES WORK!

Many of our aircraft are 40+ years old. The original lubricants in the switches have long disappeared.

They are NOT sealed switches.

What has worked for many years are now failing. Just look Brandon's post.

And, when it comes to the Stall Warning micro switch - Replacement with NEW is $1200+ used, about $600 to $700.

All this can be prevented with a can of WD-40!

WD40 can be useful in the maintenance of electro-whizzies

with moving parts . . . and indeed, it was not originally

designed to be a lubricant so much as a (W)ater (D)isplacer

and cleaner. As a side benefit, it does have some degree of

lubricity . . . as do many substances . . . but its service

life as a lubricant is far outpaced by other products designed

for lubrication.

https://goo.gl/sbPhXj

WD40 was major maintenance feature for the MQM107 target

we used to build at Beech.

https://goo.gl/otFkbp

The engine was a very short service life device with

minimal moving parts and INTENDED to become totally

immersed in seawater during an offshore recovery.

The first refurbishment move for the aircraft was to remove

the engine and submerge it in a barrel of WD40. When the

aircraft was ready to receive the engine, they hauled it out

with compressed air and bolted it back on the airframe[/b].

Not needed on sealed DPST Toggle Switches. AND they are NOT 40+ years old.

Obviously, a truly sealed switch cannot benefit from

spray on remedies . . .

[/b]I can't see how applying a lubricant like WD40 can be advantageous to the contacts on the switch...surely there will be burning volatiles or lube which would affect the service or life of the part? On the moving parts yes but I don't know of a way to differentiate with a spray can.

WD40 is often applied to moving part for

the purpose of loosening corrosion and flushing

out small particulates while displacing any

moisture present. The combustible VOLATILES are

just that . . .they quickly dissipate after carrying

WD40 'magic juice' to the intended surfaces.

[/b]If the Master Switch failed why reinvent the wheel?

Since this was a certified plane you are forced to work with the design of the time.

What I have found is 99.982% of certified plane owners and A&P's, NEVER address the Master Switch during Annual.

It should be addressed every Annual and it is very easy to do:

1 - Spray the heck out of it with Contact Cleaner.

2 - Cycle the switch a couple of dozen times.

3 - Spray it with WD-40.

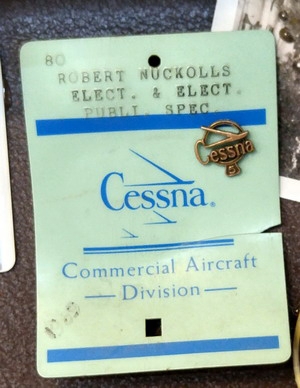

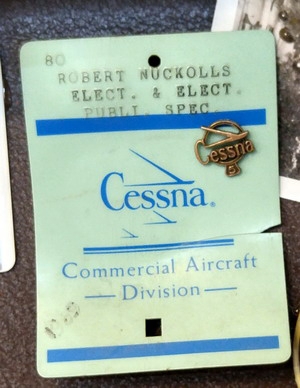

My first job at Cessna extended over 5 years

in the technical publications department where,

among other things, I wrote repair and preventative

maintenance narratives in Cessna's service manuals.

[img]cid:.0[/img]

The policy of the company was to 'replace on condition'

meaning that devices like relays and toggle switches

were considered and sometimes tested to see that

they met service life design goals. If a such a device

were to mis-behave, it was time to replace it. Hence

no maintenance or refurbishment methods were offered

or required.

[/b]Side Note: This also goes for the micro-switch in the Stall Warning System.

The basic switch used on the legacy stall warning

sensor was a Honeywell BZ series commercial off

the shelf device with very low operating force

(measured in grams). Of course, as a component

in a PMA/TSO product, the owner operator was prohibited

from replacing said switch for $20 (and I wasn't

allowed to write a procedure for it either).

These are not sealed switches and they're mounted

in one of the more hostile environments on the airplane.

Depending on the mis-behavior mode, an application

of WD40 may well free up things and restore normal

operation . . . but a switch that was not working

normally was probably pretty long in the tooth. Depending

on criticality of the device, it may well be better

to replace as opposed to refurbish the individual

switch.

[/b]On Experimental Aircraft you have a HUGE ADVANTAGE...

Use a Heavy Duty Master Switch and a Separate Heavy Duty Alternator Switch.

I use DPST switches and tie BOTH sides together. This DOUBLES the physical as well as the electrical rating of the switch.

Paralleling contacts only doubles the CARRY

rating of a switch . . . it does not double

opening or closing ratings.

[/b]Want to go extra fancy? Look for switches that are Sliver Plated.

Silver plating or solid silver contacts are

rare and intended for specific applications . . .

which generally do not include switching

DC power. Cadmium Silver contacts are used in

the more robust designs favored by mil-spec

designs . . . but I suspect the Carling style

products used on hundreds of thousands of TC

aircraft are not so 'fancy' . . . yet demonstrably

adequate to task.

[/b]You can also use switches that have a built in Dust/Moisture shield. OR... Install the dust/Moisture shield over the Toggle Lever.

Side Note: On certified planes with the standard split Master/Alt Switch, there are four (4) failure points:

1 - The Physical snap action of the switch.

2 - The Electrical contacts of the switch.

3 - Fast-On tabs on the back of the switch.

4 - The Physical MOUNTING of the switch. There is a snap in bezel that holds the switch into the panel.

This bezel fails as the ears either break off or loose their spring action.

Then the switch vibrates forward and shorts out to the aluminum panel.

The cure is to use two (2) sheet metal round head screws on either side to hold the bezel in place.

If the switch vibrates out it will short out and take your Master/Alt switch and Starter Relay out of the circuit.

If you are airborne - You loose even the ability to go to Battery Back-up.

Or do an in-flight re-start.

Scary!

Can you cite any service difficulty report

that describes such a failure of the mounting?

These switches are used by hundreds of thousands

for about 50 years. I find it curious that

anyone would find them (1) lacking in design

to intended task and/or (2) figuring significantly

on the list of probable failure that creates

a hazard to flight.

[/b]I know it is not a likely case, but I have experienced a contactor failure on a production plane in flight. It ended up that the root cause was a defective master switch - but the result was the same. Because there was no endurance bus alternate feed, it was a full electrical shutdown, in IMC no less!

Then it wasn't a contactor failure but a switch failure.

How did it manifest in flight? i.e. how did you become

aware of the failure? Did things simply go black?

[/b]I would like to know if there is a practical way to protect for contactor failure ( other than battery only operation ) with the Z-12 design. It would be nice to have a second path to the battery from aux alternator to ensure stable power if the master does fail.

You can move the aux alternator wiring to the

hot side of the battery contactor . . . it's

just that simple.

[/b]The appeal to me of having an aux alternator is to be able to continue flight on one alternator. This is only possible if either a battery connection is maintained always or it is a guarantee the alternator will provide stable power without a battery connection.

Batteryless operation is likely but cannot

be guaranteed without testing on your airplane

with your constellation of hardware. As I've mentioned,

there are Beechcraft piston aircraft wherein battery-off

operation is described and permitted as a matter of

design and verification by flight testing. It's covered

in the POH.

For this forum cannot make configuration/operation

recommendations without conducting similar investigations

as to meeting design goals

[/b]The Z-13/8 uses a relay with the SD-8 alternator to connect directly to battery. Is this design practical or even advisable with the SD-20 alternator? With Z-13/8 the aux alternator will provide power to battery bus and E-BUS if contactor fails.

Exactly. If you wish, you can certainly wire the SD20

in a manner suggested by Z13/8. There are no 'rules'

that would prohibit you from doing so.

When I took Z13/20 off the table about 10 years ago,

it was because it added a degree of complexity

over Z12 that did not materially reduce risk.

In fight contactor failure is exceedingly rare.

Smoke in the cockpit probably has a higher degree

of probability . . . in which instance you may

wish to shot the whole system down anyhow.

Any of you who have attended my weekend seminars

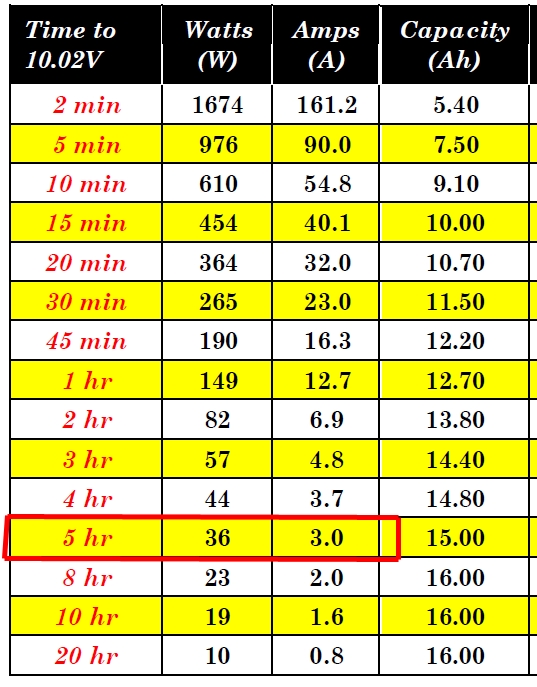

may remember this slide:

[/b][img]cid:.0[/img][/b]

The last 200-300 hours of my flying days were

carried out with these three items in my flight

bag. Since I flew nothing but rentals, I had little

insight as to the history of electrical/electronics

systems. I was prepared to continue flight to intended

destination with the master switch OFF.

Indeed, the performance of these $100 hand-held

gps receivers so exceeded the panel mounted stuff

that those last hundreds of hours were flown with

DUAL gps receivers 'mounted' to the glare-shield

and windshield with little blobs of windshield

sealant. Never touched a VOR receiver or even

the panel mounted GPS receivers again.

As I describe in Chapter 17 of the 'Connection,

system reliability has far more to do with pilot

skills and careful crafting of a Plan-B than it

does on any selection of system hardware. The

carefully crafted architecture and pilot's personal

bag of tricks strives for failure tolerance . . . not

failure proofing. The later cannot be achieved.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

79.03 KB |

| Viewed: |

27906 Time(s) |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Mon Apr 23, 2018 6:14 pm Post subject: Z-12 contactor failure Posted: Mon Apr 23, 2018 6:14 pm Post subject: Z-12 contactor failure |

|

|

Bob:

You are going off on tangents - - -

On Mon, Apr 23, 2018 at 12:02 PM, Robert L. Nuckolls, III <

nuckolls.bob(at)aeroelectric.com> wrote:

[quote] Bob:

Yup There are all sorts of 'possible' possibilities, all without proof,

but it DOES WORK!

Many of our aircraft are 40+ years old. The original lubricants in the

switches have long disappeared.

They are NOT sealed switches.

What has worked for many years are now failing. Just look Brandon's post

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bob.verwey(at)gmail.com

Guest

|

Posted: Mon Apr 23, 2018 9:06 pm Post subject: Z-12 contactor failure Posted: Mon Apr 23, 2018 9:06 pm Post subject: Z-12 contactor failure |

|

|

Gee Wizz Barry,

Many have taken on Bob N, and many have failed....

In all the 15 + years I have been a member of this forum, the thing that has impressed me most is the decorum of the participants....just sayin!  Â

Best...Bob Verwey

082 331 2727

[img]https://docs.google.com/uc?export=download&id=0B5d7rgAInTuTUUZsUjY4QmJsdVU&revid=0B5d7rgAInTuTdDJDaXRFZVh3b3lMa3FWL0s3MFdzc01YRlNvPQ[/img]

On 24 April 2018 at 04:12, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: | Bob:

You are going off on tangents - - -Â

On Mon, Apr 23, 2018 at 12:02 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | Bob:

Yup There are all sorts of 'possible' possibilities, all without proof, but it DOES WORK!

Many of our aircraft are 40+ years old. The original lubricants in the switches have long disappeared.

They are NOT sealed switches.

What has worked for many years are now failing. Just look Brandon's post.

And, when it comes to the Stall Warning micro switch - Replacement with NEW is $1200+ used, about $600 to $700.

All this can be prevented with a can of WD-40!

WD40 can be useful in the maintenance of electro-whizzies

with moving parts . . . and indeed, it was not originally

designed to be a lubricant so much as a (W)ater (D)isplacer

and cleaner. As a side benefit, it does have some degree of

lubricity . . . as do many substances . . . but its service

life as a lubricant is far outpaced by other products designed

for lubrication.

|

âBarry - Nobody said it was being used as a lubricant, only you. It will work as a lubrcant to the contact areas of plastic switches and even the metal pivot points. How long will it last? I don't know... As I said in my post; A&P seldom address switches and many of these switches are 40 + years old. So, anything that one can do to extend their life or rejuvenate them is a good thing. Back to the WD... It is being used â

âas a WD and as a CLEANER!

Oh wait... Can it be used as a cleaner???

DEFINITELY YES!â

Do you have proof that it can't be?

| Quote: | https://goo.gl/sbPhXj

WD40 was major maintenance feature for the MQM107 target

we used to build at Beech.

|

âBarry - So!!! Who cares!â

Â

| Quote: |

https://goo.gl/otFkbp

The engine was a very short service life device with

minimal moving parts and INTENDED to become totally

immersed in seawater during an offshore recovery.

|

âBarry - Want more info on this subject? I did salvage and artifact recovery way-way back in the 70's and 80's .

Who cares!â

Â

| Quote: |

The first refurbishment move for the aircraft was to remove

the engine and submerge it in a barrel of WD40. When the

aircraft was ready to receive the engine, they hauled it out

with compressed air and bolted it back on the airframe.

Not needed on sealed DPST Toggle Switches. AND they are NOT 40+ years old.

Obviously, a truly sealed switch cannot benefit from

spray on remedies . . .

|

âBarry - That's why I said you CYCLE the Switches a couple dozen times.â

Â

âWhy are you going off on so many tangents?â

| Quote: |

I can't see how applying a lubricant like WD40 can be advantageous to the contacts on the switch...surely there will be burning volatiles or lube which would affect the service or life of the part? On the moving parts yes but I don't know of a way to differentiate with a spray can.

WD40 is often applied to moving part for

the purpose of loosening corrosion and flushing

out small particulates while displacing any

moisture present. The combustible VOLATILES are

just that . . .they quickly dissipate after carrying

WD40 'magic juice' to the intended surfaces.

|

âBarry - You advertise yourself as an engineer. â

âIf so, why are you so closed minded to other possibilities?â

There are curtain things in physics that cannot be changed, but how a product can be used and to Great Advantages is sure out there.Â

| Quote: |

If the Master Switch failed why reinvent the wheel?Â

Since this was a certified plane you are forced to work with the design of the time.

What I have found is 99.982% of certified plane owners and A&P's, NEVER address the Master Switch during Annual.

It should be addressed every Annual and it is very easy to do:

1 - Spray the heck out of it with Contact Cleaner.

2 - Cycle the switch a couple of dozen times.

3 - Spray it with WD-40.Â

My first job at Cessna extended over 5 years

in the technical publications department where,

among other things, I wrote repair and preventative

maintenance narratives in Cessna's service manuals.

|

âBarry - So what? Anybody can sit down behind a desk and write a manual.

I have for a few dozen Environmental Test procedures. ANYTHING can be written. Â

Ask the A&P and IA that is TRY to follow â

âwhat some paper-pusher âwrote IF it is possible.

Ask the plane owner who has to pay the bill why a simple thing like the Cessna Seat Rail Tracks has to be replace and WHY it is so expensive!â Or how to replace the Flap Motor on a Cessna.â

| Quote: |

[img]cid:.0[/img]

The policy of the company was to 'replace on condition'

meaning that devices like relays and toggle switches

were considered and sometimes tested to see that

they met service life design goals. If a such a device

were to mis-behave, it was time to replace it. Hence

no maintenance or refurbishment methods were offered

or required. Â

Side Note:Â This also goes for the micro-switch in the Stall Warning System.

The basic switch used on the legacy stall warning

sensor was a Honeywell BZ series commercial off

the shelf device with very low operating force

(measured in grams). Of course, as a component

in a PMA/TSO product, the owner operator was prohibited

from replacing said switch for $20 (and I wasn't

allowed to write a procedure for it either).

These are not sealed switches and they're mounted

in one of the more hostile environments on the airplane.

Depending on the mis-behavior mode, an application

of WD40 may well free up things and restore normal

operation . . . but a switch that was not working

normally was probably pretty long in the tooth. Depending

on criticality of the device, it may well be better

to replace as opposed to refurbish the individual

switch.

On Experimental Aircraft you have a HUGE ADVANTAGE...

Use a Heavy Duty Master Switch and a Separate Heavy Duty Alternator Switch.

I use DPST switches and tie BOTH sides together. This DOUBLES the physical as well as the electrical rating of the switch.

Paralleling contacts only doubles the CARRY

rating of a switch . . . it does not double

opening or closing ratings.

Want to go extra fancy? Look for switches that are Sliver Plated.

Silver plating or solid silver contacts are

rare and intended for specific applications . . .

which generally do not include switching

DC power. Cadmium Silver contacts are used in

the more robust designs favored by mil-spec

designs . . . but I suspect the Carling style

products used on hundreds of thousands of TC

aircraft are not so 'fancy' . . . yet demonstrably

adequate to task.

|

âBarry - YES - They Are! But, as the fellow whom had the failure was talking and as I was saying:

These switches have NOT been addressed during Annuals over MANY - MANY YEARS! â

Â

âThe Experimental Owner has Great Advantages over the Certified Owner by making small changes that GREATLY extend the life and as you are so vigorous to report on 'Reduction of Failure Points'. So, why shouldn't they look for the better switch.

Silver Plated or CadSilver?

GAUD! Which way did you part the gnat's hairs on that one?

Walking into a electronics store, the Simple question: Do you have any Silver Plated Contact Switch? Will result in the SAME results! When I order Manure I don't care if it is horse or cow. Either one will work!

| Quote: |

You can also use switches that have a built in Dust/Moisture shield. OR... Install the dust/Moisture shield over the Toggle Lever.

Side Note:Â On certified planes with the standard split Master/Alt Switch, there are four (4) failure points:

1 - The Physical snap action of the switch.

2 - The Electrical contacts of the switch.

3 - Fast-On tabs on the back of the switch.

4 - The Physical MOUNTING of the switch.  There is a snap in bezel that holds the switch into the panel.

This bezel fails as the ears either break off or loose their spring action.

Then the switch vibrates forward and shorts out to the aluminum panel.

The cure is to use two (2) sheet metal round head screws on either side to hold the bezel in place.

If the switch vibrates out it will short out and take your Master/Alt switch and Starter Relay out of the circuit.

If you are airborne - You loose even the ability to go to Battery Back-up.

Or do an in-flight re-start.

Scary!

Â

Can you cite any service difficulty report

that describes such a failure of the mounting?

|

âBarry - You must LOVE AD's!

I found the problem twice. I fixed the problem twice.â

Â

âYES! The switches have lasted for many years. Does that mean they cannot fail? And, as I said: It was not the switch. It was the mounting bezel.

Just because a FAA 8070-1 report not exist AND I do not know if one does or does not exist, does not mean the problem does not exist.

âJust look at the design of the retaining bezel and even you should be able to see there is a potential failure point.

ESPECIALLY! When the switch is removed in tracking down a wiring issue.

There are more things in Heaven and Earth Horatio than even Bob has knowledge on.

Barry

| Quote: | Â Â These switches are used by hundreds of thousands

for about 50 years. I find it curious that

anyone would find them (1) lacking in design

to intended task and/or (2) figuring significantly

on the list of probable failure that creates

a hazard to flight.

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

79.03 KB |

| Viewed: |

27896 Time(s) |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Tue Apr 24, 2018 8:20 am Post subject: Z-12 contactor failure Posted: Tue Apr 24, 2018 8:20 am Post subject: Z-12 contactor failure |

|

|

. . . . Not wanting to venture into the dark side of some of these "conversations", I just want to relay what I have personally viewed on this subject of old switches and WD40.....

Some legacy Cessna switches were simple pull-push, like a Master. I have repaired 2 of them. If one is (very) careful bending the retaining tabs the switch can be worked apart and resealed. What I found in both was severely hardened original lubricate. Hardened to the point that if a piece gets into the contacts, it can cause a faults.

Cleaning with the usual sprays and re-lubing with modern electrical grease has fixed both and they are still working today.... but, it was the old lube that caused random failure. These were master switches.

About WD40, . . .I have used it on a lot to things, but this comment is about use on guns. I have pulled rifles from several years of storage and not been able to operate the bolt action. The one flaw I see with WD40 is that once the lighter carry fluids evaporate, it leaves a strong, thick film that can almost seize close fitting parts. Other than that issue, it does great duty as a penetrate and shield from water and rust. . . .

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Apr 24, 2018 9:04 am Post subject: Z-12 contactor failure Posted: Tue Apr 24, 2018 9:04 am Post subject: Z-12 contactor failure |

|

|

At 09:12 PM 4/23/2018, you wrote:

| Quote: | Bob:

You are going off on tangents |

I would like to think that I'm reviewing background

that supports ideas and design goals for reducing

risk. Airplanes are exceedingly unforgiving things . . .

but they are well understood. We can climb into these

machines and launch into hazardous environs with

confidence when we (1) don't routinely push the

'boundaries of the envelope'. (2) build and operate

with a degree of understanding that promotes

failure tolerance. (3) pay attention to the failings

that produce the vast majority of unhappy days in

the cockpit . . . most off-airport arrivals with

the earth have root cause in ignorance of or

inattention to important things.

There are no procedures in the legacy annual inspections

for switches, relays, contactors, light bulbs, etc.

Because these things DO cease to function with regularity

that has nothing to do with the calendar. If things

didn't break, FBOs would be out of business.

"Replace on condition" is the mantra of those who

endeavor to become licensed aviation mechanics

and technicians. Certification follows education

delivered hopefully by competent teachers. If

you've read any of my works on the website or

in the 'Connection, you will see that I try

to lay foundation for both the physics and the

philosophies I am reviewing.

The materials and practices we've grown up with

in TC aviation are a good place to start as

we strive for 'self certification' . . . indeed,

few folks bucking rivets on or stringing wires in an

RV are 'qualified' to work for an FBO. Hence, the

mission for the AeroElectric-List is to bring

the best-we've-learned-how-to-do in 100 years of

TC aviation into to the world of OBAM aviation.

And then, because we are not burdened with

the albatross of prolific regulation and bureaucracy,

ADVANCE the art in careful, considered steps that

do not increase risk.

This thread was about contactor failures. Yes,

they've been known to crap out. Cessna Service-Parts

sells a boat load of new ones every year. Yet

how many unhappy days in the cockpit are attributed

to contactor failures . . . or switches, relays, etc?

This suggest that they are a low risk failure in

TC aircraft . . . and with careful analysis of

failure modes, OBAM aviation is free to reduce those

risks still further.

The narrative of WD40 WAS anecdotal but I hope

useful. The flags that arose in my thinking were

about the notions you were citing about the lack

of refurbishment and/or regular inspection intervals.

Most devices give us advance clues as to their

distress before they fail outright. I suggest that

the FIRST time a switch, relay or contactor demonstrates

an electrical infirmity, it is time to replace it.

Some mechanical infirmities may benefit from

a lubrication/cleaning operation . . . but hopefully,

the decision is made from a position of informed

competence.

Bailing wire and pliers served my grandpa well . . .

indeed, proper dress for my friends out here

in the hinterlands includes a leather holster for

a robust pair of pliers. My son gave me a Leatherman for

Father's Day about 5 years ago . . . it too has become part

of my 'uniform'. My friends also carry cans of WD40

on their trucks. They may be running re-grooved tires

on their swathers. Some have no doubt dropped little

doses of 'magic elixir' into the filler caps on a

faltering battery.

My point is that any refurbishment activity on a

component of our airplanes is worthy of evaluation

for return on investment, assessment of risk and,

as we've learned in a century of TC aviation, REPLACE

ON CONDITION is never a bad idea.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|