|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

ogdenk

Joined: 05 Feb 2007

Posts: 41

Location: Syracuse, NY

|

Posted: Sun May 01, 2016 3:02 pm Post subject: Fuselage Side Skin Dimpling Posted: Sun May 01, 2016 3:02 pm Post subject: Fuselage Side Skin Dimpling |

|

|

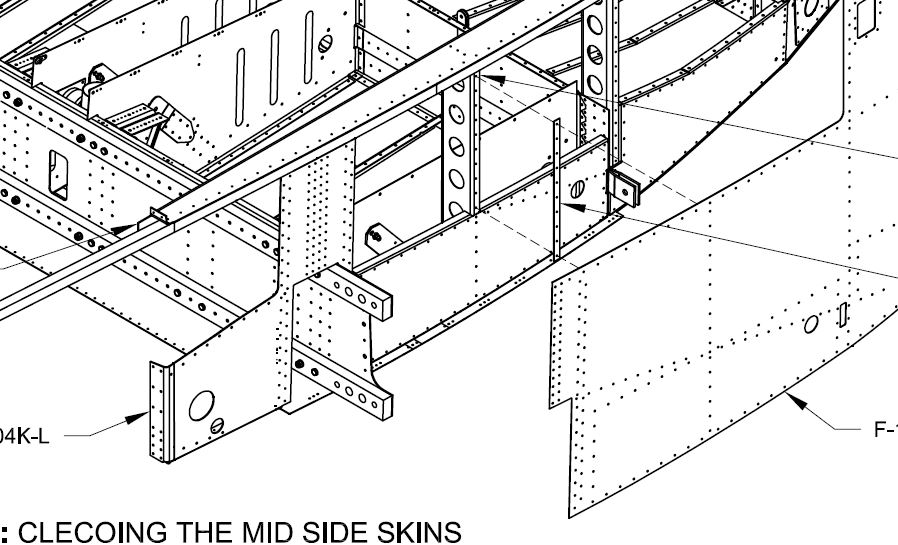

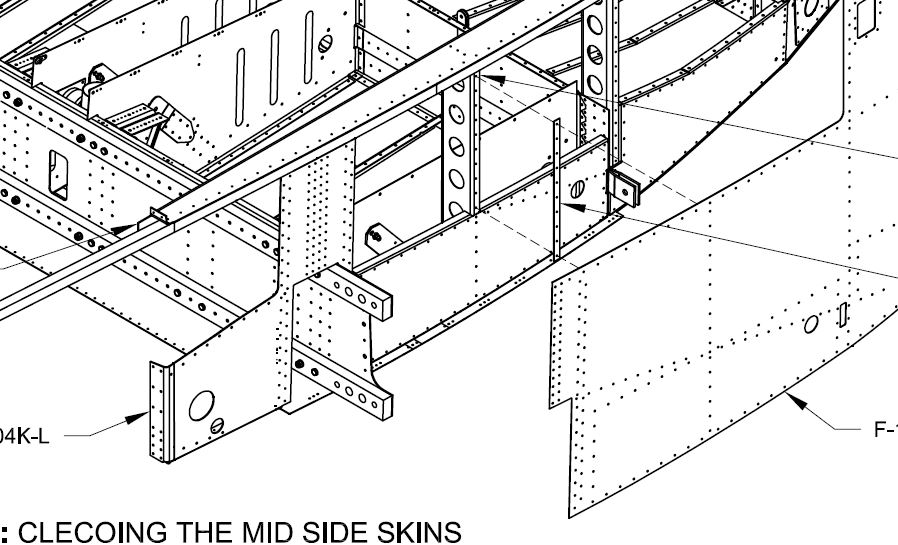

I have a question about the fuselage mid side skin dimpling. The instructions say to dimple all of the 3/32" holes that were drilled to the understructure. However, the corresponding holes in the F-1015A outboard seat ribs were not dimpled. They weren't specifically excluded from dimpling, but there was no step where they were dimpled so I didn't do it. This is the outboard rib immediately aft of the spar carry through. I have attached a clip of from the construction manual of this area. The holes in the F-1018 rear seat ribs (the next rib aft of the problem ribs) WERE dimpled as per the instructions.

It's going to be a pain to try and dimple those holes now. It looks like many of them will be hidden in the wing root area so I was thinking of using AN470 rivets in those holes instead of AN426. It looks like some of the holes will be above the wing though, so I will have to figure out a way to dimple those holes or countersink them. I do have a tight fit dimpling set that uses a rivet puller, but the performance is barely acceptable on thinner material. I will probably call Vans on this but I was wondering if others have dealt with this issue and what the resolution was.

Thanks for any thoughts/suggestions.

Kent Ogden

#40710

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

111.34 KB |

| Viewed: |

3252 Time(s) |

|

|

|

| Back to top |

|

|

Tim Olson

Joined: 25 Jan 2007

Posts: 2882

|

Posted: Sun May 01, 2016 7:35 pm Post subject: Fuselage Side Skin Dimpling Posted: Sun May 01, 2016 7:35 pm Post subject: Fuselage Side Skin Dimpling |

|

|

Hi Kent,

I don't remember the specific rib part numbers or anything, so this is

sort of off the cuff, but...

For the rivets that will be hidden in the wing root area, I don't see why

AN470's wouldn't be fine. I think the RV-14 kit used a lot of AN470's there.

And, if you have an area where you have a handful of rivets that are

visible and you want flush rivets, I don't think I'd worry too much about

countersinking a few of them if necessary. I too don't have great luck

with the pop-rivet dimple die set. I did just tonight pull out a vice-grips

dimple die to get some real tight ones...it's a vice grips with dimple dies

welded to them. If you have one of those maybe pull it out.

It's a handy tool when you need it.

At any rate, I wouldn't stress out too much if you're only looking to

countersink a handful

Tim

On 5/1/2016 6:02 PM, Kent Ogden wrote:

| Quote: | I have a question about the fuselage mid side skin dimpling. The

instructions say to dimple all of the 3/32" holes that were drilled to

the understructure. However, the corresponding holes in the F-1015A

outboard seat ribs were not dimpled. They weren't specifically

excluded from dimpling, but there was no step where they were dimpled

so I didn't do it. This is the outboard rib immediately aft of the

spar carry through. I have attached a clip of from the construction

manual of this area. The holes in the F-1018 rear seat ribs (the next

rib aft of the problem ribs) WERE dimpled as per the instructions.

It's going to be a pain to try and dimple those holes now. It looks

like many of them will be hidden in the wing root area so I was

thinking of using AN470 rivets in those holes instead of AN426. It

looks like some of the holes will be above the wing though, so I will

have to figure out a way to dimple those holes or countersink them. I

do have a tight fit dimpling set that uses a rivet puller, but the

performance is barely acceptable on thinner material. I will probably

call Vans on this but I was wondering if others have dealt with this

issue and what the resolution was.

Thanks for any thoughts/suggestions.

Kent Ogden

#40710

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jack(at)bedfordlandings.c

Guest

|

Posted: Mon May 02, 2016 3:48 am Post subject: Fuselage Side Skin Dimpling Posted: Mon May 02, 2016 3:48 am Post subject: Fuselage Side Skin Dimpling |

|

|

Hi Kent,

I’m at this stage myself. I thought about using AN470s but the skin has already been dimpled. I used the pop rivet dimpler where I could, and when I couldn’t I used a machine countersink – it’s been a couple of weeks since I did this and now the skins have been riveted on, but as I recall there were only 4 holes where the substructure was too thick to use the pop rivet dimpling tool. I countersunk those 4 holes and the countersink did not penetrate too far in the inside-most piece of structure to prevent forming a good shop head on the rivet.

The pop-rivet dimpler works ok on the rest of the holes.

Jack Phillips

#40610

Smith Mountain Lake, Virginia

Fuselage

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Kent Ogden

Sent: Sunday, May 1, 2016 7:02 PM

To: rv10-list(at)matronics.com

Subject: Fuselage Side Skin Dimpling

I have a question about the fuselage mid side skin dimpling. The instructions say to dimple all of the 3/32" holes that were drilled to the understructure. However, the corresponding holes in the F-1015A outboard seat ribs were not dimpled. They weren't specifically excluded from dimpling, but there was no step where they were dimpled so I didn't do it. This is the outboard rib immediately aft of the spar carry through. I have attached a clip of from the construction manual of this area. The holes in the F-1018 rear seat ribs (the next rib aft of the problem ribs) WERE dimpled as per the instructions.

It's going to be a pain to try and dimple those holes now. It looks like many of them will be hidden in the wing root area so I was thinking of using AN470 rivets in those holes instead of AN426. It looks like some of the holes will be above the wing though, so I will have to figure out a way to dimple those holes or countersink them. I do have a tight fit dimpling set that uses a rivet puller, but the performance is barely acceptable on thinner material. I will probably call Vans on this but I was wondering if others have dealt with this issue and what the resolution was.

Thanks for any thoughts/suggestions.

Kent Ogden

#40710

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|