|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

KeysFox

Joined: 05 Jan 2009

Posts: 137

|

Posted: Sat Oct 30, 2010 6:36 am Post subject: Prop Strike crank damage Posted: Sat Oct 30, 2010 6:36 am Post subject: Prop Strike crank damage |

|

|

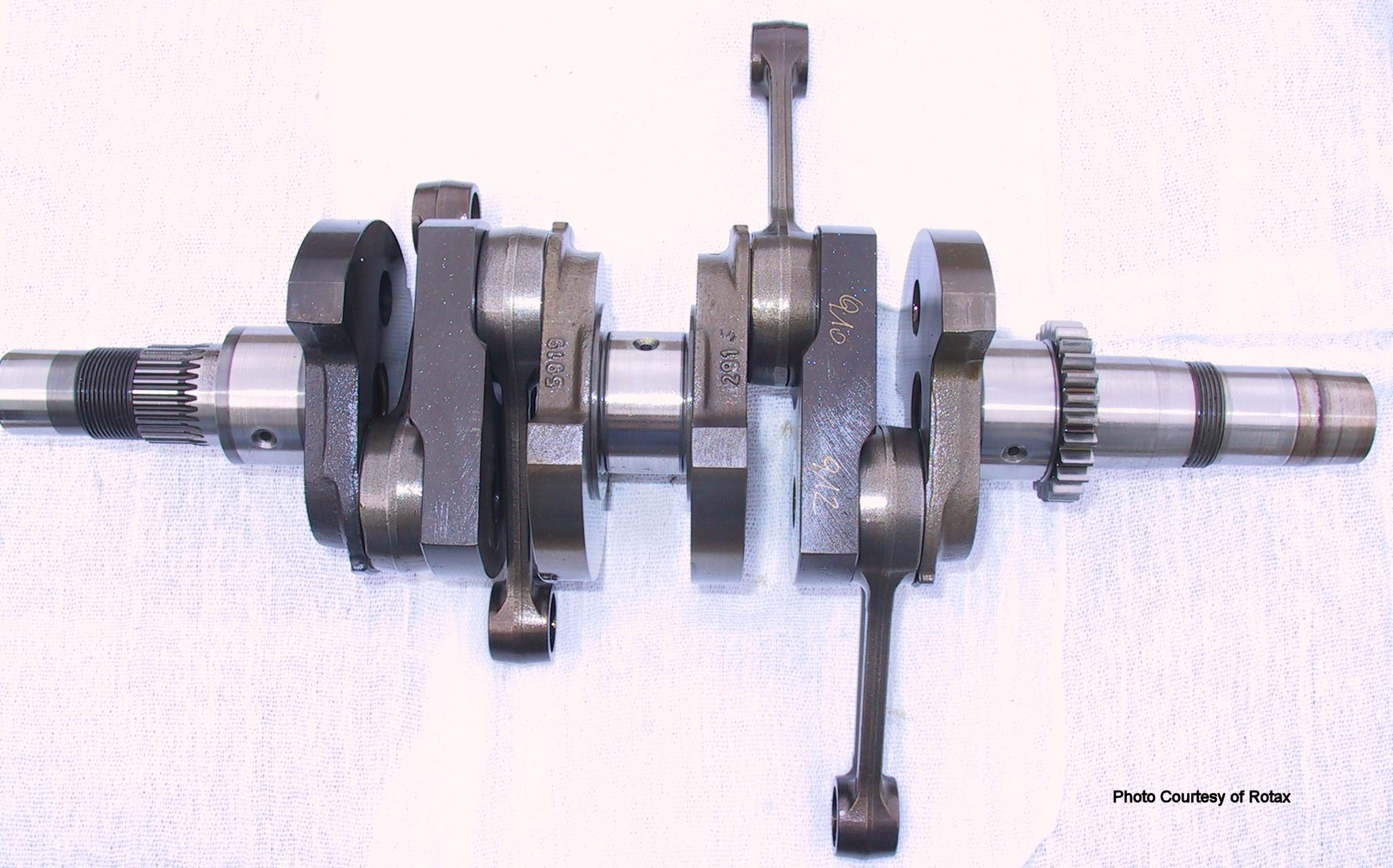

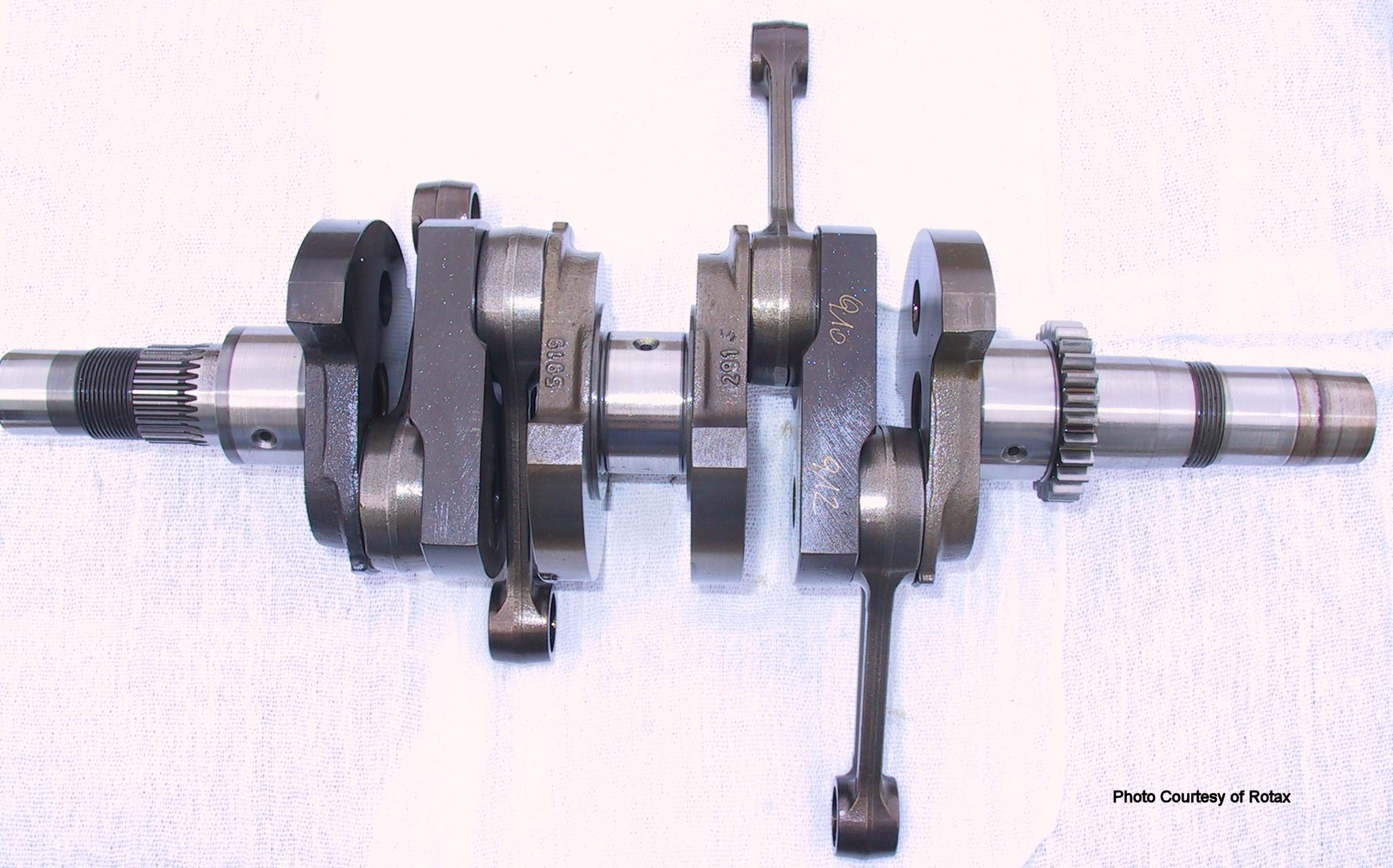

912 crank shafts are not one single piece of metal but units press fit

together.

Apparently, prior to the introduction of the slipper clutch in late model

gear boxes, prop strikes caused a rotation in the press together junctions

of the 912 crank shaft, which could not be detected by measuring prop

shaft flange "run out" at the gear case or crank shaft flange "run out".

Maybe 10 percent of 912 prop strikes result in crank shaft rotation,

primarily in older pre slipper clutch engines, and if not detected these

result in engine failure.

Crank shaft internal rotation has probably gone undiagnosed in many 912s

after prop strike. And my bet is prop strikes may not always show up in

logs, so buyers of used aircraft should probably ask questions if they

find indications that a prop or blades ahve been replaced.

I understand that Lockwood Aviation in Sebring, Florida can measure

internal rotation within the 912 crank shaft caused by prop strike.

Anyone having better information, or direct field experience on this might

want to chime in. My info is NOT from direct experience, but from what I

know to be a very knowlegable source.

BJ

N154K

>

| Quote: | In a message dated 10/30/2010 2:04:32 A.M. Central Daylight Time,

rotaxengines-list(at)matronics.com writes:

Because rotax 912 crank is composite (almost incredible for a 4 stroke

engine of

so high price) i'd like to know from rotax list experience if someone

else

has

experienced crankshaft problems on his 912 engine.

How do you figure the crank is composite ? Having held it in my hands it

is

made of metal like every other crank. It just comes as one

piece(including

the rods) and yes it can fail like every other engine crank.

Dick Maddux

912UL

Milton,Fl

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

B Jones

N154K

443-480-1023 |

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Sat Oct 30, 2010 7:03 am Post subject: Re: Prop Strike crank damage Posted: Sat Oct 30, 2010 7:03 am Post subject: Re: Prop Strike crank damage |

|

|

If you have a prop strike there is a procedure to follow. It isn't hard, but will tell you if you have further damage and absolutely needs to be done because you will not see the hidden damage with your eye. The procedure is in the maint manual under special checks. The gearbox needs inspection and the crank needs a run out check which can be done right there on the plane. The full amount of damage will also partly depend on whether you hit the ground at full throttle or at idle and depends on what prop you have on the plane. If you have a prop strike do the maint and be done with it. It will require a gearbox inspection and a run out check on the prop flange and shaft. You will be paying for a new oil shaft seal and a bearing. If the engine has a number of hours on it most likely 3 new bellview washers, too. About $160-$200 for all. If you really tagged the prop flange or bent the prop shaft add another $650. Thank God for the clutch because that will usually protect your crank. This is the perfect scenario about keeping you engine up.

For those that use 100LL all the time then you really need to pull the gearbox by 800 hrs. and send the clutch in to have all the lead paste removed because that will keep it from functioning correctly or even keep it from working at all.

If you have a strike I can do the inspections.

PLEASE,

I can not stress enough that if Rotax engine owners, 2 stroke or 4, maintained their engines per the maint manuals there would be a lot less problems or failures. I know it is a machine and yes something could go wrong even if maintained right, but that number is way down if proper maint is followed. Please do yourself a favor and the person that might be sitting next to you in the cockpit do your preventive maint. on both the engine and fuselage per the Mfgs. recommendation and don't try to save a few dollars or get poor advise from a neighbor. There are accidents and failures and the majority of the time caused by the owner from either incorrect or lack of maint.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

Dick Maddux

Joined: 24 Jun 2008

Posts: 516

Location: Milton, Fl

|

Posted: Mon Nov 01, 2010 3:55 am Post subject: Prop Strike crank damage Posted: Mon Nov 01, 2010 3:55 am Post subject: Prop Strike crank damage |

|

|

BJ,

Thanks for the good explanation for the purpose of the slipper clutch. Movement of the crank sections was not mentioned in my Rotax courses..(or that I remember) Makes perfect sense. Learn something new every day.

Sorry about the mis interpretation of "composite" as it applies to the crankshaft. Composite to me is like carbon fiber, kevlar,etc (ie; other than straight metal) Perhaps a sectional crankshaft or such would have been clearer. (ahhh yes...English)

Which brings me to the point:

We has a Rans S-6 flip upside down a few weeks ago during landing. It broke the Warp prop blades, oil temp housing,(sender broke the housing) and was at idle thrust. We replaced the housing,miked the shaft(OK) and still have the gearbox to check. I wonder if there could be a crank problem(ie: segment movement) or does in fact, the slipper clutch fully take care of that.

I have been on vacation so have not done any of the work myself

Dick Maddux

912UL

Milton,Fl

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Mon Nov 01, 2010 5:20 am Post subject: Prop Strike crank damage Posted: Mon Nov 01, 2010 5:20 am Post subject: Prop Strike crank damage |

|

|

Dick, Speaking of that English language bugaboo, did you mike the crank, i.e. check it's size with a micrometer, or indicate the crank, i.e. place a sensitive (resolution of .0001" or .005mm) dial indicator on the nose of the crank and check for runout as the crank is rotated? The latter is what is required after a prop strike, while the former is a nice to do but doesn't really tell you much unless there is evidence that the taper on the crank nose or the mating surface of the drive gear is damaged. See the Line Maintenance Manual, Section 5-50-00 "Unscheduled Maintenance" pages 3 and 4 and the Heavy Maintenance Manual Section 72-00-00, 3.18, pages 95 and 97.

Rick Girard

On Mon, Nov 1, 2010 at 6:52 AM, <Catz631(at)aol.com (Catz631(at)aol.com)> wrote:

| Quote: | BJ,

Thanks for the good explanation for the purpose of the slipper clutch. Movement of the crank sections was not mentioned in my Rotax courses..(or that I remember) Makes perfect sense. Learn something new every day.

Sorry about the mis interpretation of "composite" as it applies to the crankshaft. Composite to me is like carbon fiber, kevlar,etc (ie; other than straight metal) Perhaps a sectional crankshaft or such would have been clearer. (ahhh yes...English)

Which brings me to the point:

We has a Rans S-6 flip upside down a few weeks ago during landing. It broke the Warp prop blades, oil temp housing,(sender broke the housing) and was at idle thrust. We replaced the housing,miked the shaft(OK) and still have the gearbox to check. I wonder if there could be a crank problem(ie: segment movement) or does in fact, the slipper clutch fully take care of that.

I have been on vacation so have not done any of the work myself

Dick Maddux

912UL

Milton,Fl

| Quote: |

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

tp://forums.matronics.com

|

|

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

vernon11

Joined: 03 Aug 2010

Posts: 14

|

Posted: Mon Nov 01, 2010 5:52 am Post subject: Prop Strike crank damage Posted: Mon Nov 01, 2010 5:52 am Post subject: Prop Strike crank damage |

|

|

If There was any movement on the crank segments, how long would it take to show up on performance, or would it be noticable imediatly?

Vernon.

[quote] ---

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

Dick Maddux

Joined: 24 Jun 2008

Posts: 516

Location: Milton, Fl

|

Posted: Tue Nov 02, 2010 4:49 am Post subject: Prop Strike crank damage Posted: Tue Nov 02, 2010 4:49 am Post subject: Prop Strike crank damage |

|

|

Dick, Speaking of that English language bugaboo, did you mike the crank,

i.e. check it's size with a micrometer, or indicate the crank, i.e. place a

sensitive (resolution of .0001" or .005mm) dial indicator on the nose of the

crank and check for runout as the crank is rotated? The latter is what is

required after a prop strike, while the former is a nice to do but doesn't

really tell you much unless there is evidence that the taper on the crank

nose or the mating surface of the drive gear is damaged.

See the Line Maintenance Manual, <<

Rick

I just returned from vacation and was too pooped to talk let alone type! Too many errors.

No,a dial indicator was applied to the crank to determine the runout and it was fine, gearbox check will be next.(will use the manual as a guide)

Dick Maddux

912UL

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

KeysFox

Joined: 05 Jan 2009

Posts: 137

|

Posted: Tue Nov 02, 2010 2:06 pm Post subject: Prop Strike crank damage Posted: Tue Nov 02, 2010 2:06 pm Post subject: Prop Strike crank damage |

|

|

Try the Rotax technical help line at Lockwood Aviation in Sebring Florida and ask for the head of their Rotax shop Kerry for more details on rotation of the crank sections where they are press fit together caused by prop strike.That line is open for an hour in the am and an hour in the afternoon eastern time. Can't remember hours.They have a technique and equipment to measure the rotation or twist.Dean who runs the Rotax Institue did not bring it up.I suspect that the problem diagnosis and solution of crank shaft rotation at press fit junction is under scrutiny by Rotax and not out officially yet.My impressio was that the problem is primarily in non slipper clutch engines but not exclusively.B J N154K N626NR

Sent from my Verizon Wireless BlackBerryFrom: Catz631(at)aol.com

Sender: owner-rotaxengines-list-server(at)matronics.com

Date: Mon, 1 Nov 2010 07:52:57 -0400 (EDT)

To: <rotaxengines-list(at)matronics.com>

ReplyTo: rotaxengines-list(at)matronics.com

Subject: Re: RotaxEngines-List: Re: Prop Strike crank damage

BJ,

Thanks for the good explanation for the purpose of the slip= per clutch. Movement of the crank sections was not mentioned in my Rotax co= urses..(or that I remember) Makes perfect sense. Learn something new e= very day.

Sorry about the mis interpretation of "composite" as it applies = to the crankshaft. Composite to me is like carbon fiber, kevlar,etc (ie; ot= her than straight metal) Perhaps a sectional crankshaft or such would = have been clearer. (ahhh yes...English)

Which brings me to the point:

We has a Rans S-6 flip upside down a few weeks ago during landin= g. It broke the Warp prop blades, oil temp housing,(sender broke the housin= g) and was at idle thrust. We replaced the housing,miked the shaft(OK)= and still have the gearbox to check. I wonder if there could be a crank pr= oblem(ie: segment movement) or does in fact, the slipper clutch fully = take care of that.

I have been on vacation so have not done any of the work myself<= /DIV> &nbs= p; &= nbsp; &nbs= p; &= nbsp; Dick Maddux

&nbs= p; &= nbsp; &nbs= p; &= nbsp; 912UL

&nbs= p; &= nbsp; &nbs= p; &= nbsp; Milton,Fl

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

B Jones

N154K

443-480-1023 |

|

| Back to top |

|

|

KeysFox

Joined: 05 Jan 2009

Posts: 137

|

Posted: Wed Nov 03, 2010 9:38 am Post subject: Prop Strike crank damage Posted: Wed Nov 03, 2010 9:38 am Post subject: Prop Strike crank damage |

|

|

Re crank failure due to prop strike;

MY info is second hand and limited to what was in the eai posts.

Sorry.

BJ

Sent from my Verizon Wireless BlackBerry

--

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

B Jones

N154K

443-480-1023 |

|

| Back to top |

|

|

lucien

Joined: 03 Jun 2007

Posts: 721

Location: santa fe, NM

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Wed Nov 03, 2010 11:15 am Post subject: Prop Strike crank damage Posted: Wed Nov 03, 2010 11:15 am Post subject: Prop Strike crank damage |

|

|

Lucien, all, I don't think we're talking anything more than a few thousandths of an inch of twist out of register in the crank before significant damage happens to the main bearings. As you look at the crank you can see that the front and rear main bearing segments each carry a rod journal and the center main bearing segment carries a rod journal on each side. Connecting those three segments are essentially just plates. Now refer to Rotax table of limits for measuring the crank. First, it's done at the magneto drive end of the crank, not at the gearbox end and the 100% wear limit is only .0007" ( 7 ten thousandths of an inch ) over the maximum allowed for a brand new crank. Without splitting the case, what assumption would you have to make about any given movement of an individual crank segment? That movement most likely occurs at the plate connecting the crank nose and the center segments? Or does it reflect through all segments equally? For simplicity let's say all movement happens at the plate between rod journal 1 and 2 so that you get a reading of .0034" at the mag end and to further simplify all movement happens on rod journal 1. Even if you had a perfect, zero spec crank to start with, you are only talking .0017".

Measuring something at the top of the piston you'd have to decide how much, if any, variation could be accounted for by piston rock, wrist pin wear, rod journal wear, and rod bearing wear just to name a few. You could drive yourself nuts trying to factor in all those sources of measurement error, much less finding sine tables with enough accuracy to get measurement values and we haven't begun to think about movement caused by environmental factors not even related to the engine. Is the moon in the wrong position? Tide out or in?

Okay, I'm kidding with the last, but you get the idea.

Just to illustrate how difficult fine measurements like these can be, I have a precision level that I only use to set the bed of my engine lathe. It is so sensitive that the bubble will measure a change when I take a step. I cause the concrete pad on which the lathe sits to flex and the bubble moves. I don't drink coffee on the day I'm going to use it.

Rick Girard

On Wed, Nov 3, 2010 at 12:52 PM, lucien <lstavenhagen(at)hotmail.com (lstavenhagen(at)hotmail.com)> wrote:

| Quote: | --> RotaxEngines-List message posted by: "lucien" <lstavenhagen(at)hotmail.com (lstavenhagen(at)hotmail.com)>

I've always thought that a prop strike caused the "New Engine" light to come on in the panel....

Couldn't you tell if the journals had been twisted with a timing check? I.e. with a dial indicator put into the SP hole and a protractor on the crank?

Unless it was a new engine, I always figured a prop strike put you in the neighborhood of a new engine cost-wise anyway, so down to the bank... with a gun...

LS

--------

LS

Titan II SS

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=318055#318055

===========

="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

===========

http://forums.matronics.com

===========

|

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

| Description: |

|

| Filesize: |

309.38 KB |

| Viewed: |

13821 Time(s) |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|