|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Sep 26, 2022 11:49 am Post subject: AC current reading for Revmaster engine Posted: Mon Sep 26, 2022 11:49 am Post subject: AC current reading for Revmaster engine |

|

|

At 08:22 AM 9/25/2022, you wrote:

| Quote: | I will be monitoring the temps of the stator coils

and the voltage regulator. The voltage regulator I

will use will be the "John Deere type which I've

been told is the switching type. |

SERIES switching might be a more descriptive

term to distinguish it from the overwhelming

predominance of SWITCHING regulators that manage

energy in high frequency inductors/transformers.

| Quote: | I have been told by Revmaster that their regulator is the shunt type.

Unfortunately there seems to be no way of knowing for sure beforehand

what type of regulator a specific unit is. That information is

not included in any descriptions. |

I'm not sure that the voltage control philosophy

is terribly germane to your investigation. The

Revmaster community has predominately held that

alternator failures are closely associated with

loading of the alternator at or near maximum

output. This idea reinforced by suggestions

that batteries will particularly low internal

resistance are especially deleterious to

alternator service life.

When an alternator is heavily loaded

the shunting currents imposed by the regulator

are at a minimum. I.e. when heavily loaded,

stresses on the alternator are not

particularly driven by configuration of

regulator.

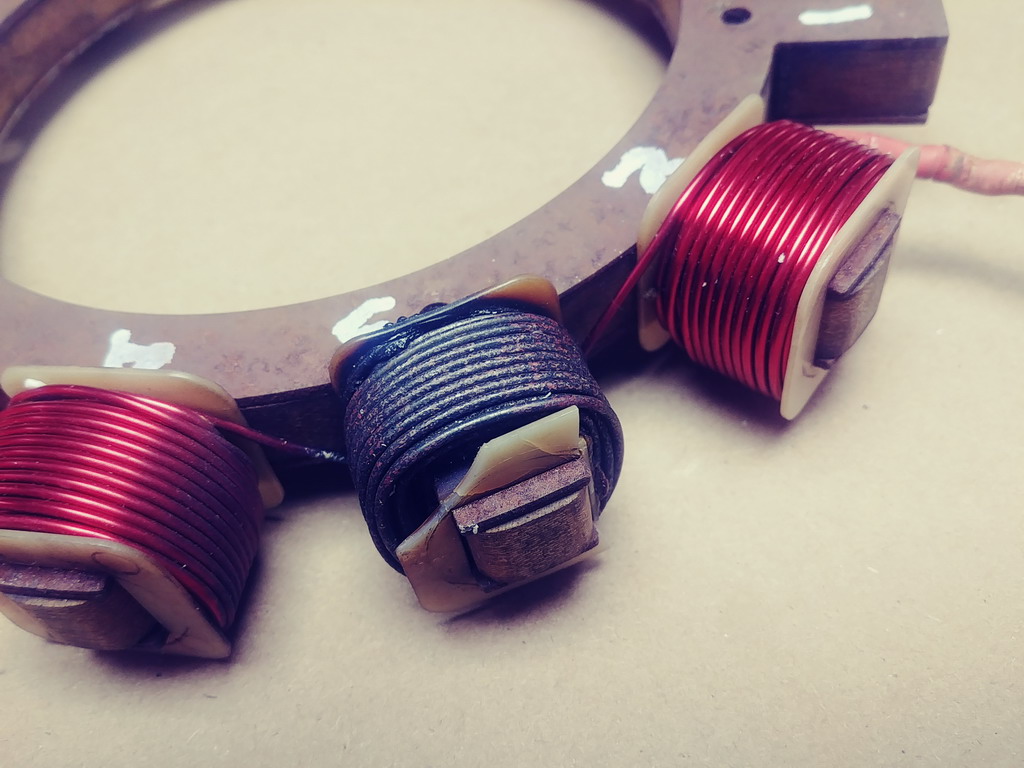

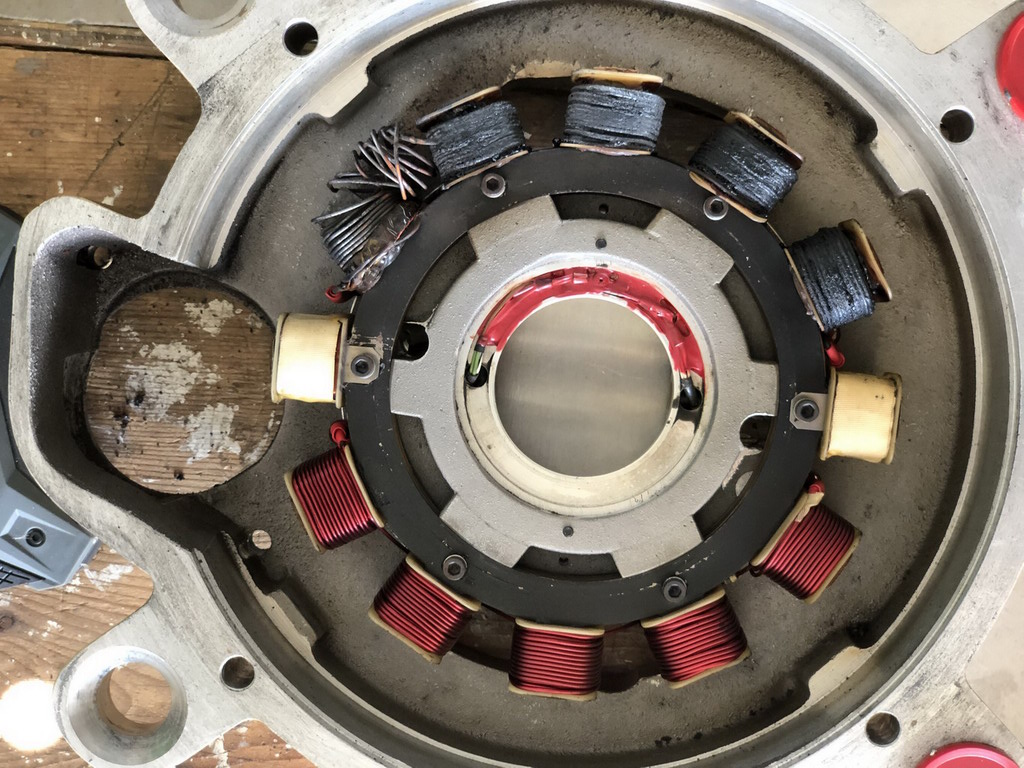

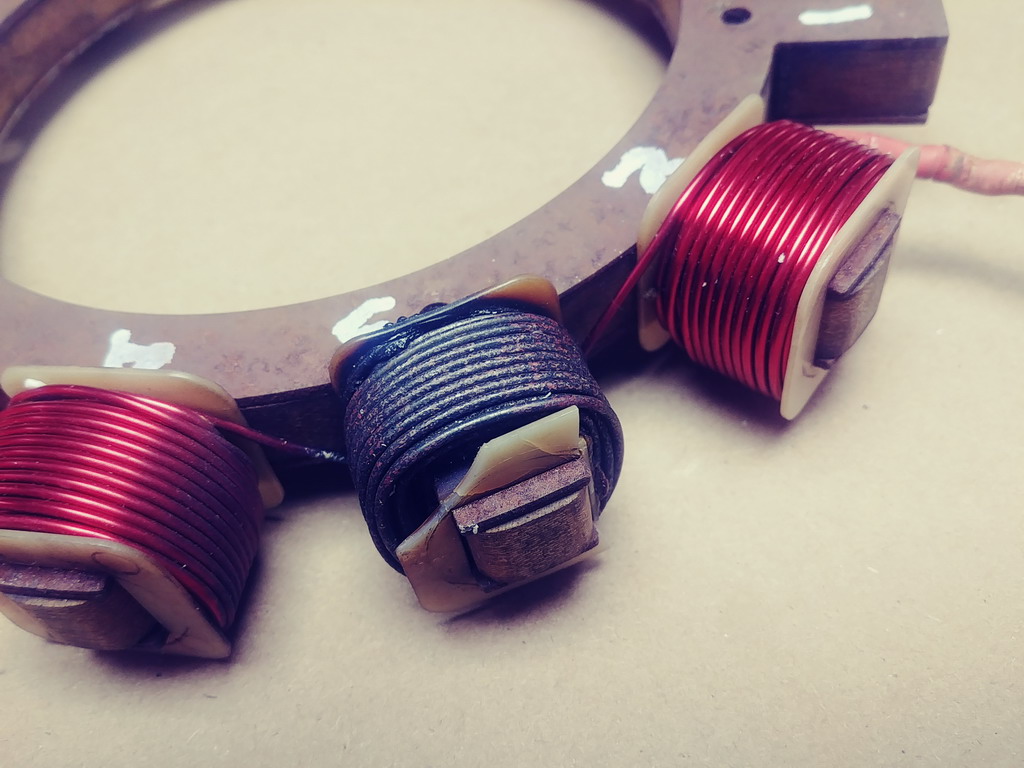

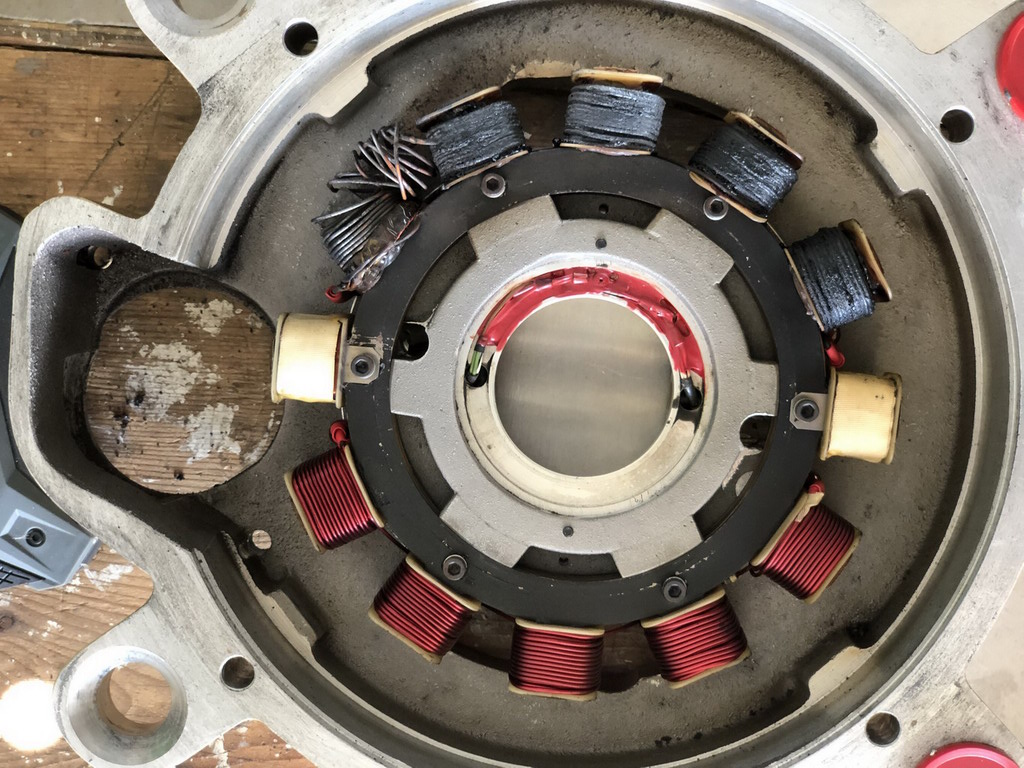

Another noteworthy feature of the failures I've

observed concerns the CONCENTRATION of overstress.

I've never personally encountered failed stator

on a rotating machine that did not present

uniform evidence of destruction over all

stator poles carrying that path of copper. We

see one such example in attached photo.

Some Revmaster alternators have tossed in the towel

after having toasted only one pole winding leaving

pristine poles on either side. But even the

illustration of total winding failure shows

one pole with much more damage than the rest.

I've seen assertions on the 'net describing

any combination of failures from single

pole to all poles.

It would be a real challenge to duplicate

a condition that replicates such a failure.

I'm reasonably certain that NO stress OUTSIDE

the alternator could produce such damage. Hence,

root cause is likely confined to INSIDE the

alternator.

Another curiosity arises with consideration

of the Revmaster PM alternator architecture.

The stator is wound with TWO separate windings

each of which drives a rectifier/regulator.

Either of the two windings is demonstrably

at risk for what seems to be an 'overload'

condition the magnitude of which is not numerically

defined but presumably considerably greater than

the factory's alternator power output ratings.

The Revmaster community has been thrashing about

looking for mitigation of failure while being

offered no methodology for quantifying and

guarding against such failures. Paul and Dan

are graciously volunteering to investigate the

cause/effect features and put numbers to them.

There have to be millions of exemplar alternator/

regulator/battery systems in everything from

mopeds to rather sophisticated heavier than

air machines. The physics for crafting such

systems having useful/satisfactory service life

is well understood.

Given my limited access to design decisions

and the totality of service history, I'm kinda

throwing darts here. But it seems that the

root cause for these failures is most likely

found in the MAGNETICS of the design as opposed

to any combination of electrics or environs. It

would be interesting to study the practicality

of fitting this engine with ONE alternator winding

of heavier wire spread over all stator poles

as opposed to TWO windings with demonstrably

fragile properties.

BTW . . . I've searched my library for a copy

of the R-2300 installation manual and came up

empty. Can anyone point me to a download link

or email me a copy?

| Quote: | | This charge system has (at least) 4 flaws. 1) low air flow/cooling. 2) erroneous stator design with magnetically saturated laminates. 3) no resin coating infusion on the windings |

Not sure that impregnation/coating of windings would

be terribly significant. This is a labor intensive

rare process in this arena. The net benefit would

be to spread heating effects more uniformly through

the winding mass but would not contribute to improved

cooling. At E-M our varnish impregnated windings were

treated mostly for improved resistance to moisture

and vibration than for thermal management.

| Quote: | 4) low air flow/cooling.

I injected DC current from a lab supply through the stator winding on the bench and measured the rise in temperature of the surface of the stator wire and the center laminate steel. I've concluded that continuous DC at 15 amps with an ambient temperature of 100 F will not create a temperature rise that is damaging (steady state of below 140 F). |

Not surprising. Temperatures required to 'toast' magnet

wire insulation are pretty severe. Back in my Electro-Mech

days, we slung a lot of magnet wire. We never used anything

less than 'class H' insulation . . . there was little to

be saved by going any lower. Most of our windings were

vacuum impregnated with a varnish and then baked. The

varnish was rated for temperatures equal to or greater than

the wire.

Another physical effect that may contribute to this

failure is tied to the temperature coefficient of resistance

for copper. This phenomenon has been studied in great

detail and accurately know for a very long time.

https://tinyurl.com/p2sjmhtn

As an practical/observable matter

Temperature rating for insulation does is not fall-off-

the-edge-of-the-earth limit. This paper speaks

to a temperature vs. service life for various insulations

https://tinyurl.com/2e7z7wwx

Class H insulation is qualified to function at rated temperature

limits for 20,000 hours with that number falling by 1/2 for

each 10 degree C increase.

Temperatures that toast the wires in one stator pole

while leaving adjacent poles relatively untouched

have to have a profound and probably very simple

explanation.

| Quote: | | Increasing air flow is job 1, wrt cooling this stator. Impregnating the wiring is an improvement that I advocate but do not have data on it. My direct conversation with the stator wire manufacturer, and their recommendation suggests to me it would be an improvement. |

Did they quantify 'improvement'?

To quote a rather intelligent fellow of some years past:

Can you measure it? Can you express it in figures?

Can you make a model of it? If not, your theory

is apt to be based more upon imagination than upon

knowledge. === Lord Kelvin ===

| Quote: | | I can share the method of impregnating the stator wiring that I'm using with the webŁ, but I'm reluctant to advertise this until I can verify there is no damage to the ignition coils. I've tested impregnation on the stator coils but the locally mounted ignition coil wire is different (much smaller and from an unknown supplier). |

It seems unlikely that the insulation will be any less

robust

Bob . . .

Un impeachable logic: George Carlin asked, "If black boxes

survive crashes, why don't they make the whole airplane

out of that stuff?"

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

162.6 KB |

| Viewed: |

1508 Time(s) |

|

| Description: |

|

| Filesize: |

266.01 KB |

| Viewed: |

1508 Time(s) |

|

|

|

| Back to top |

|

|

dj_theis

Joined: 28 Aug 2017

Posts: 56

Location: Minnesota

|

Posted: Tue Sep 27, 2022 6:38 pm Post subject: Re: AC current reading for Revmaster engine Posted: Tue Sep 27, 2022 6:38 pm Post subject: Re: AC current reading for Revmaster engine |

|

|

| Quote: | Quote:

Increasing air flow is job 1, wrt cooling this stator. Impregnating the wiring is an improvement that I advocate but do not have data on it. My direct conversation with the stator wire manufacturer, and their recommendation suggests to me it would be an improvement.

Did they quantify 'improvement'? |

Good point.

The conversation was a follow up of my question, "what is the temperature rating of the magnet wire being used."

His response was that the coating was "designed to be soldered without direct abrasive removal of the insluation." (i.e. the heat from soldering would remove the insulation.). From memory, his suggestion was that the wire should be coated to achieve the desired insulation temperature rating. No specific level of improvement was defined other than the implicit message that the wire was not designed to be left uncoated in this type of an application.

It's likely that leaving the wire uncoated does not guarantee failure. I would guess that many or most of the stators don't fail. I don't have statistic on the failure rate of this design.

It's evident that the unusual localized heating that we've seen (and you show in the attachment) is suggestive of a very unusual heat source.

I've been kicking this around for a while and it recently occurred to me that perhaps some of localized coil failure is a result of the single phase regulator \ rectifier (that is little more than an SCR) going through a catastrophic failure as a short. this would provide the full current from the battery to feed back through the stator, at least until one of the 30 amp fuses blow.

I don't think there is any other power source other than the battery, available to cause so much damage as we see on some of these stators. It also might explain a single coil buring up. As you've often brought up, an open wire will melt at a spot somewhere in the middle. Has anyone ran a short circuit test on a multi-coil stator like this? Would it not make some sense that one isolated coil could go through the rapid rise in resistance and burn up before the rest?

Attached is the charge circuit as I believe it is with the OEM regulator. I've added an overvoltage relay but I think we can ignore that component from the discussion.

Thoughts?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

Revmaster 2300 rev13 alternator ckt.pdf |

| Filesize: |

63.23 KB |

| Downloaded: |

114 Time(s) |

_________________

Dan Theis

Scratch building Sonex #1362

Still working on the Revmaster Alternator improvement |

|

| Back to top |

|

|

dj_theis

Joined: 28 Aug 2017

Posts: 56

Location: Minnesota

|

Posted: Tue Sep 27, 2022 6:45 pm Post subject: Re: AC current reading for Revmaster engine Posted: Tue Sep 27, 2022 6:45 pm Post subject: Re: AC current reading for Revmaster engine |

|

|

| Quote: | BTW . . . I've searched my library for a copy

of the R-2300 installation manual and came up

empty. Can anyone point me to a download link

or email me a copy? |

Attached is the "Electrical" portion of the Revmaster manual.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

Revmatser R-2300 Manual C - CDI Electrical.pdf |

| Filesize: |

1.38 MB |

| Downloaded: |

104 Time(s) |

_________________

Dan Theis

Scratch building Sonex #1362

Still working on the Revmaster Alternator improvement |

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1908

Location: Riley TWP Michigan

|

Posted: Wed Sep 28, 2022 7:34 am Post subject: Re: AC current reading for Revmaster engine Posted: Wed Sep 28, 2022 7:34 am Post subject: Re: AC current reading for Revmaster engine |

|

|

Dan,

Your theory about battery current destroying the dynamo coils makes sense.

If correct, then I can think of a couple of solutions.

1. Replace the 30 amp fuses with 20 amp ones. And limit the aircraft load to 15 amps. If the regulator shorts out, then a fuse will blow.

2. Put a Schottky diode in series with the voltage regulator output. If the regulator shorts out, the diode will block battery current.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Sep 28, 2022 6:24 pm Post subject: AC current reading for Revmaster engine Posted: Wed Sep 28, 2022 6:24 pm Post subject: AC current reading for Revmaster engine |

|

|

| Quote: | The conversation was a follow up of my question, "what is the temperature rating of the magnet wire being used."

His response was that the coating was "designed to be soldered without direct abrasive removal of the insluation." (i.e. the heat from soldering would remove the insulation.). From memory, his suggestion was that the wire should be coated to achieve the desired insulation temperature rating. No specific level of improvement was defined other than the implicit message that the wire was not designed to be left uncoated in this type of an application. |

This style of insulation on magnet wire

is primarily intended for the electronics

industry . . . the winding of inductors,

signal transformers. Used to buy the stuff

under the 'SolderEze' brand about 30 years

ago. Here's a contemporary example:

https://essexfurukawa.com/products/soderon-155-cu/product-datasheet/product-datasheet

63/37 solder is liquid at about 190C/333F.

Working temperature of tools would be set

for 220C or thereabouts. Other alloys of

solder would be higher.

The exemplar wire is rated at 155C . . . at

which some service life is expected. Usually

some tens of thousands of hours . . . with

an expected depression of 1/2 for each

10C rise in temperature.

So without having specific data on the

wire in question, we can safely assume

that operation at 350F is not a severe

stress on the wire. Class H insulation

is rated at 180C. So while this solderable

wire is not Class H, it's not terribly

fragile either.

| Quote: | It's evident that the unusual localized heating that

we've seen (and you show in the attachment) is suggestive

of a very unusual heat source. |

Precisely

| Quote: | I don't think there is any other power source other than the battery,

available to cause so much damage as we see on some of these stators.

It also might explain a single coil buring up. As you've often brought up,

an open wire will melt at a spot somewhere in the middle. |

Yes, hanging out in free air where the

temperature coefficient of resistance

for copper creates a potential failure

location with heat energy fed from both

directions exacerbated by increase

in resistance.

It may well be that one winding on the

stator is singled out by a temperature

condition much higher than adjacent

poles but given the heat-sinking effect

of the stator iron, a melts-in-the-center

effect seems unlikely.

I'm still fond of the notion that faileded

windings get a thermal boost NOT from

I(squared)R losses in the wire but from

Eddy current losses in the iron on which

the wire is wound.

| Quote: | Has anyone ran a short circuit test on a multi-coil stator

like this? Would it not make some sense that one isolated

coil could go through the rapid rise in resistance and burn

up before the rest? |

Not able to wrap my head around this idea.

I'm still thinking root cause is in the

poorly crafted magnetics. External forces

such as system loads and style of regulator

are secondary and much less influential.

Bob . . .

Un impeachable logic: George Carlin asked, "If black boxes

survive crashes, why don't they make the whole airplane

out of that stuff?"

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|