|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

PCahill

Joined: 05 Feb 2018

Posts: 6

|

Posted: Sat Mar 20, 2021 3:00 pm Post subject: 914 Servo Problem -- broken copper wiper -- is there a fix? Posted: Sat Mar 20, 2021 3:00 pm Post subject: 914 Servo Problem -- broken copper wiper -- is there a fix? |

|

|

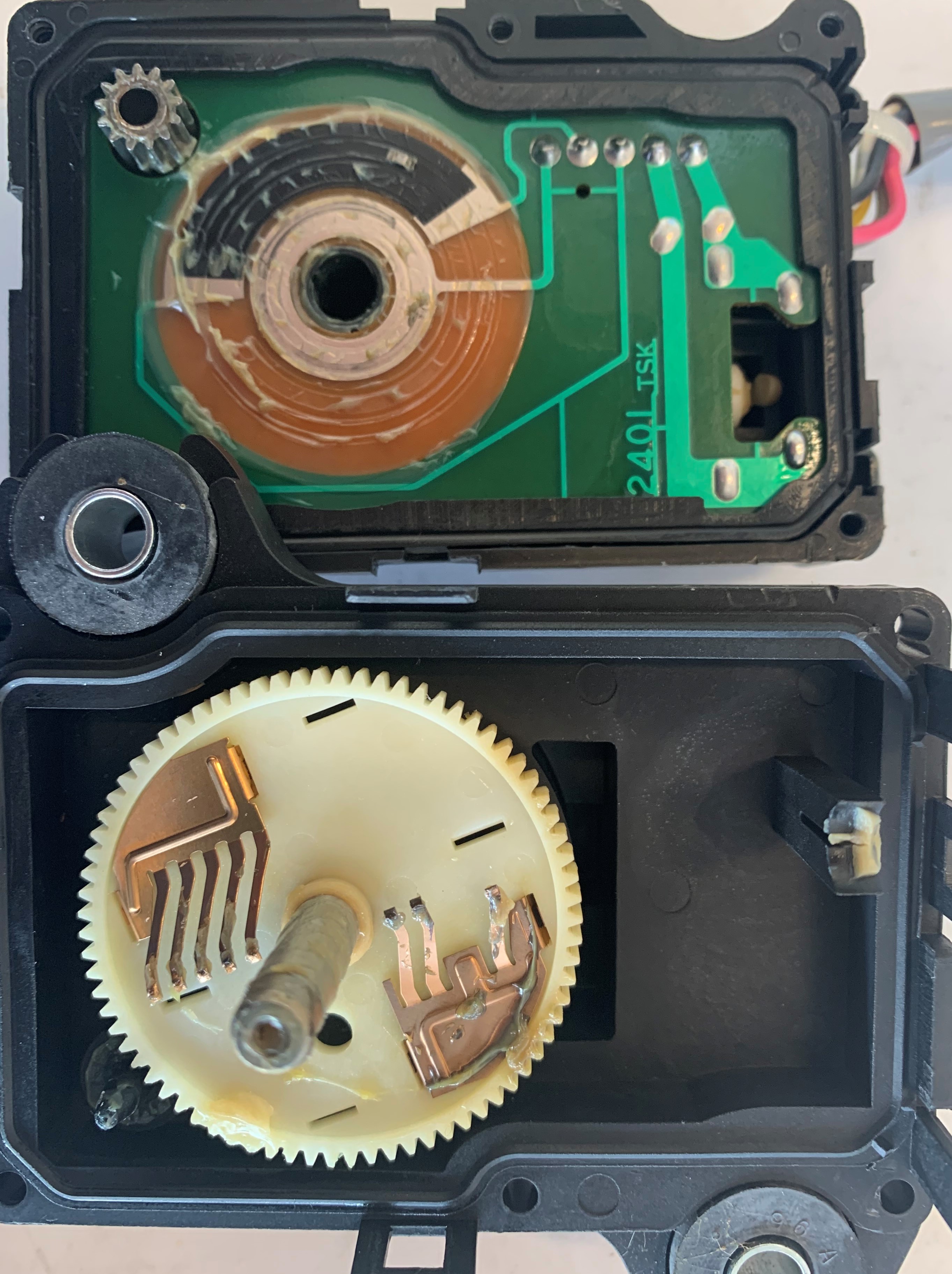

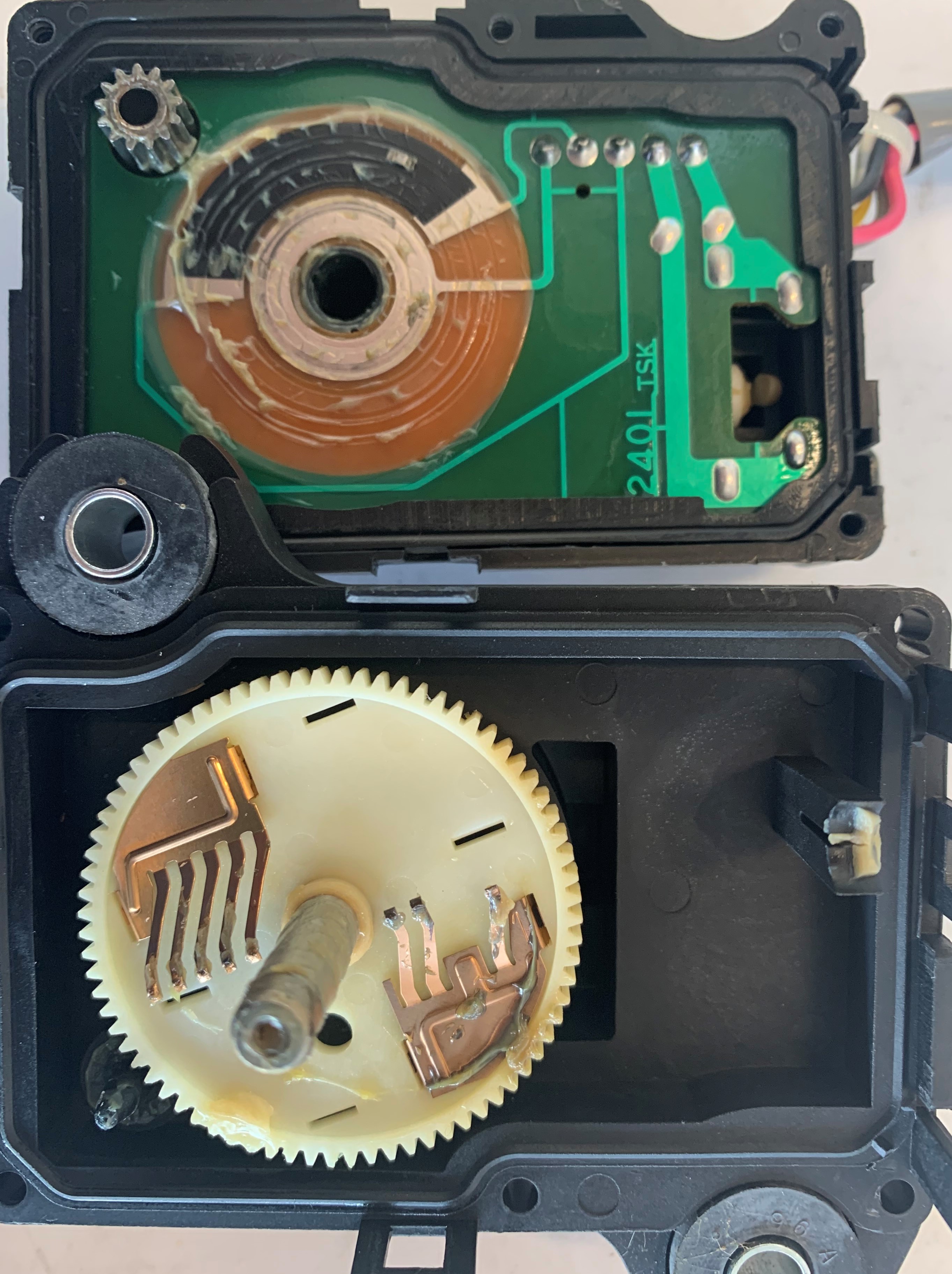

The picture shows the inside of my TCU wastegate servo where the tip of one wiper has broken off and is now stuck against (perhaps with dielectric grease) what appears to be a screen printed resistor that is used by the TCU to measure servo position.

The symptom was a jammed wastegate cable and a blinking orange TCU light that appears about 6 seconds after power up (not immediately like what happens with a disconnected sensor). After I removed the jammed cable from the servo wheel, the servo rotates "too far" on power-up -- clockwise past the cable mount before returning to the start position. No wonder the servo and cable were jammed. When I opened the servo, the broken copper wiper was obvious.

Has anyone else seen this? Can I buy a gear with the copper wipers, or maybe just the wipers themselves? This happened suddenly: 2 weekends ago everything was perfect, last weekend -- blinking light. This weekend -- disassemble until problem found. I can't imagine that I'm the only one with what amounts to a potentiometer with a bad wiper. This is certainly not a $500 failure (cost of new servo). Thanks.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

N914TX |

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 780

|

Posted: Sat Mar 20, 2021 4:01 pm Post subject: Re: 914 Servo Problem -- broken copper wiper -- is there a f Posted: Sat Mar 20, 2021 4:01 pm Post subject: Re: 914 Servo Problem -- broken copper wiper -- is there a f |

|

|

Hi PCahill Your picture didn't come through. I took a look and page 50 and 51 of Heavy Maintenance 76-00-00 https://www.cps-parts.com/cps/pdf/d05014.pdf gives value of potentiometer you need to know.

I would call Rotax Center and see if they can get parts, if not can they rebuild it for you?

Perhaps you can locate a good used one? I did a quick search and found:

https://www.ebay.com/p/10008622325

I don't know what the thing looks like, but you know the values from the manual, perhaps you can buy the part? Look at big 4? Mouser, Allied, Newark and Digi-key.

Since you know the values, perhaps you can rig up an external potentiometer. Perhaps you could drive off cable if it has correct throw? If not turn a barrel the precise diameter and drive a cable? Or make a servo arm the precise length?

I ran into a problem with my cowl flap. The Actonix linear servo had an internal potentiometer. I purchased their display that has a severe design flaw and after 2 attempts burned up internal wiring to potentiometer. I ended up installing a Ray Allen external potentiometer to one of their displays. Works great: http://www.rayallencompany.com/products/indsens.html they call it a position sensor. This is to give you an idea to use an external position sensor.

I took Buds advise and have the cable tail of my Servo follow on into a piece of plastic tube:

https://1drv.ms/u/s!Ah1S270Nwg9V3UQweNiOl3_VYcum

If you could match the required values using a long tail to drive position sensor, could be very nice. You could probably trim values a little with resistors. If not lucky, obtaining a sensor with correct values and making a barrel with precise diameter needed to drive a cable would probably be my second choice.

Here's a pic of install of external sensor on my cowl flap:

https://1drv.ms/u/s!Ah1S270Nwg9V3HM-hjioId6wjy9L

sensor on left side. I needed to position the pin a precise distance from flap pivot. Works great (on ground thus far). BTW the cowl flap closes 100% and opens with trail edge hanging down in airstream about same angle as my old 1948 Cessna 170 had aft side of cowl hanging in breeze:

https://1drv.ms/u/s!Ah1S270Nwg9V2HOfKEwvGS64xgPO

Ron P.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

PCahill

Joined: 05 Feb 2018

Posts: 6

|

Posted: Sat Mar 20, 2021 4:26 pm Post subject: Re: 914 Servo Problem -- broken copper wiper -- is there a f Posted: Sat Mar 20, 2021 4:26 pm Post subject: Re: 914 Servo Problem -- broken copper wiper -- is there a f |

|

|

Photo didn't attach on first try

Also posted to Rotax-Owner -- photo ok there

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

| photo cropped - original too big |

|

| Filesize: |

1.58 MB |

| Viewed: |

2235 Time(s) |

|

_________________

N914TX |

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 780

|

Posted: Sat Mar 20, 2021 5:32 pm Post subject: Re: 914 Servo Problem -- broken copper wiper -- is there a f Posted: Sat Mar 20, 2021 5:32 pm Post subject: Re: 914 Servo Problem -- broken copper wiper -- is there a f |

|

|

Hi PCahill Now that I have seen the unit and heard from Bud a few ideas:

Ask Bud if he still has his old unit that may have a good set of brushes on gear and buy it from him and put on your unit? Note: There may be different variations of servo, I have no ideas what the differences are. Perhaps the gear/brushes is the same?

Measure the thickness of copper on brush, procure same or similar from McMaster or other:

https://www.mcmaster.com/copper-sheets

Cut off a good portion of remaining leg on broken brush and form the end to look exactly like other brushes, then solder splice a piece of copper splint.

I would probably do the percussive maintenance trick on solder job. Take some of the thinnest solder you can find, then pound it into a thin sheet and cut to precise size of splint. Put some flux on both sides after cleaning copper immaculate and make a few clamps to hold it in position. Use some thin SS welding rod if you have it, if not bend up some paper clips. Start with a modified Omega shape. Thy different sizes of clamp also different thickness paper clips or welding rod. If you have a problem getting heat in there or getting your soldering iron in position, use flame from cigarette lighter. I would wrap neighboring brushes with a piece of aluminium foil to keep heat off them. we don't know what sort of temper they may have.

You ultimately want about the same pressure on brush as others. Since you are splicing and may not be using the exact same copper, you will probably end up a bit stiffer? If that happens you can probably do like Shunts do. Start making the width a little bit narrower at a time till pressure is the same.

If you need more tension, beat a piece3 of copper thinner, cut to size and splint.

Look very careful at other brushes for any cracks. Any defects smooth out.

Look very very carefully at the broken pieces and see if there is a defect that caused a stress riser. If there is, perhaps contact Rotax and see if they can be of assistance. Probably out of warranty, but since it was definitely a factory defect, it would be greatly appreciated if they could help you out, like 50 to 75% discount off replacement? Good luck on that one

Ron P.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|