|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

kingsnjan(at)westnet.com.

Guest

|

Posted: Wed Dec 11, 2019 9:24 pm Post subject: Hacman Gen 3 Mixture Control Posted: Wed Dec 11, 2019 9:24 pm Post subject: Hacman Gen 3 Mixture Control |

|

|

Group,

Does anybody have any experience with the Hacman Gen 3 Mixture Control

on their 912 or 912S please?

Reason is that I am astounded how much more fuel my 912 (80 HP) burns at

altitude than when low down. eg. At altitude where the MAP is say 20"

at wide open throttle and 5000 rpm, the fuel flow is 17-18 LPH while on

the same power setting (20" and 5000 rpm) at 2500 ft, the fuel flow is

12-13 LPH. I have discovered that at altitude with WOT, if I throttle

back until the MAP "just" starts to drop, the fuel flow will drop back

approx 1 LPH.

If the Hacman unit works, I am interested in procuring one.

Many thanks

Kingsley from Oz

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Remi Guerner

Joined: 14 Dec 2010

Posts: 284

|

Posted: Thu Dec 12, 2019 2:11 am Post subject: Re: Hacman Gen 3 Mixture Control Posted: Thu Dec 12, 2019 2:11 am Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

Hello Kingsley,

One reason for a higher fuel flow at altitude for the same MAP and RPM is that your engine is developing more power. Taking your example, full throttle/20" means you are at around 10000 ft. At this altitude, the outside temp is minus 4,5°C (standard atmosphere) This is almost 20°C less than at sea level. Then your engine is developing 7% more power (293/273). The Rotax runs richer at altitude. Based on my experience, this over rich mixture increases the fuel consumption about 10% at 10000ft compared to low altitude at the same power. You say your fuel flow is 40% higher: that is surprising and I assume your flow meter is not accurate.

I do not have any experience with the Hacman, but I have done some testing on my 912ULS with my own mixture system (using an electric pump to suck pressure out of the carb bowl vents). The system worked fine, was fail safe, but there was no power gain at full throttle at altitude. This was disappointing and I decided that the possible 10% fuel saving was not worth the additional complexity.

Remi

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 780

|

Posted: Thu Dec 12, 2019 12:42 pm Post subject: Re: Hacman Gen 3 Mixture Control Posted: Thu Dec 12, 2019 12:42 pm Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

Hi Kingsley

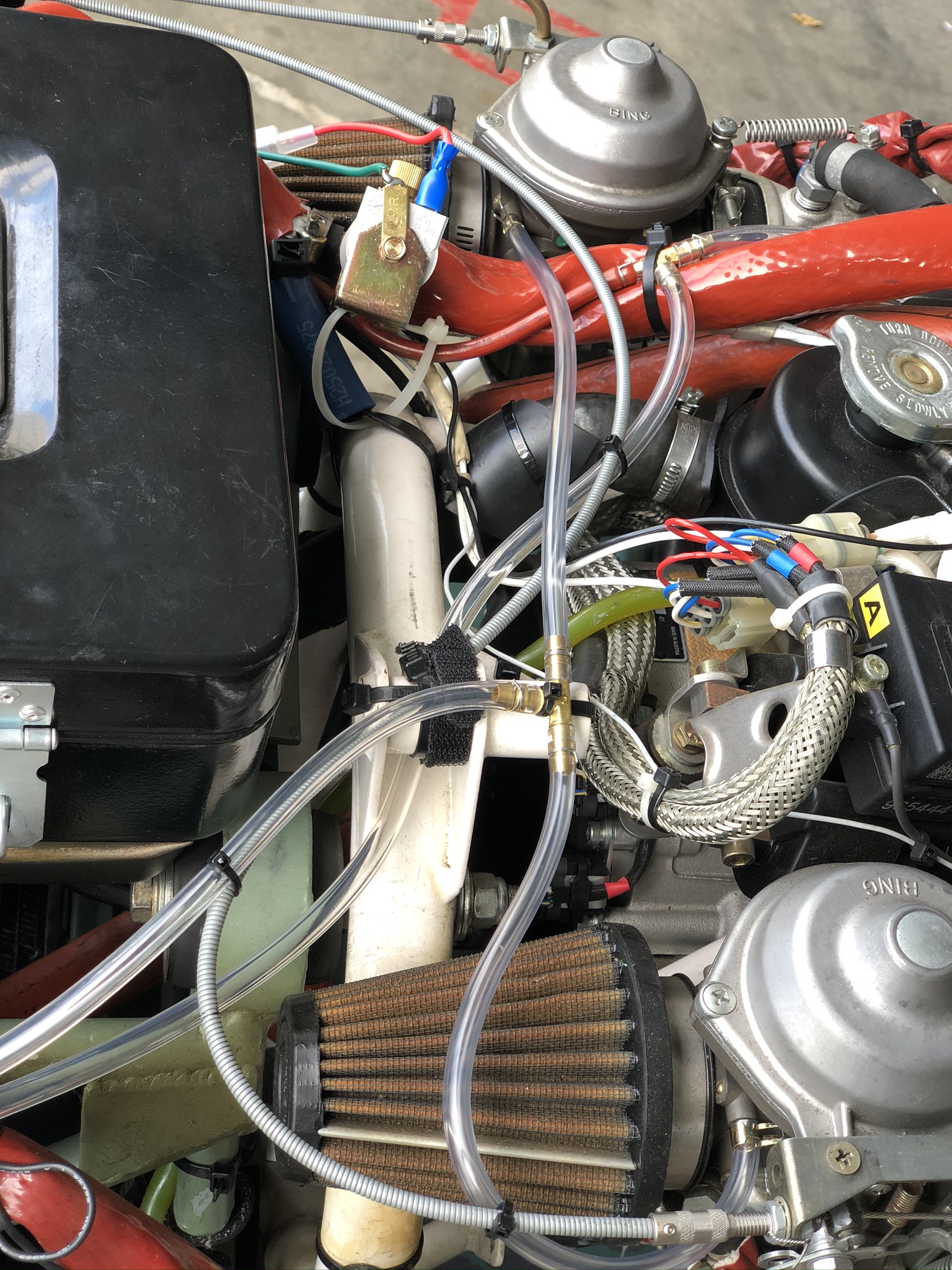

Carburetors mix fuel to air by volume of air. Going up in altitude decreases the number of air molecules per given volume of air a lot more than the decrease in temperature. Thus since there are less air molecules for a given amount of fuel the mixture will be richer than optimal. I will speak general but often full throttle will provide a richer mixture than less than full throttle. The reason is to cool the fire by throwing more gas on it! I have a 914 which complicates the life of the poor Bing type 64 constant depression carbs but am installing a Hacman that will work on the 914. Have not yet tested but should be fine. Mind you if you have control of mixture it can be a good thing, but if you run hard and lean that can be a terrible thing. If you lean at altitude when you come down or pull the throttle it will be leaner than desirable so you will need to add this extra bit to your piloting tasks.

see Mixture 1 and 2

http://www.europaowners.org/main.php?g2_itemId=27305&g2_page=2

I am installing 2 EGTs and a Split Second monitor. It uses a O2 sensor to drive it. It allows you to monitor mixture. Unlike a fuel injection system that needs very fast response time of the O2 sensor, using one in this capacity only needs a very slow response time. Thus even using Leaded Fuel, should be able to get 100 hours out of O2 sensor from what I'm told.

Ron P.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

kingsnjan(at)westnet.com.

Guest

|

Posted: Sat Dec 14, 2019 3:25 am Post subject: Hacman Gen 3 Mixture Control Posted: Sat Dec 14, 2019 3:25 am Post subject: Hacman Gen 3 Mixture Control |

|

|

Hello Remi,

Thank you for your input which as usual, I appreciate.

I hadn't considered the effect of lower temperature at altitude but do

understand your reasoning albeit our temps are a far cry from yours. At

the moment, freezing level is above 10,000 ft. Regarding my fuel flow

meter, I do keep impeccable records of fuel used and my totalizer is

very accurate. I therefore have no reason to doubt the accuracy of the

flow meter.

In my quest for a better understanding of Bing carbs and there

idiosyncrasies, if you have any info available which you would be

prepared to share on your leaning system Remi, I would very much

appreciate same please.

Thanks again

Kingsley

On 12.12.19 8:11 pm, Remi Guerner wrote:

| Quote: |

Hello Kingsley,

One reason for a higher fuel flow at altitude for the same MAP and RPM is that your engine is developing more power. Taking your example, full throttle/20" means you are at around 10000 ft. At this altitude, the outside temp is minus 4,5°C (standard atmosphere) This is almost 20°C less than at sea level. Then your engine is developing 7% more power (293/273). The Rotax runs richer at altitude. Based on my experience, this over rich mixture increases the fuel consumption about 10% at 10000ft compared to low altitude at the same power. You say your fuel flow is 40% higher: that is surprising and I assume your flow meter is not accurate.

I do not have any experience with the Hacman, but I have done some testing on my 912ULS with my own mixture system (using an electric pump to suck pressure out of the carb bowl vents). The system worked fine, was fail safe, but there was no power gain at full throttle at altitude. This was disappointing and I decided that the possible 10% fuel saving was not worth the additional complexity.

Remi

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

kingsnjan(at)westnet.com.

Guest

|

Posted: Sat Dec 14, 2019 3:58 am Post subject: Hacman Gen 3 Mixture Control Posted: Sat Dec 14, 2019 3:58 am Post subject: Hacman Gen 3 Mixture Control |

|

|

Thanks Ron,

You say, "full throttle will provide a richer mixture". From my

experience in a previous life flying aircraft with mixture controls, I

understand that a richer mixture on full throttle is usually the result

of the Power Jet. To my knowledge, the Bing Carb has no power jet.

As I alluded to in another post, it appears to me that the lack of

pressure differential across the butterfly valve on the Bing, causes the

mixture needle to rise, enriching the mixture and effectively acting

like the power jet on GA aircraft type carbs. The difference between

the GA type carbs and the Bing then being that the GA ones can be

manually leaned.

looking forward to hearing of your first flight Ron.

Kingsley

On 13.12.19 6:42 am, rparigoris wrote:

| Quote: |

Hi Kingsley

Carburetors mix fuel to air by volume of air. Going up in altitude decreases the number of air molecules per given volume of air a lot more than the decrease in temperature. Thus since there are less air molecules for a given amount of fuel the mixture will be richer than optimal. I will speak general but often full throttle will provide a richer mixture than less than full throttle. The reason is to cool the fire by throwing more gas on it! I have a 914 which complicates the life of the poor Bing type 64 constant depression carbs but am installing a Hacman that will work on the 914. Have not yet tested but should be fine. Mind you if you have control of mixture it can be a good thing, but if you run hard and lean that can be a terrible thing. If you lean at altitude when you come down or pull the throttle it will be leaner than desirable so you will need to add this extra bit to your piloting tasks.

see Mixture 1 and 2

http://www.europaowners.org/main.php?g2_itemId=27305&g2_page=2

I am installing 2 EGTs and a Split Second monitor. It uses a O2 sensor to drive it. It allows you to monitor mixture. Unlike a fuel injection system that needs very fast response time of the O2 sensor, using one in this capacity only needs a very slow response time. Thus even using Leaded Fuel, should be able to get 100 hours out of O2 sensor from what I'm told.

Ron P.

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Remi Guerner

Joined: 14 Dec 2010

Posts: 284

|

Posted: Tue Dec 17, 2019 7:29 am Post subject: Re: Hacman Gen 3 Mixture Control Posted: Tue Dec 17, 2019 7:29 am Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

"if you have any info available which you would be

prepared to share on your leaning system Remi, I would very much

appreciate same please. "

Hello Kingsley,

First I want to say that I am not the inventor off the principle of creating a vacuum in the float bowl using an electric pump to lean the Bing carbs. This leaning device was designed about 20 years ago by Michel Colomban, designer of the Cri-Cri and MC100 on which the well known DynAero MCR series were based. He designed his own pump to create the vacuum. The vacuum is adjusted through a potentiometer and the mixture ratio is measured using an O2/ lambda probe. Attached are some original Colomban's drawings (in French, sorry)

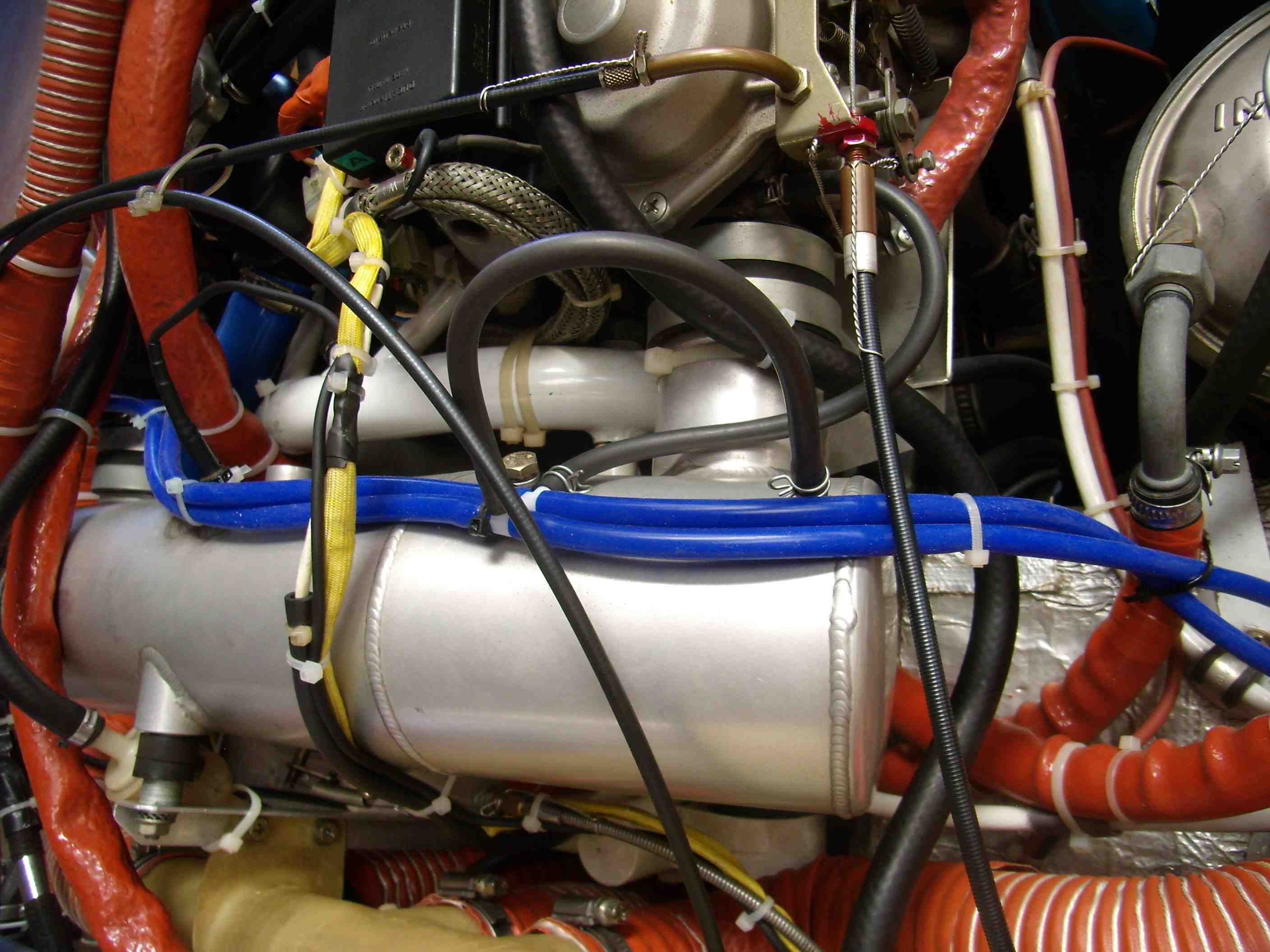

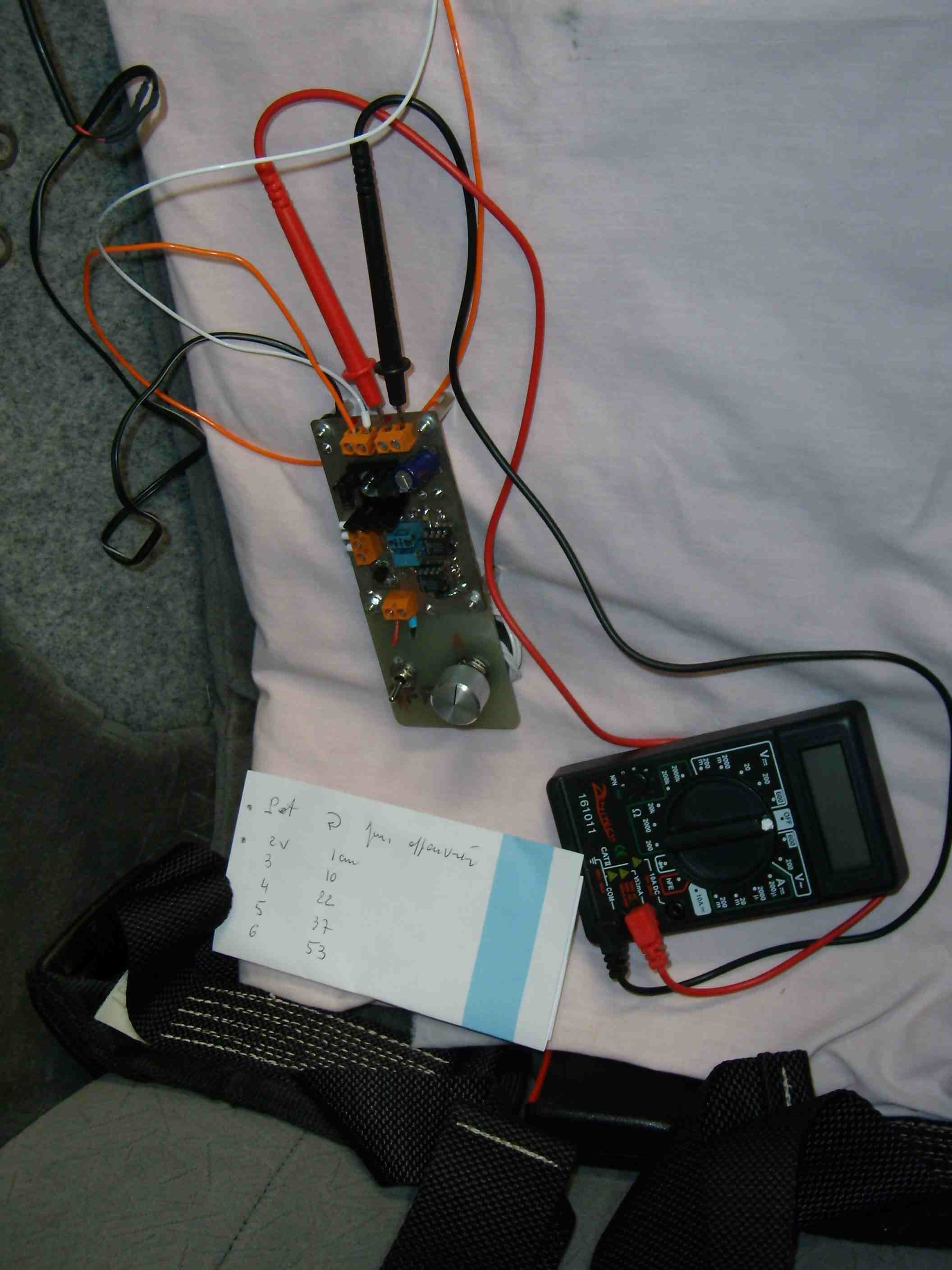

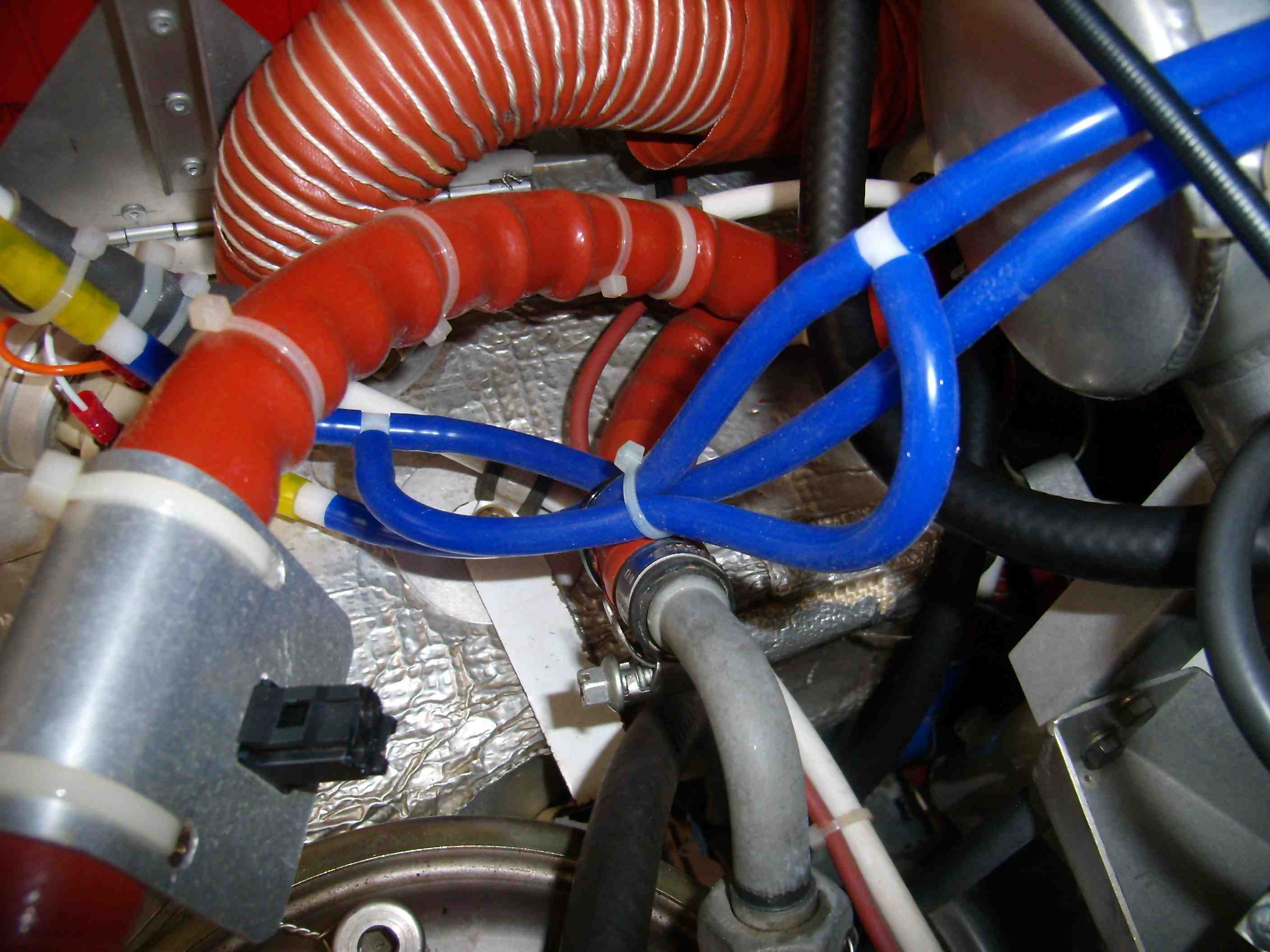

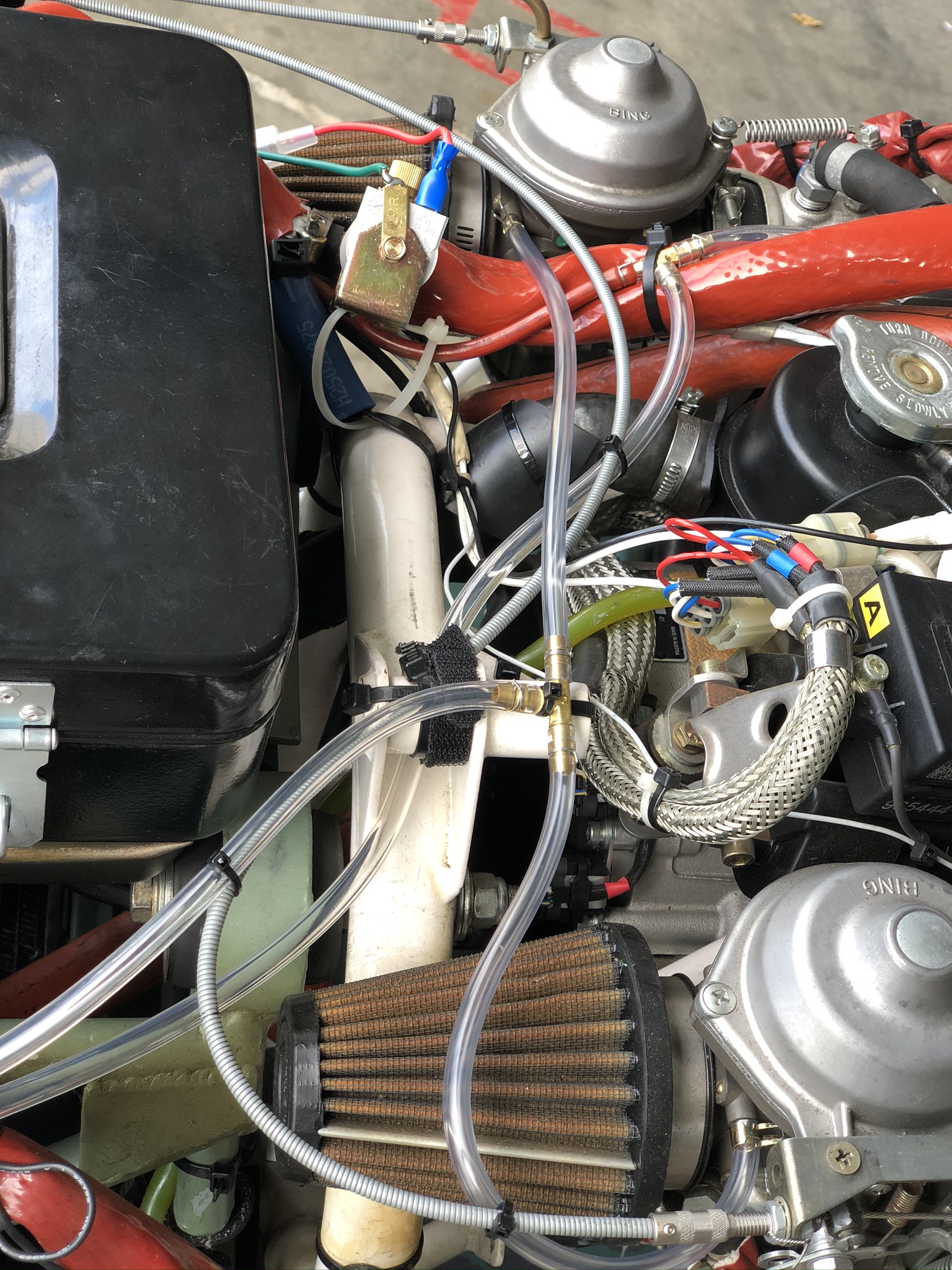

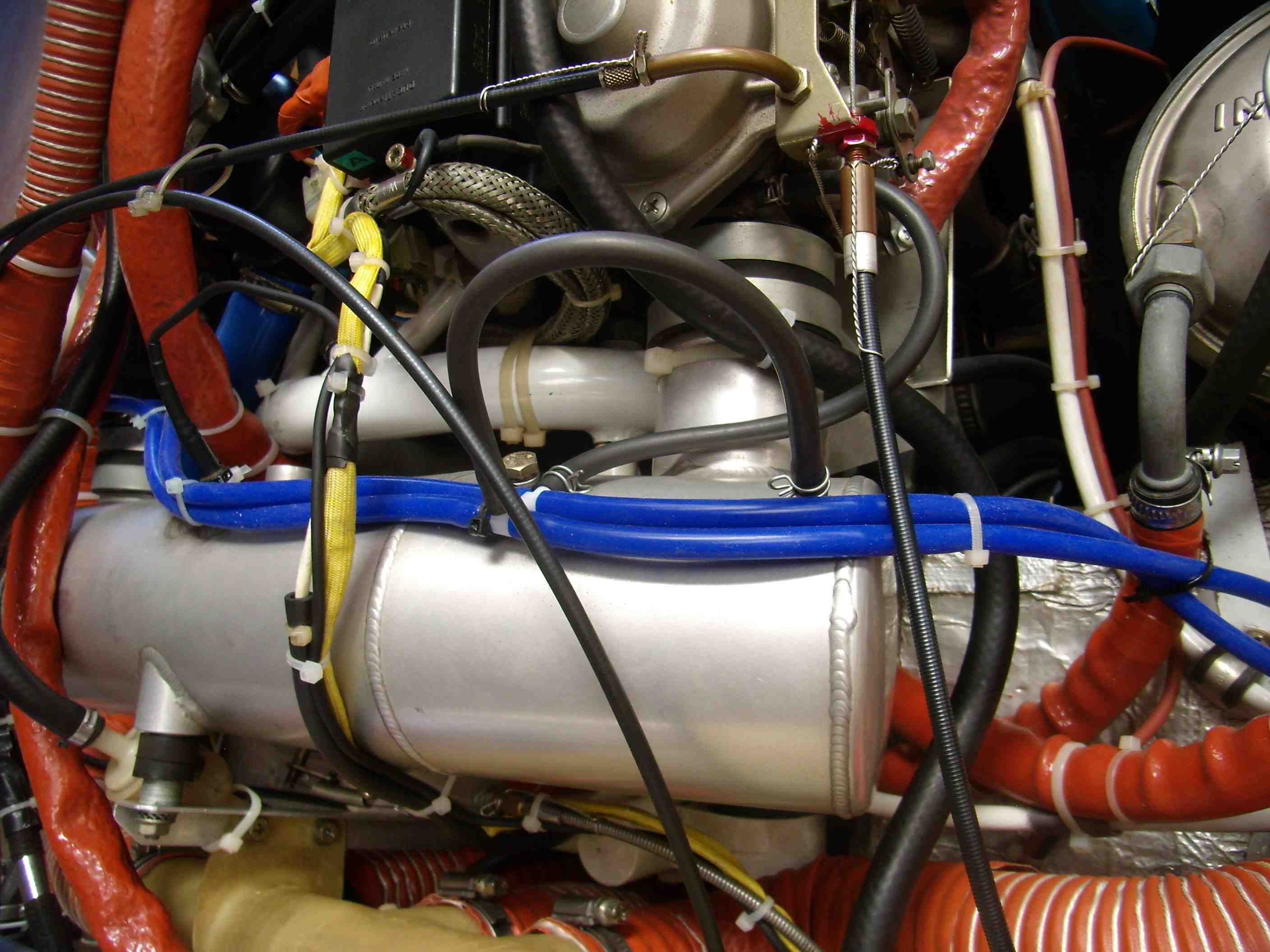

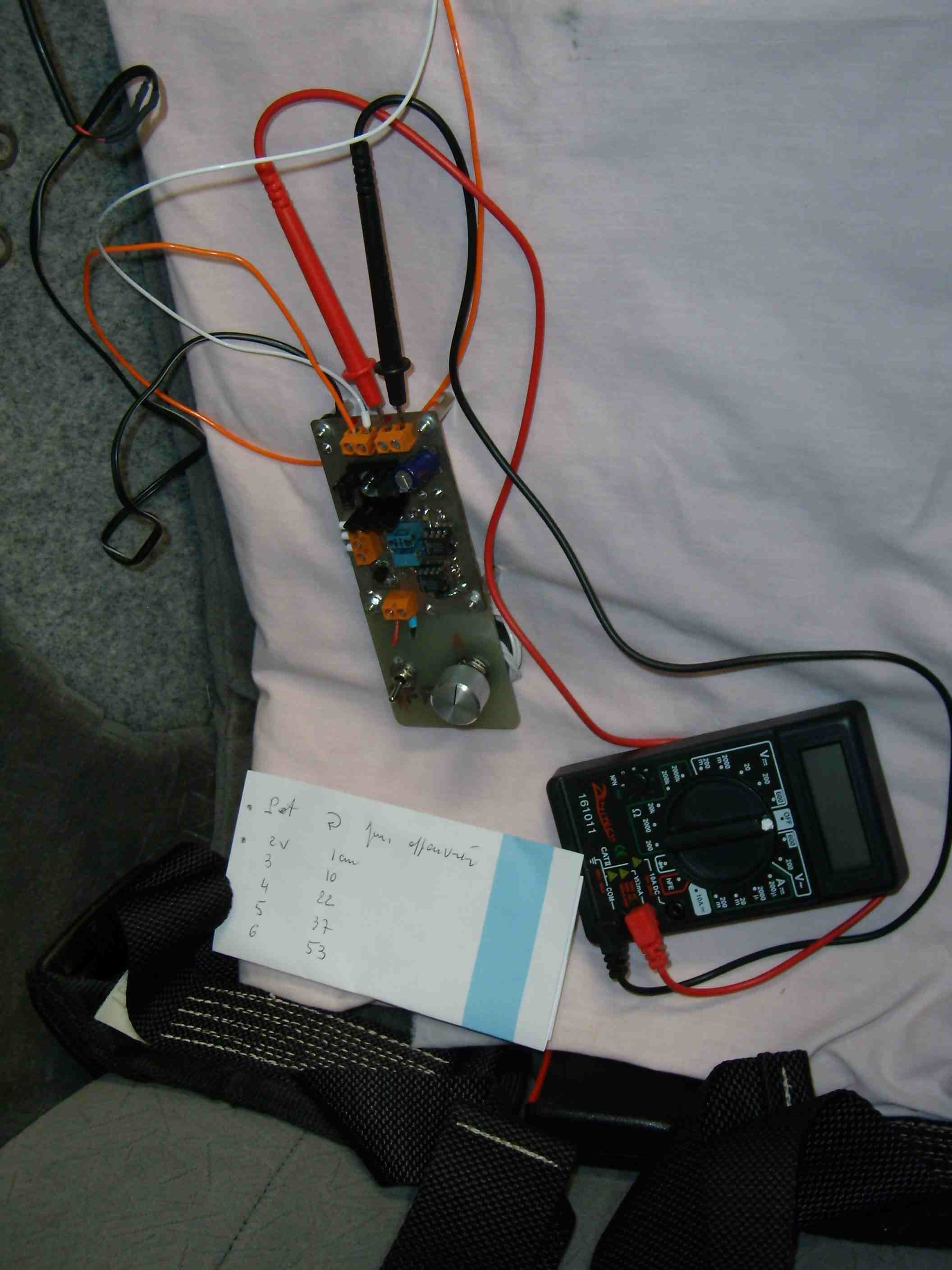

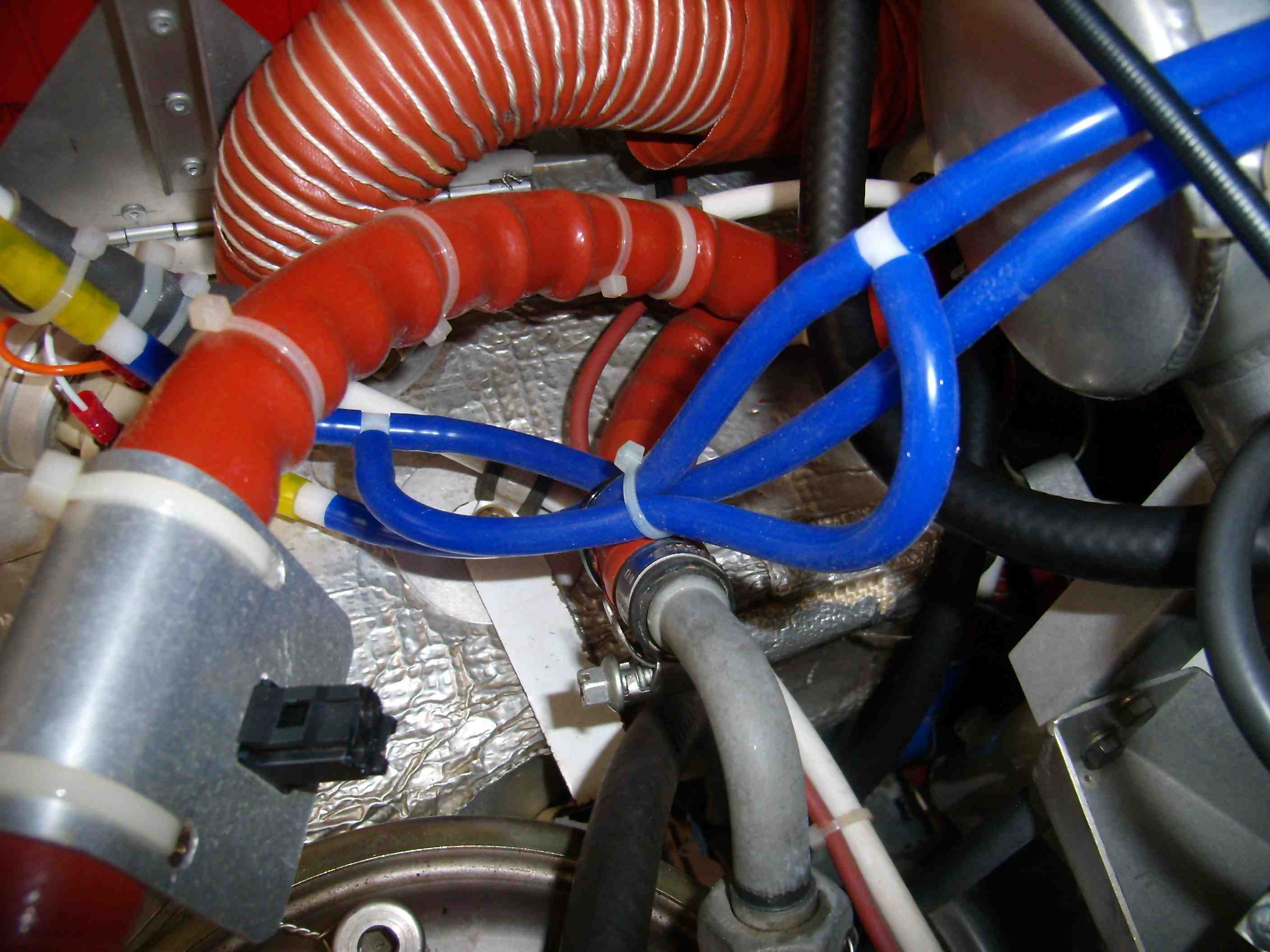

My system uses an electric fuel pump (Pierburg E1F p/n 7.21440.51.0) to create the vacuum. The vacuum side of the pump is connected to the two carb bowl vents and the pressure side is connected to the airbox, through a combination of polyurethane and silicone tubing, nylon tees and straight junctions. See attached pictures. The vacuum is adjusted using a potentiometer and some electronics to control the pump voltage. The actual voltage at the pump is being measured during testing.

Initial testing showed that the pump was way too powerful and I had to add a by-pass around it which incorporates a calibrated .8 mm restrictor, to reduce the effective vacuum. In order to calibrate the system on the bench, I measured the vacuum using a U shaped clear tubing filled with water. (btw I remember Colomban saying he was using red wine to better visualize the level). With the by-pass, the system provides the following vacuum levels: 3 volts at the pump=20mm H2O. 4V=30mm, 5.5V=40mm, up to 13V=220mm.

Testing on the aircraft (912ULS + Airmaster prop):

On the ground (altitude 2000ft): at 2700 RPM, progressively increasing the voltage at the pump, RPM increases and when reaching 4 volts the RPM peaks at 2900, then goes down and starts to run rough above 4V.

at 4000 RPM, progressively increasing the voltage, when reaching 4 volts the RPM decreases and engine starts to run rough.

In flight at 10000ft, full throttle, 5000 RPM, propeller in Manual mode to freeze the pitch, when reaching 4 volts the RPM decreases to 4900 and engine starts to run rough.

Interpretation of the results: the vacuum necessary to lean the mixture on a Rotax 912ULS at 10000ft is 30mm H2O approx.

Leaning on the ground at high idle increases the power, which means the idle mixture was way too rich.

Leaning at 10000ft does not increases the power at all. That means that, without leaning, the mixture is not rich enough to prevent the engine to deliver full power as it is with legacy aircraft engines. I suppose leaning would slightly reduce fuel flow of the Rotax at this altitude but I had no means of measuring the gain accurately and also no means of being sure I was not damaging the engine. That is why I stopped the experiment at this point.

Concerns regarding the pump: it is designed to pump fuel not air. In normal use I suppose the fuel cools and lubricates the pump. Pumping air, even at reduced voltage, the pump could be damaged. An alternative would be to use a ventilator. I found some ventilators which are able to provide the required static vacuum but I think there is a risk of overheating because there would be used at zero flow, which is not what there are designed for. Some endurance testing would be required to find out.

Compared to the Hacman, the electric leaning system has a few advantages: there is no modification of the carbs. It is fail safe: if the pump stops working your are back to the normal configuration where Carb bowl pressure equals air box pressure. In case of a problem, just switch it off.

Now why is the high altitude behaviour of the Rotax so different from the legacy aircraft engines? On Lycoming and Continental engines carburettors there is a power enrichment device (improperly called "economizer" by Marvel Schebler) which provides a lot richer mixture when the throttle nears the full forward position. This is necessary to better cool the cylinders heads to prevent detonation at full sea level power. At 10000ft, full throttle will give only about 55-65% power, depending on the prop, so the power enrichment is not necessary anymore. Then the power enrichment and the effect of air density combine to provide an extremely overrich mixture. At full rich at 10000ft, those engines will run rough and the spark plugs may foul if you do not lean. When leaning appropriately, you will see a very significant increase of power.

On the 912 and 912S, the figures provided by ROTAX in the Owner Manual show that the specific fuel consumption at full sea level power is the same as at cruise power. So obviously there is no power enrichment system. (there is one on the 914 but that is another story). The Rotax water cooled cylinder heads temp are a lot lower than those of the air cooled legacy engines and that makes detonation a lot less likely, therefore a richer mixture at full throttle is unnecessary. So at 10000 ft ,the 912 is running slightly too rich due to the reduced density but not to the point of limiting the available power. Flying at 16000 ft over the top of the Mont Blanc, the Rotax runs flawlessly. An appropriate leaning device would for sure provide some fuel saving at high altitude but more testing would be necessary to find out how much.

The attached photos show the pump installed on top of the starboard foot well, the connection to the carbs and airbox (blue and black tubing), the by-pass (blue tubing connected to two tees), the controller and voltmeter on the passenger seat.

Remi

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

241.35 KB |

| Viewed: |

9981 Time(s) |

|

| Description: |

|

| Filesize: |

352.83 KB |

| Viewed: |

9981 Time(s) |

|

| Description: |

|

| Filesize: |

216.3 KB |

| Viewed: |

9981 Time(s) |

|

| Description: |

|

| Filesize: |

218.27 KB |

| Viewed: |

9981 Time(s) |

|

| Description: |

|

Download |

| Filename: |

Correcteur altimétrique pour carbu BING 2.pdf |

| Filesize: |

158.92 KB |

| Downloaded: |

358 Time(s) |

| Description: |

|

Download |

| Filename: |

Correcteur altimétrique pour carbu BING 1.pdf |

| Filesize: |

128.14 KB |

| Downloaded: |

556 Time(s) |

|

|

| Back to top |

|

|

kingsnjan(at)westnet.com.

Guest

|

Posted: Wed Dec 18, 2019 11:00 pm Post subject: Hacman Gen 3 Mixture Control Posted: Wed Dec 18, 2019 11:00 pm Post subject: Hacman Gen 3 Mixture Control |

|

|

Remi,

When I requested more info from you I didn’t expect you to go to the trouble you have. Thank you so much.

I have my wife in hospital at this moment but when she is up and about again, I will give it more consideration than I have been able to thus far.

Thanks again Remi.

Kingsley

Sent from my iPhone

| Quote: | On 18 Dec 2019, at 1:29 am, Remi Guerner <air.guerner(at)orange.fr> wrote:

"if you have any info available which you would be

prepared to share on your leaning system Remi, I would very much

appreciate same please. "

Hello Kingsley,

First I want to say that I am not the inventor off the principle of creating a vacuum in the float bowl using an electric pump to lean the Bing carbs. This leaning device was designed about 20 years ago by Michel Colomban, designer of the Cri-Cri and MC100 on which the well known DynAero MCR series were based. He designed his own pump to create the vacuum. The vacuum is adjusted through a potentiometer and the mixture ratio is measured using an O2/ lambda probe. Attached are some original Colomban's drawings (in French, sorry)

My system uses an electric fuel pump (Pierburg E1F p/n 7.21440.51.0) to create the vacuum. The vacuum side of the pump is connected to the two carb bowl vents and the pressure side is connected to the airbox, through a combination of polyurethane and silicone tubing, nylon tees and straight junctions. See attached pictures. The vacuum is adjusted using a potentiometer and some electronics to control the pump voltage. The actual voltage at the pump is being measured during testing.

Initial testing showed that the pump was way too powerful and I had to add a by-pass around it which incorporates a calibrated .8 mm restrictor, to reduce the effective vacuum. In order to calibrate the system on the bench, I measured the vacuum using a U shaped clear tubing filled with water. (btw I remember Colomban saying he was using red wine to better visualize the level). With the by-pass, the system provides the following vacuum levels: 3 volts at the pump mm H2O. 4V=30mm, 5.5V=40mm, up to 13V=220mm.

Testing on the aircraft (912ULS + Airmaster prop):

On the ground (altitude 2000ft): at 2700 RPM, progressively increasing the voltage at the pump, RPM increases and when reaching 4 volts the RPM peaks at 2900, then goes down and starts to run rough above 4V.

at 4000 RPM, progressively increasing the voltage, when reaching 4 volts the RPM decreases and engine starts to run rough.

In flight at 10000ft, full throttle, 5000 RPM, propeller in Manual mode to freeze the pitch, when reaching 4 volts the RPM decreases to 4900 and engine starts to run rough.

Interpretation of the results: the vacuum necessary to lean the mixture on a Rotax 912ULS at 10000ft is 30mm H2O approx.

Leaning on the ground at high idle increases the power, which means the idle mixture was way too rich.

Leaning at 10000ft does not increases the power at all. That means that, without leaning, the mixture is not rich enough to prevent the engine to deliver full power as it is with legacy aircraft engines. I suppose leaning would slightly reduce fuel flow of the Rotax at this altitude but I had no means of measuring the gain accurately and also no means of being sure I was not damaging the engine. That is why I stopped the experiment at this point.

Concerns regarding the pump: it is designed to pump fuel not air. In normal use I suppose the fuel cools and lubricates the pump. Pumping air, even at reduced voltage, the pump could be damaged. An alternative would be to use a ventilator. I found some ventilators which are able to provide the required static vacuum but I think there is a risk of overheating because there would be used at zero flow, which is not what there are designed for. Some endurance testing would be required to find out.

Compared to the Hacman, the electric leaning system has a few advantages: there is no modification of the carbs. It is fail safe: if the pump stops working your are back to the normal configuration where Carb bowl pressure equals air box pressure. In case of a problem, just switch it off.

Now why is the high altitude behaviour of the Rotax so different from the legacy aircraft engines? On Lycoming and Continental engines carburettors there is a power enrichment device (improperly called "economizer" by Marvel Schebler) which provides a lot richer mixture when the throttle nears the full forward position. This is necessary to better cool the cylinders heads to prevent detonation at full sea level power. At 10000ft, full throttle will give only about 55-65% power, depending on the prop, so the power enrichment is not necessary anymore. Then the power enrichment and the effect of air density combine to provide an extremely overrich mixture. At full rich at 10000ft, those engines will run rough and the spark plugs may foul if you do not lean. When leaning appropriately, you will see a very significant increase of power.

On the 912 and 912S, the figures provided by ROTAX in the Owner Manual show that the specific fuel consumption at full sea level power is the same as at cruise power. So obviously there is no power enrichment system. (there is one on the 914 but that is another story). The Rotax water cooled cylinder heads temp are a lot lower than those of the air cooled legacy engines and that makes detonation a lot less likely, therefore a richer mixture at full throttle is unnecessary. So at 10000 ft ,the 912 is running slightly too rich due to the reduced density but not to the point of limiting the available power. Flying at 16000 ft over the top of the Mont Blanc, the Rotax runs flawlessly. An appropriate leaning device would for sure provide some fuel saving at high altitude but more testing would be necessary to find out how much.

The attached photos show the pump installed on top of the starboard foot well, the connection to the carbs and airbox (blue and black tubing), the by-pass (blue tubing connected to two tees), the controller and voltmeter on the passenger seat.

Remi

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=493867#493867

Attachments:

http://forums.matronics.com//files/p9050002a_2_155.jpg

http://forums.matronics.com//files/p9050004a_2_148.jpg

http://forums.matronics.com//files/p9050005a_2_501.jpg

http://forums.matronics.com//files/p9050006__copie_662.jpg

http://forums.matronics.com//files/correcteur_altimtrique_pour_carbu_bing_2_540.pdf

http://forums.matronics.com//files/correcteur_altimtrique_pour_carbu_bing_1_196.pdf

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

captaincooper

Joined: 05 May 2020

Posts: 3

Location: Australia

|

Posted: Fri May 08, 2020 12:45 am Post subject: Re: Hacman Gen 3 Mixture Control Posted: Fri May 08, 2020 12:45 am Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

| kingsnjan(at)westnet.com. wrote: | Group,

Does anybody have any experience with the Hacman Gen 3 Mixture Control

on their 912 or 912S please?

Reason is that I am astounded how much more fuel my 912 (80 HP) burns at

altitude than when low down. eg. At altitude where the MAP is say 20"

at wide open throttle and 5000 rpm, the fuel flow is 17-18 LPH while on

the same power setting (20" and 5000 rpm) at 2500 ft, the fuel flow is

12-13 LPH. I have discovered that at altitude with WOT, if I throttle

back until the MAP "just" starts to drop, the fuel flow will drop back

approx 1 LPH.

If the Hacman unit works, I am interested in procuring one.

Many thanks

Have you installed it? I just bought one for my 912ULS but they sent me the Jabiru kit instead. I’ve emailed and phoned to get the

Right part but get no reply. I have installed it but don’t know if I can modify the 90° barb out to the filter and orifice. I don’t know what size orifice to drill.

Kingsley from Oz |

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

969.5 KB |

| Viewed: |

9376 Time(s) |

|

_________________

Coop |

|

| Back to top |

|

|

captaincooper

Joined: 05 May 2020

Posts: 3

Location: Australia

|

Posted: Tue May 12, 2020 2:22 pm Post subject: Re: Hacman Gen 3 Mixture Control Posted: Tue May 12, 2020 2:22 pm Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

| Remi Guerner wrote: | "if you have any info available which you would be

prepared to share on your leaning system Remi, I would very much

appreciate same please. "

Hello Kingsley,

First I want to say that I am not the inventor off the principle of creating a vacuum in the float bowl using an electric pump to lean the Bing carbs. This leaning device was designed about 20 years ago by Michel Colomban, designer of the Cri-Cri and MC100 on which the well known DynAero MCR series were based. He designed his own pump to create the vacuum. The vacuum is adjusted through a potentiometer and the mixture ratio is measured using an O2/ lambda probe. Attached are some original Colomban's drawings (in French, sorry)

My system uses an electric fuel pump (Pierburg E1F p/n 7.21440.51.0) to create the vacuum. The vacuum side of the pump is connected to the two carb bowl vents and the pressure side is connected to the airbox, through a combination of polyurethane and silicone tubing, nylon tees and straight junctions. See attached pictures. The vacuum is adjusted using a potentiometer and some electronics to control the pump voltage. The actual voltage at the pump is being measured during testing.

Initial testing showed that the pump was way too powerful and I had to add a by-pass around it which incorporates a calibrated .8 mm restrictor, to reduce the effective vacuum. In order to calibrate the system on the bench, I measured the vacuum using a U shaped clear tubing filled with water. (btw I remember Colomban saying he was using red wine to better visualize the level). With the by-pass, the system provides the following vacuum levels: 3 volts at the pump=20mm H2O. 4V=30mm, 5.5V=40mm, up to 13V=220mm.

Testing on the aircraft (912ULS + Airmaster prop):

On the ground (altitude 2000ft): at 2700 RPM, progressively increasing the voltage at the pump, RPM increases and when reaching 4 volts the RPM peaks at 2900, then goes down and starts to run rough above 4V.

at 4000 RPM, progressively increasing the voltage, when reaching 4 volts the RPM decreases and engine starts to run rough.

In flight at 10000ft, full throttle, 5000 RPM, propeller in Manual mode to freeze the pitch, when reaching 4 volts the RPM decreases to 4900 and engine starts to run rough.

Interpretation of the results: the vacuum necessary to lean the mixture on a Rotax 912ULS at 10000ft is 30mm H2O approx.

Leaning on the ground at high idle increases the power, which means the idle mixture was way too rich.

Leaning at 10000ft does not increases the power at all. That means that, without leaning, the mixture is not rich enough to prevent the engine to deliver full power as it is with legacy aircraft engines. I suppose leaning would slightly reduce fuel flow of the Rotax at this altitude but I had no means of measuring the gain accurately and also no means of being sure I was not damaging the engine. That is why I stopped the experiment at this point.

Concerns regarding the pump: it is designed to pump fuel not air. In normal use I suppose the fuel cools and lubricates the pump. Pumping air, even at reduced voltage, the pump could be damaged. An alternative would be to use a ventilator. I found some ventilators which are able to provide the required static vacuum but I think there is a risk of overheating because there would be used at zero flow, which is not what there are designed for. Some endurance testing would be required to find out.

Compared to the Hacman, the electric leaning system has a few advantages: there is no modification of the carbs. It is fail safe: if the pump stops working your are back to the normal configuration where Carb bowl pressure equals air box pressure. In case of a problem, just switch it off.

Now why is the high altitude behaviour of the Rotax so different from the legacy aircraft engines? On Lycoming and Continental engines carburettors there is a power enrichment device (improperly called "economizer" by Marvel Schebler) which provides a lot richer mixture when the throttle nears the full forward position. This is necessary to better cool the cylinders heads to prevent detonation at full sea level power. At 10000ft, full throttle will give only about 55-65% power, depending on the prop, so the power enrichment is not necessary anymore. Then the power enrichment and the effect of air density combine to provide an extremely overrich mixture. At full rich at 10000ft, those engines will run rough and the spark plugs may foul if you do not lean. When leaning appropriately, you will see a very significant increase of power.

On the 912 and 912S, the figures provided by ROTAX in the Owner Manual show that the specific fuel consumption at full sea level power is the same as at cruise power. So obviously there is no power enrichment system. (there is one on the 914 but that is another story). The Rotax water cooled cylinder heads temp are a lot lower than those of the air cooled legacy engines and that makes detonation a lot less likely, therefore a richer mixture at full throttle is unnecessary. So at 10000 ft ,the 912 is running slightly too rich due to the reduced density but not to the point of limiting the available power. Flying at 16000 ft over the top of the Mont Blanc, the Rotax runs flawlessly. An appropriate leaning device would for sure provide some fuel saving at high altitude but more testing would be necessary to find out how much.

The attached photos show the pump installed on top of the starboard foot well, the connection to the carbs and airbox (blue and black tubing), the by-pass (blue tubing connected to two tees), the controller and voltmeter on the passenger seat.

Remi |

I’m very interested in your tests. I’m thinking of installing a vacuum pump to achieve same results. I’m not sure what 30mm H20 is in psi?

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Coop |

|

| Back to top |

|

|

Remi Guerner

Joined: 14 Dec 2010

Posts: 284

|

Posted: Wed May 13, 2020 12:01 am Post subject: Re: Hacman Gen 3 Mixture Control Posted: Wed May 13, 2020 12:01 am Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

<<>>>

Coop,

30mm H2o= .043 PSI

That is an extremely low pressure.

I am working on a new device using an small axial fan to generate the succion. It works very well on the bench. I will test it in flight within the next few weeks and will come back with the results.

Remi

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

captaincooper

Joined: 05 May 2020

Posts: 3

Location: Australia

|

Posted: Wed May 13, 2020 1:09 am Post subject: Re: Hacman Gen 3 Mixture Control Posted: Wed May 13, 2020 1:09 am Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

Look forward to hearing. I bought a micro suction pump to try out also. Won’t arrive for two months though, but will let you know.

I find with the hacman taking its suction from the Venturi runs out of suction and I can’t get to peak EGT

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Coop |

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 780

|

Posted: Wed May 13, 2020 11:37 am Post subject: Re: Hacman Gen 3 Mixture Control Posted: Wed May 13, 2020 11:37 am Post subject: Re: Hacman Gen 3 Mixture Control |

|

|

Hi Kingsley

You wrote To my knowledge, the Bing Carb has no power jet. A 914 doesn't have a power jet but it does have a hand in breeze. When requesting war emergency power an enriching solenoid does exactly opposite of what a Hacman does and increases pressure to float bowl and enriches the mixture. It does this by instead of plumbing float bowl to airbox pressure, it plumbs it to an area of higher pressure than the airbox pressure. 914 is very dependent on float bowl gasket not leaking. I'm going Viton gasket and 912 wire bale and not overtorque bowl and bend float bowl. I imagine with a 912 or 912S with Hacman float bowl seal is more important than without?

Ron P.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|