|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

art(at)zemon.name

Guest

|

Posted: Sun Apr 24, 2016 11:55 am Post subject: Check My Work Posted: Sun Apr 24, 2016 11:55 am Post subject: Check My Work |

|

|

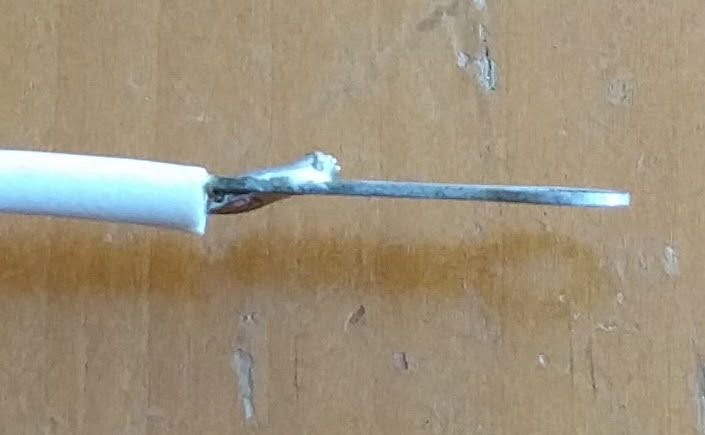

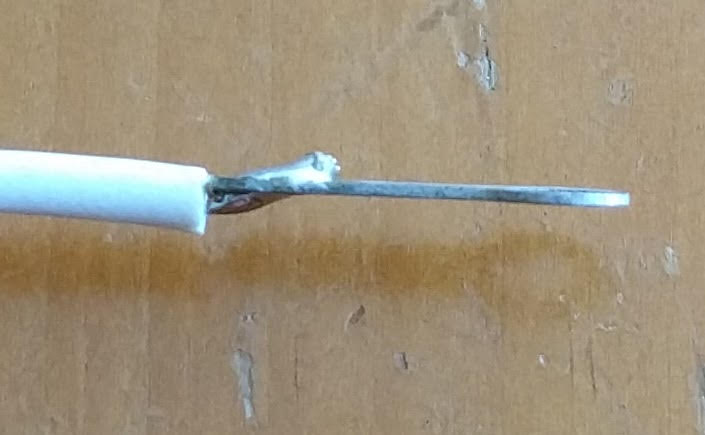

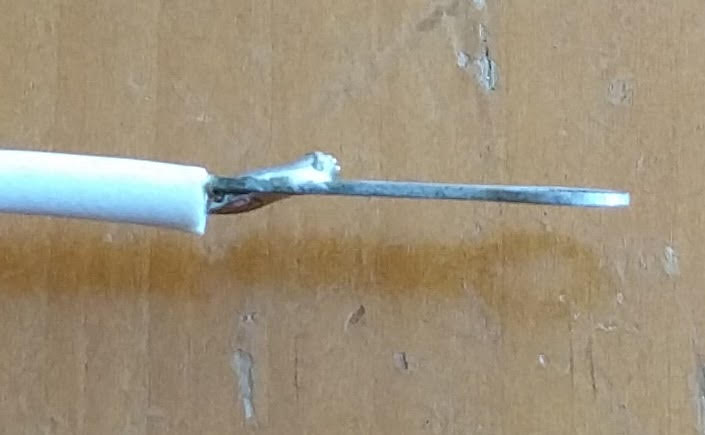

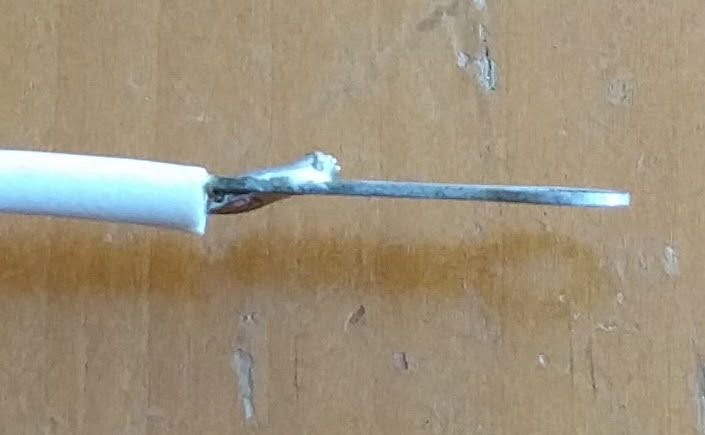

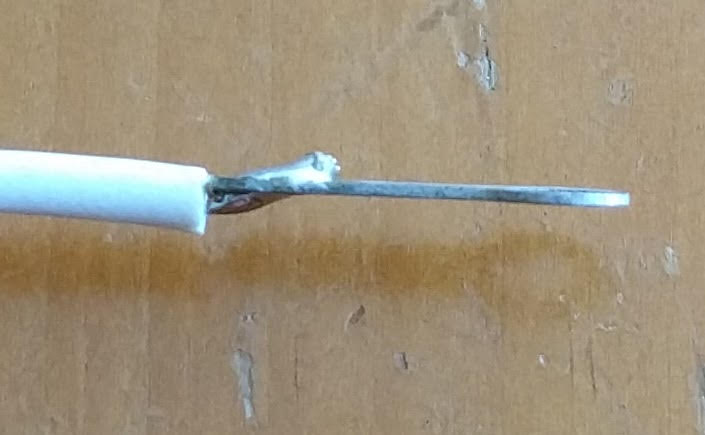

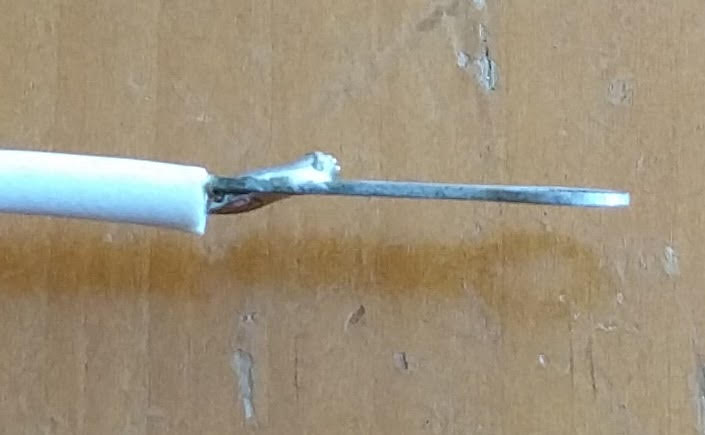

I found some old dogbone connectors in the basement and have been doing some practicing. Googling didn't turn up any examples of a well soldered joint so please give me some feedback. (I did find a YouTube video of someone teaching soldering... he had a roll of electrical tape!) The wire is 20 AWG in this sample:

[img]cid:ii_inezoyo40_15449d2b2cf72449[/img]

[img]cid:ii_inezoyot1_15449d2b2cf72449[/img]

[img]cid:ii_inezoypa2_15449d2b2cf72449[/img]

Is that how it should look?

BTW, it is a pure delight to use the WES51. I have never bought anything better than a $25 soldering pencil for myself. I wish I could have afforded something like this back when I was in junior high and in high school and was building lots o' stuff.

Thanks,

-- Art Z.

--

http://CheerfulCurmudgeon.com/"If I am not for myself, who is for me? And if I am only for myself, what am I? And if not now, when?" Hillel

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

31.33 KB |

| Viewed: |

4098 Time(s) |

|

| Description: |

|

| Filesize: |

51.2 KB |

| Viewed: |

4098 Time(s) |

|

| Description: |

|

| Filesize: |

43.57 KB |

| Viewed: |

4098 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Apr 24, 2016 12:57 pm Post subject: Check My Work Posted: Sun Apr 24, 2016 12:57 pm Post subject: Check My Work |

|

|

At 02:53 PM 4/24/2016, you wrote:

| Quote: | | I found some old dogbone connectors in the basement and have been doing some practicing. Googling didn't turn up any examples of a well soldered joint so please give me some feedback. (I did find a YouTube video of someone teaching soldering... he had a roll of electrical tape!) The wire is 20 AWG in this sample: |

That joint is probably quite adequate. There

are some signs of 'beading' for the molten

solder at the interface with the terminal . . .

an effect of terminals exposed to the air

and moisture for some time . . . solder

has difficulty getting an aggressive wetting.

The really BIG difference in solders has more

to do with flux than the alloy. There are

really 'active' fluxes that would produce

a more wetted joint but I wouldn't be afraid

of what you've produced.

One thing you might 'practice' with is a technique

I call "flushing" the joint. Put some heat to the

terminal as if you were going to 'tin' the

end . . . but push some solder into the melt

until it drips, then wipe it off with rag before

it cools. Some solders I have are very active

flux and the excess melt+flux goes a long

way to preparing the base metal to accept

the soldered wire. You wind up using perhaps

2x to 3x of solder necessary to complete

the joint but the act of flushing with some

excess melt + flux can be useful to the

finished joint on 'stale' surfaces.

That's something you can play with but what

you've shown us is certainly adequate.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Apr 24, 2016 1:17 pm Post subject: Check My Work Posted: Sun Apr 24, 2016 1:17 pm Post subject: Check My Work |

|

|

At 03:56 PM 4/24/2016, you wrote:

| Quote: | At 02:53 PM 4/24/2016, you wrote:

| Quote: | | I found some old dogbone connectors in the basement and have been doing some practicing. Googling didn't turn up any examples of a well soldered joint so please give me some feedback. (I did find a YouTube video of someone teaching soldering... he had a roll of electrical tape!) The wire is 20 AWG in this sample: |

That joint is probably quite adequate. There

are some signs of 'beading' for the molten

solder at the interface with the terminal . . .

an effect of terminals exposed to the air

and moisture for some time . . . solder

has difficulty getting an aggressive wetting. |

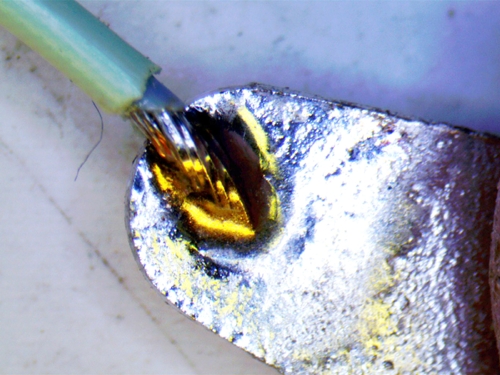

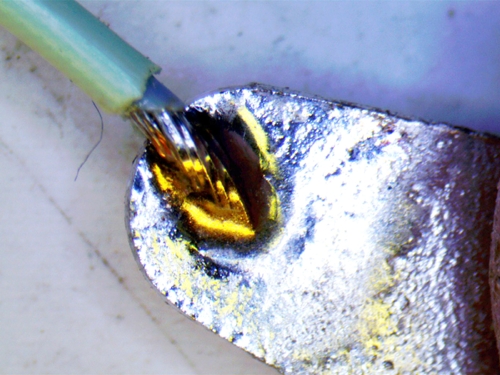

You're looking for something more like this:

[img]cid:.0[/img]

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

170.97 KB |

| Viewed: |

4098 Time(s) |

|

| Description: |

|

| Filesize: |

501.09 KB |

| Viewed: |

4098 Time(s) |

|

|

|

| Back to top |

|

|

art(at)zemon.name

Guest

|

Posted: Sun Apr 24, 2016 2:55 pm Post subject: Check My Work Posted: Sun Apr 24, 2016 2:55 pm Post subject: Check My Work |

|

|

Bob,

Flushing... never heard of it. I just tried it on one of those old connectors and I did get a much better joint.Â

My practice connectors, BTW, have been in my basement for more than 20 years. They are heavily oxidized. I wouldn't put them into my plane but they are proving worthy experimentation fodder.

Oh... before I forget again... some of the photos on Poor Man's Solder Sleeves don't load. I was able to make a very satisfactory splice following your instructions on that page. I am now ready to cut and extend the CAN bus link cable that came with my MGL autopilot servo.

Thank you for your mentoring and encouragement.

-- Art Z.

On Sun, Apr 24, 2016 at 3:56 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | Â One thing you might 'practice' with is a technique

I call "flushing" the joint. Put some heat to the

terminal as if you were going to 'tin' the

end . . . but push some solder into the melt

until it drips, then wipe it off with rag before

it cools. Some solders I have are very active

flux and the excess melt+flux goes a long

way to preparing the base metal to accept

the soldered wire. You wind up using perhaps

2x to 3x of solder necessary to complete

the joint but the act of flushing with some

excess melt + flux can be useful to the

finished joint on 'stale' surfaces.

|

--

http://CheerfulCurmudgeon.com/"If I am not for myself, who is for me? And if I am only for myself, what am I? And if not now, when?" Hillel

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Apr 24, 2016 7:17 pm Post subject: Check My Work Posted: Sun Apr 24, 2016 7:17 pm Post subject: Check My Work |

|

|

At 05:54 PM 4/24/2016, you wrote:

| Quote: | Bob,

Flushing... never heard of it. |

You wouldn't . . . in the higher order

environs of manufacturing with bright,

new components. But for those of us who

date back to 6v mobile rigs running

vibrators and PE-103 dynamoters all

scrounged from WWII military surplus,

a few 'tricks of the trade' were

discovered.

| Quote: | I just tried it on one of those old connectors and I did get a much better joint.Â

My practice connectors, BTW, have been in my basement for more than 20 years. They are heavily oxidized. I wouldn't put them into my plane but they are proving worthy experimentation fodder. |

Sure . . . but should you wish to use

one, pulling the soldered end out of a

firm grip in ScotchBright will improve

the wetting too.

| Quote: | Oh... before I forget again... some of the photos on Poor Man's Solder Sleeves don't load. I was able to make a very satisfactory splice following your instructions on that page. I am now ready to cut and extend the CAN bus link cable that came with my MGL autopilot servo.

|

I just checked them here and they came

down alright . . . sorry you're having

difficulty.

| Quote: | | Thank you for your mentoring and encouragement. |

Thank us here on the List by getting better

at what you do . . . but you are indeed

most welcome.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Mon Apr 25, 2016 10:54 am Post subject: Check My Work Posted: Mon Apr 25, 2016 10:54 am Post subject: Check My Work |

|

|

At first glance, that pic shows a poor solder joint.

The wire is captured correctly but, the joint to the terminal is poor. The solder should pool out in a graceful way and appear very attached. Sometimes best to lightly sand the terminal metal first so solder can attach to base metal.

D

[quote] ---

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

43.57 KB |

| Viewed: |

4080 Time(s) |

|

| Description: |

|

| Filesize: |

31.33 KB |

| Viewed: |

4080 Time(s) |

|

| Description: |

|

| Filesize: |

51.2 KB |

| Viewed: |

4080 Time(s) |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Mon Apr 25, 2016 10:59 am Post subject: Check My Work Posted: Mon Apr 25, 2016 10:59 am Post subject: Check My Work |

|

|

Oops. . . I probably spoke out of turn.

I did not see the 2nd image where the wire passes thru and is soldered on both sides. That joint maybe Ok. . The only flaw is that I cannot see the smooth fan-out of the solder edges. It looks like the solder is fighting against some sort of plating on the terminal. On a joint like that, I would probably try to flow some solder on the terminal first. Just enough to get a wet look but, not enough to block the wire hole. If that flows normally, then attach the wire and flow additional material to bind it all in one unit.

[quote] ---

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

43.57 KB |

| Viewed: |

4080 Time(s) |

|

| Description: |

|

| Filesize: |

31.33 KB |

| Viewed: |

4080 Time(s) |

|

| Description: |

|

| Filesize: |

51.2 KB |

| Viewed: |

4080 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|